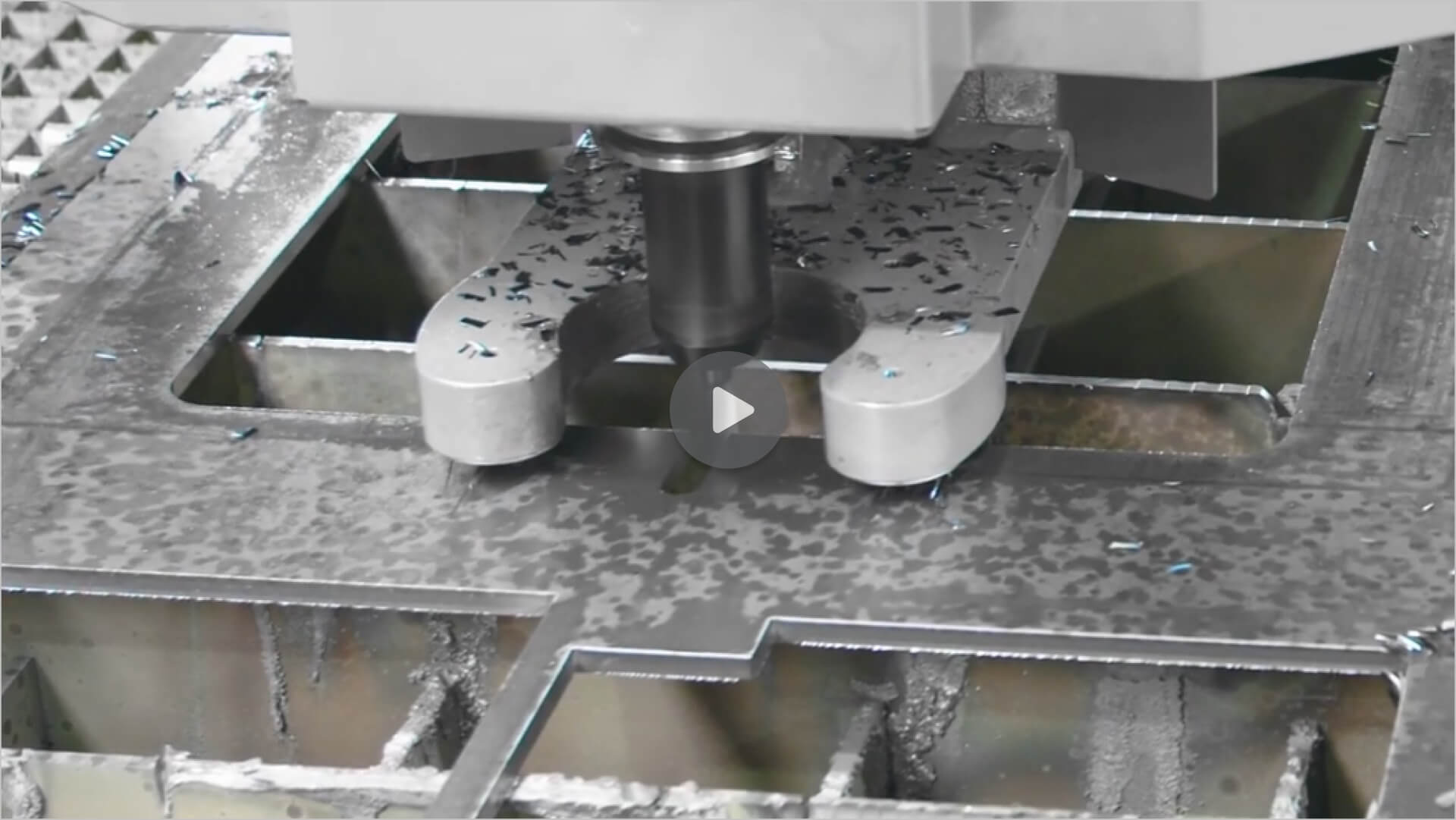

DEMO | V310: Milling

Experience the power and precision of the Voortman V310, the ultimate solution for automated plate milling. This demo showcases the V310’s advanced capabilities, combining intelligent automation with high-speed performance to deliver smooth finishes and consistent accuracy. Designed for fabricators and manufacturers who demand reliable surface machining and edge refinement, the V310 boosts productivity while minimizing manual intervention.

The V310 is a multifunctional CNC plate machine that integrates milling, drilling, tapping, and cutting in a single setup. Its robust gantry design and intelligent tool handling system ensure stable feed rates and low vibration, even during complex milling operations. Automated tool changes and optimized software control allow seamless transitions between processes, resulting in efficient and precise material removal.

Built for heavy-duty performance, the V310’s rigid construction supports demanding milling tasks while extending tool life and maintaining consistent quality. Features such as scheduling and buffering enable fully unmanned operation, and real-time dashboard insights help monitor progress and maximize uptime. This makes the V310 a reliable choice for professionals who prioritize precision, automation, and long-term efficiency.

Hybrid Milling: Smarter Contour Processing

With the new Hybrid Milling functionality, you can create contours with mill-quality results while saving time and costs. The machine intelligently cuts part of the contour first, then mills the remaining section—no process knowledge or manual programming required. The V310 makes smart decisions automatically, simplifying complex tasks.

Milling Without Limits

The V310 gives you complete flexibility to process any product, from small or large slotted holes to intricate shapes with varying milling depths. Local clamping and auto-calculated milling paths allow full control over size, depth, and geometry. Processing entire parts in one station reduces additional costs and eliminates complex factory routing.

Automate Quality with Built-In Intelligence

The V310 is designed to reduce dependency on in-house expertise. With features like Xtensive Bevel Cutting Technology, even complex bevels are cut automatically without manual correction or pre-sample cutting. VACAM software calculates ramping cycles, required tooling, and tool paths automatically. Combined with technologies like Dross Inhibitor, TrueVolt, and Xtensive Hole Technology, the V310 can handle the most complex products with full automation.

Watch the demo to see how the Voortman V310 transforms plate milling into a streamlined, high-efficiency process. For manufacturers seeking precision, flexibility, and intelligent automation, the V310 is the smart choice for modern CNC plate processing.

REFERENCES & RESOURCES