Home | Products | Voortman Pipe Cutting Unit

VOORTMAN | PIPE CUTTING UNIT

Imagine this. Your stock of pipe parts is running low. Supplier delivery times don't fit your schedule. What now? Meet the Voortman Pipe Cutting Unit, which is the only one in the world working with its own TrueVolt principle for unparalleled cutting quality. You are less dependent on supply and keep control over your planning. The pipe is always visible first in 3D. A ready-made cutting product is prepared. Pipe cutting at your convenience. Do you already have a V303, V304 or V310 plate processing machine? Add the Voortman Pipe Cutting Unit. Easy to integrate and the low x-rail gives plenty of space. Or choose drilling, milling, plate cutting and pipe cutting all at once. Highest achievable quality and variety of shapes.

BEST CUTTING QUALITY

IN THE MARKET

EASILY INTEGRATED

AND USABLE

SAVE TIME

ON LOGISTICS

LESS DEPENDENT

ON SUPPLIERS

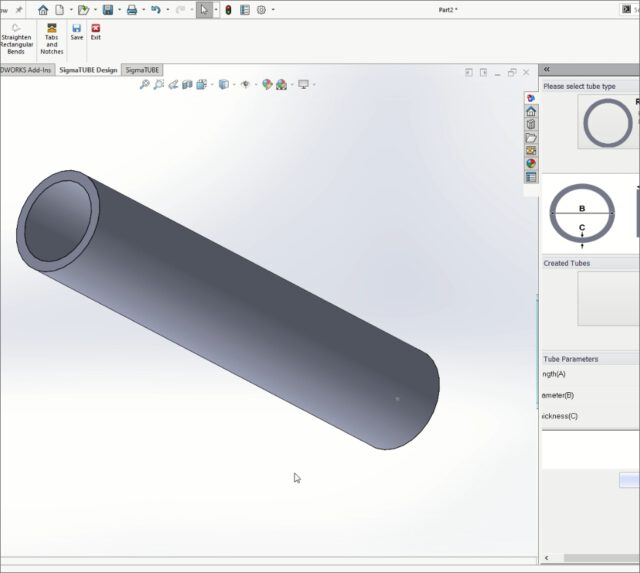

It's simple. Take a Voortman V303, V310 or V304 plate processing machine. You add the pipe cutting unit. This option fits into the working environment of the plate processing machine. Or are you looking for a new plate processing machine, including the pipe cutting unit. The software is SigmaTUBE, where a license for SolidWorks is included.

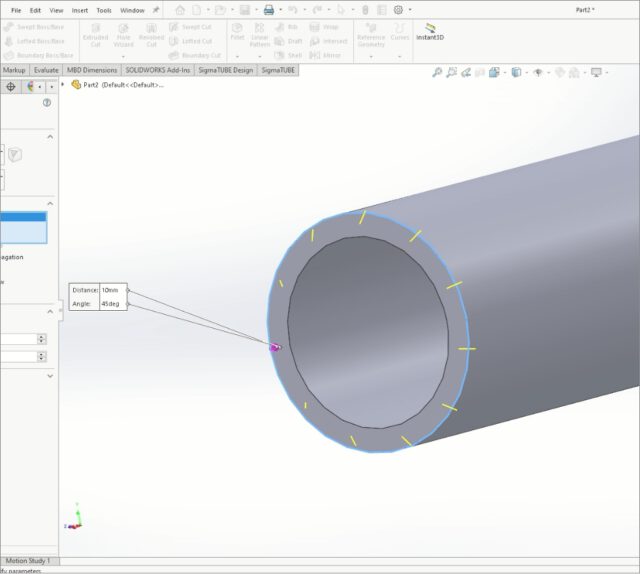

From your familiar operator panel, you operate the pipe cutting machine. That’s it. It's a small investment for less welding and grinding. Less correction welding. Cutting the right height without the need for mechanical assistance. The operator only needs to load the pipe.

WEBINAR / Voortman & Hypertherm

BECOMING A BEVEL CUTTING PRO!

Voortman and Hypertherm have collaborated to share their collective knowledge, tips and expertise in creating high-quality bevel cuts and weld preparations. Learn how to create perfect long bevel cuts and why elements like height control, programming sequences and deck maintenance are essential.

FLEXIBLE IMPORTING AND PROGRAMMING

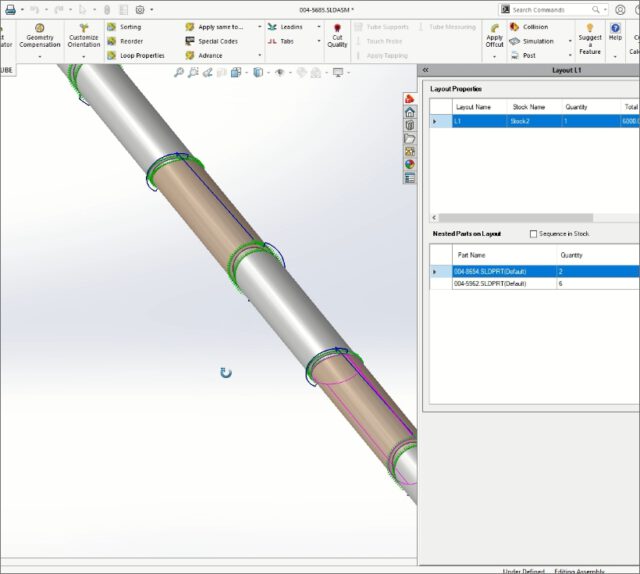

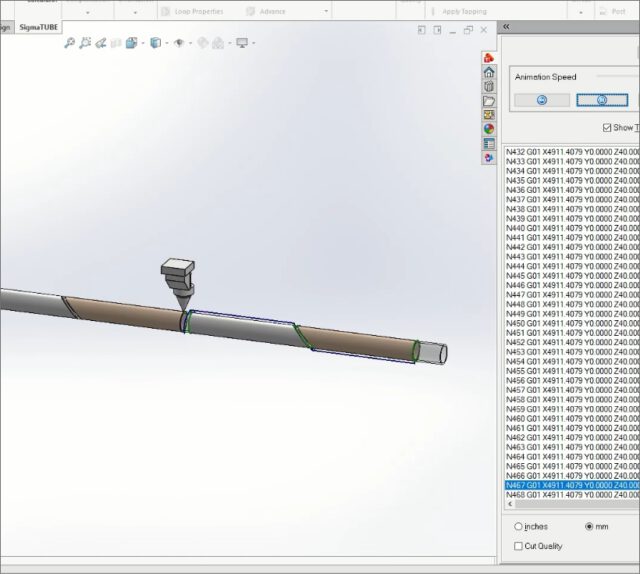

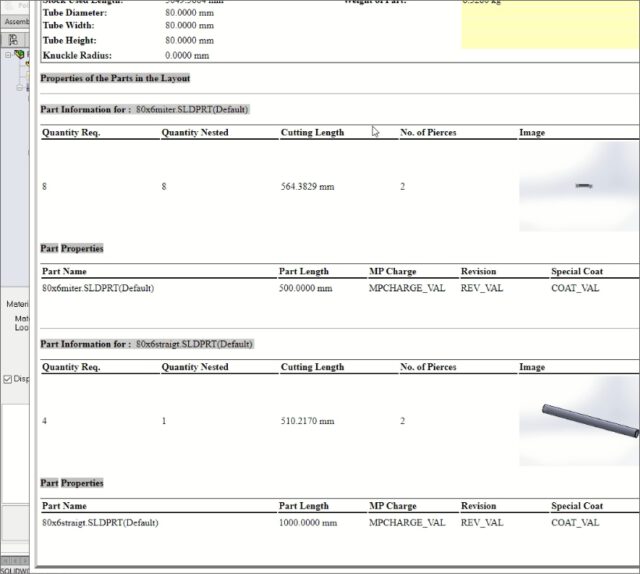

You are unburdened. Or, in other words, the operator can immediately put together a digital nesting to cut the pipe. Minimal preparation is required. That has already been done by the engineer and the work planner. The engineer draws the product or construction. The file is imported into SigmaTUBE. It has become a ready drawn cutting product. Made visual. The pipe can be seen in 3D. No time spent on programming. Faster switching. The work planner gets the STEP-file from the engineer.

All (3D) information that one needs to know to produce is in the STEP-file. From the STEP-file one programs in SigmaTUBE. The standard functions always give the operator a handhold. Weld preparations, contours and markings can be assessed in advance. All information is available. Just specify the numbers per product and SigmaTUBE will take care of the most optimal nesting. That is the starting point.

NEST EFFICIENT

Creating peace of mind. Seeing what's going well and what's not, before you definitively start nesting. A check in 3D. Ready for production. You see a simulation of how the pipe is laid out with products. Immediate correction is possible in order not to waste anything. A simulation of the pipe, what can or cannot be done gives optimal insight to minimize waste.

A 3D model which is created and becomes reality. Of course, you can print a report of the nesting. Information about the expected cutting time, planning, which products, sorting and the correct pipe length provides an overview. The operator places the correct pipe in the clamping of the pipe cutting unit. He selects the right nesting. One push of a button and your toolpath is ready. It's so easy.

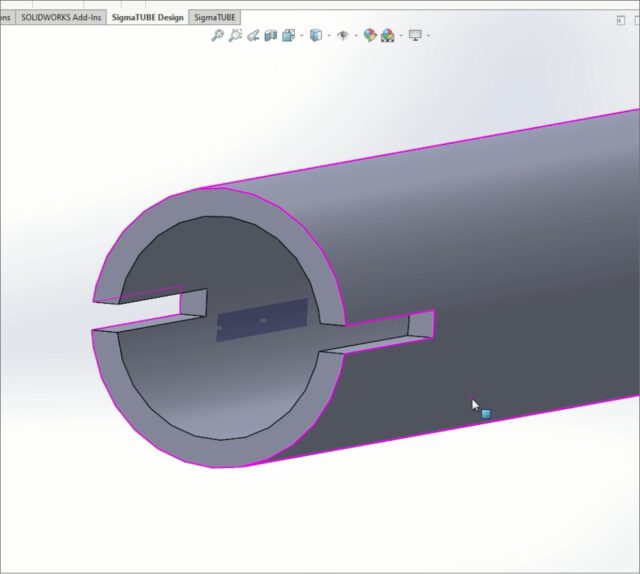

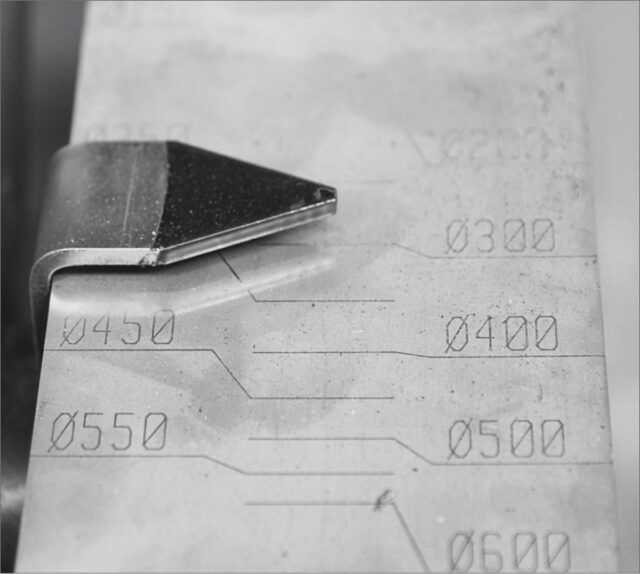

CUT LIKE NO ONE CAN

Accurate work at last. You may be used to mechanical pipe cutting. It all runs like clockwork, but you are missing the most optimal cutting quality you need. The pipe is egg-shaped or banana-shaped. Not nicely rounded and you see that reflected in the cutting quality. You want consistent quality, regardless of possible deformations of your pipe. A wide variety of sizes and weights to cut.

Voortman as the only one in the world - uses its own TrueVolt principle. A constant measurement based on arc voltage, so that the torch always cuts at the right height regardless of the thickness of the material. This guarantees constant quality and saves considerably on costs and consumables. Especially for tube cutting, the TrueVolt principle has been extended to include a predictive model of parameters based on the complete cut. The combination of prediction and real-time measurement is unique in this industry. With this height control, you get the most optimal cutting quality. Always.

ACCESSIBLE LOADING AND UNLOADING

That's easy work. The low x-rail gives room to load a pipe in the clamping. Easily accessible to level yourself. The extra wide supports are ready to support any weight. The visual indicator helps you to instantly determine the height. This pipe cutting unit provides a reduced dead zone per pipe. The machine indicates when the product is ready. To then move on to the next point. To cut a new finished product.

Available with

these machines

SPECIFICATIONS OF THE PIPE CUTTING UNIT

| Voortman Pipe Cutting Unit | ||

|---|---|---|

| Minimum size pipe straight cutting | inch | 2 |

| Minimum size pipe bevel cutting 45° | inch | 7 |

| Maximum size pipe | inch | 24 |

| Minimum wall thickness pipe | inch | 0.125 |

| Maximum wall thickness pipe | inch | 1 1/4 |

| Maximum length pipe | feet | 20 / 40 |

| Minimum raw length pipe | feet | 3 |

| Maximum weight pipe | lbs | 6,600 lbs or 1,800 libbre/piedi |

| Maximum weight per support (up to 450mm / up to 17-3/4”): | lbs | 3,300 |

| Maximum weight per support (450mm up to 610mm / 17.750” up to 24.000”): | lbs | 1,650 |