Home | Knowledgebase| Benefit from in-house developing

WE ARE VOORTMAN STEEL MACHINERY

Manufacturer of high quality CNC steel processing machines. Forward thinking, automation and quality are pillars reflected in everything we do.

Also when it comes to our plate processing machines and solutions. From in-house assembling and testing to in-house production of the robust machine frames, cutting tables and cabinets - we have everything in control, allowing us to deliver constant quality. But where's great hardware without great software? That's where our in-house developed VACAM software comes in and where we're always pushing boundaries. In our software development we focus on interaction, automation and machine feedback to ease your operator and maximize machine uptime and efficiency.

We're known for our excellent service and a beautiful Voortman Experience Center right here on our campus! An ideal location to visit and see our machines in action and speak with our experts about optimizing output and reducing your operational costs!

OPTIMIZE YOUR WORKFLOW AND REDUCE COSTS PER PART WITH VOORTMAN'S CNC PLATE PROCESSING MACHINES

BENEFIT FROM OUR IN-HOUSE DEVELOPMENT

ELECTRICAL CABINETS

In-house engineering

Our electrical engineers use 3D-CAD to create an electrical engineering plan. Assembly lines can use this data to automatically put cabinets together. Wires are automatically cut to length, sorted and numbered. Based on the three-dimensional visualizations, the panel is easily assembled. In this way we guarantee error-free products and at the same time we reduce delivery times significantly.

"Based on the three-dimensional visualizations, the panel is easily assembled."

PLATE CUTTING TABLES

Inhouse engineering and manufacturing

Having our own manufacturing plant allows us to identify with your challenges and puts us in a position to provide rapid solutions.

Our in-house developed and manufactured cutting tables feature a built-in drilling deck that prevents drill tips from breaking.

The new cutting table has a minimum number of components, easy liftable cleaning bins and fixation parts placed outside the cutting section, all of which contribute to cutting table users having 30% less time to clean.

"...all of which contribute to cutting table users having 30% less time to clean."

PLATE CUTTING MACHINES

Our machines process our machines

We design and manufacture plate processing machines for the manufacturing and machine building industries. Therefore, we use our own machines to build our machines. You can see why we are proud of our machines. Our double-gantry plate processing machines produce the frames that are welded together, milled, and coated by our craftsmen. We value efficiency and foster self-sufficiency.

"Our double-gantry plate processing machines produce the frames that are welded together, milled, and coated by our craftsmen."

MACHINE ASSEMBLING & TESTING

Carefully performed by professionals

The production of plate processing machines is broken down into a series of stages: mechanics, electronics and modules. In a single assembly line people are working passionately on our products.

At the end of the production process, the product is thoroughly tested. Under the watchful eye of all stakeholders, we ensure that it conforms to set tolerances and standards.

"In a single assembly line people are working passionately on our products."

VACAM: DEVELOPED AND CONTINUALLY SUPPORTED BY VOORTMAN

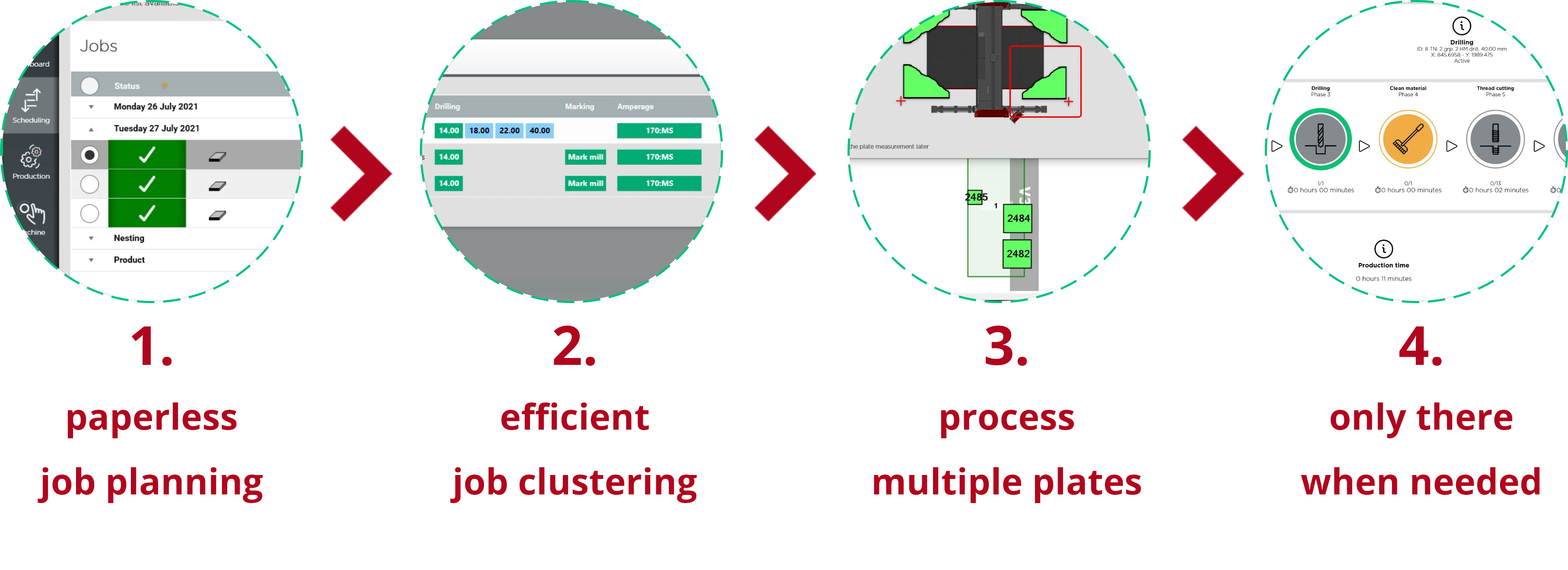

Every Voortman machine is equipped with our in-house developed VACAM control software. All machines share the same “look-and-feel”, reducing the learning curve. VACAM's open platform allows seamless exchange of production data with third party MRP software, providing up-to-date insight in the progress of your projects. There's no need for any paper work moving back and forth. Just import the created nestings and VACAM knows exactly which nests need to be produced.

Our software engineers work daily on smart updates, incorporating user experiences and market developments into new initiatives and innovations. Our recent updates are mainly aimed at increasing process flexibility and improving the interaction between man and machine. With features such as VACAM Scheduling Overview, Scheduler and a real-time Dashboard, you can appoint your operators as managers, since their main task will shift from operating the machine to loading and unloading and managing the entire workshop.

THESE ARE OUR FOCUS AREAS

AND ARE CONSTANTLY SUBJECT TO DEVELOPMENT

CUSTOMER SERVICES

Benefit from our well-known customer service reputation

Our machines are sometimes called indestructible, with only periodic maintenance to act preventively. Yet, when unplanned downtime occurs, we'll be ready for you! We can solve 90% remotely, or make sure a technician is at your location within 24 hours. We do everything in our power to keep your business running.

By choosing one of our three service levels - Red, Grey or White - you get the service we're known for, but with different support options and extra discounts on consumables within each service level.

We go the extra mile when it comes to our high quality machines and solutions, but also with our excellent customer service. International offices and warehouses keep us close and local. With our qualified help-desk team spanning the globe and our support engineers who are pros with hands-on knowledge of Voortman machines, you can rest assured that your machines always run smoothly.