Voortman VP Range

Painting beams and plates

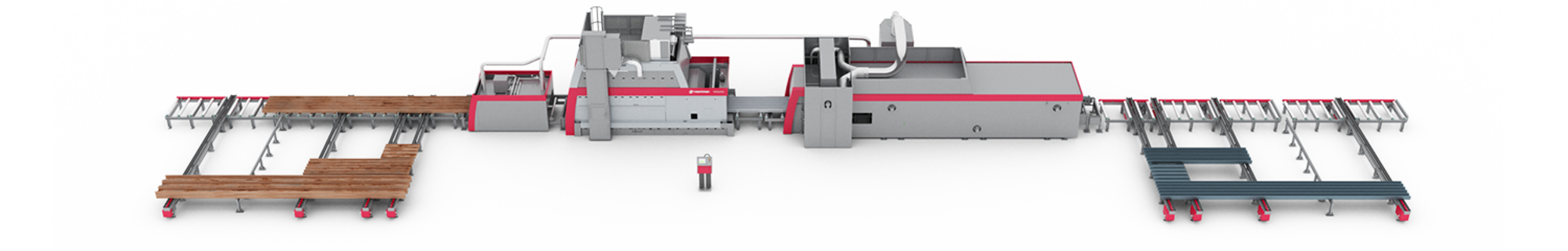

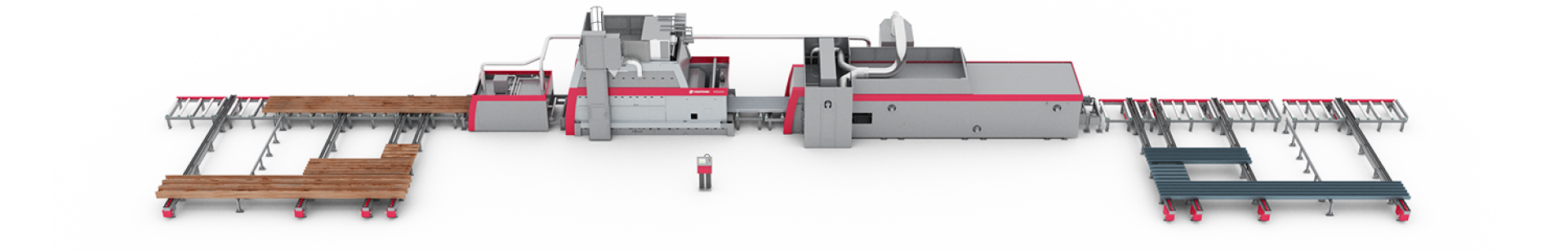

The Voortman VP Range painting machine is designed to automatically paint steel plates and profiles. The VP Range can be combined with other Voortman surface treatment machines, such as a blow-off unit, pre-heater, shot blasting machine, and a drying tunnel. Combining surface treatment machines in one connected line increases production output while reducing required floor space.

ONLY PAINT WHEN MATERIAL IS PRESENT

The VP Range painting machine automatically detects the material dimensions, so it only sprays paint when material is present. This reduces wear on the machine and saves on paint consumables cost

AUTOMATIC HEIGHT ADJUSTMENT

A light barrier near the infeed measures material before entering the VP Range. Then, the upper paint trolley automatically adjusts to the correct height to guarantee an accurate painting process.

Voortman offers a complete surface treatment line that prepares your products for storage and/or further processing. The VP Primer and VSB Shot blaster can be placed back-to-back to save time, costs and handling space requirements in your production facility. The surface treatment line can be placed at the beginning or end of a Voortman processing line depending on the line’s purpose and goal, workshop layout and steel conditions.

INTEGRATION IN YOUR WORKSHOP

Voortman offers a complete surface treatment line that prepares your products for storage and/or further processing. The VP Primer and VSB Shot blaster can be placed back-to-back to save time, costs and handling space requirements in your production facility. The surface treatment line can be placed at the beginning or end of a Voortman processing line depending on the line’s purpose and goal, workshop layout and steel conditions.

If necessary, a pre-heater and drying tunnel can be added to the surface treatment line. Depending on your output requirements and the size of the profiles, a surface treatment line can be chosen to match. The line is completely autonomous with automatic infeed and outfeed, allowing your operators to focus on feeding and unloading the system.

Related

articles

Specifications

| Voortman VP Range | |||

|---|---|---|---|

| VP1500-4 | VP2500-4 | ||

| Entrance dimensions | inch | 5-1/4 x 2 | 8-1/2 x 2 |

| Plate width | inch | 59 | 98-1/2 |

| Profiles | inch | 50-3/6 x 20 | 50-3/6 x 20 |

| Painting speed | f/min | 2-1/4 - 9-3/16 | 2-1/4 - 8-3/16 |

| Airless spray guns | pcs | 4 | 4 |

| Solvent based paint | yes | ||

| Water based paint | yes | ||