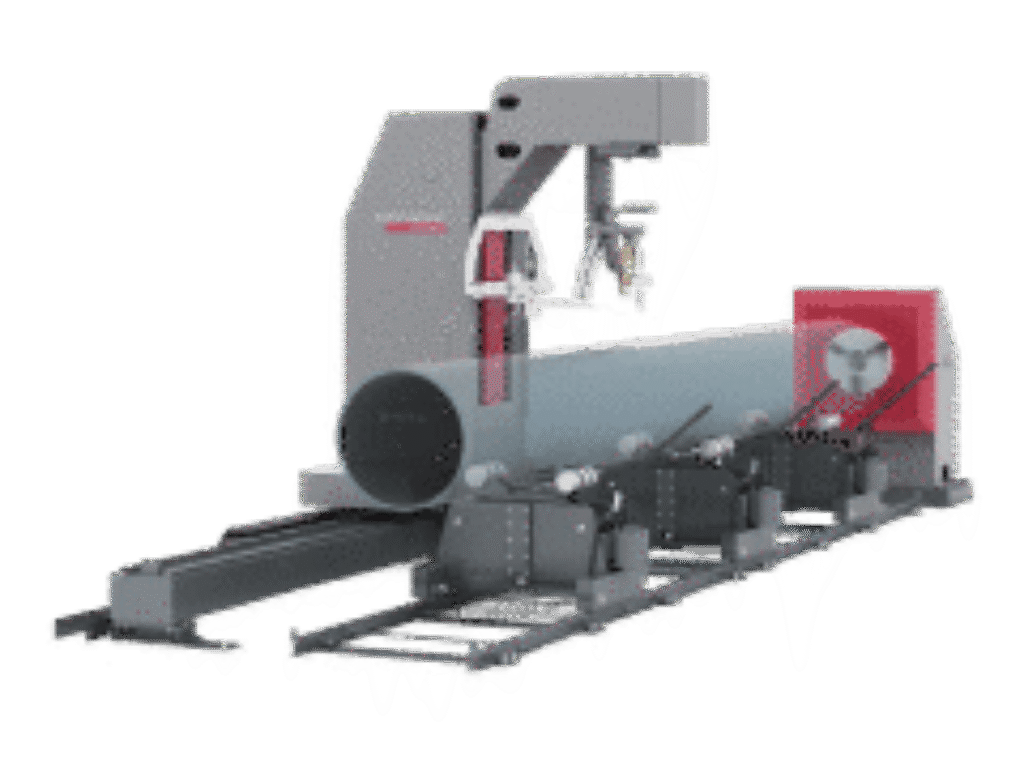

DEMO | MO Compact: Saddle 45°

Watch the Voortman MO Compact deliver high-precision saddle cuts at 45°, combining efficiency and accuracy in a compact, space-saving design. This video highlights the machine’s intuitive operation, robust construction, and flawless cutting performance—making it ideal for high-quality production environments where space and reliability are key.

With 6 CNC axes, the MO Compact ensures clean, repeatable cuts on a wide range of pipe profiles, including angled saddle joints. Its advanced control system simplifies operation, allowing users to achieve consistent results with minimal setup and training. The ability to perform precise 45° saddle cuts makes it especially valuable for applications requiring angled pipe connections and structural integrity. Despite its small footprint, the MO Compact is packed with features that enhance productivity. Its advanced logistical systems streamline pipe handling and reduce downtime, making it perfect for small to medium-sized pipe manufacturers. Industries such as mechanical contracting, shipbuilding, and construction benefit from the machine’s ability to deliver accurate cuts that support strong, reliable assemblies.

The MO Compact stands out for its flexibility, accuracy, and repeatability, all within the smallest footprint among comparable machines. Whether you're cutting saddle joints, concentric slots, or complex geometries, this machine consistently delivers high-quality results. For operations that demand precision cutting in a compact and efficient package, the Voortman MO Compact is the smart choice for modern pipe profile production.

REFERENCES & RESOURCES

Precision and efficiency in a compact design, perfect for small to medium-sized pipe profile cutting with advanced logistical systems.