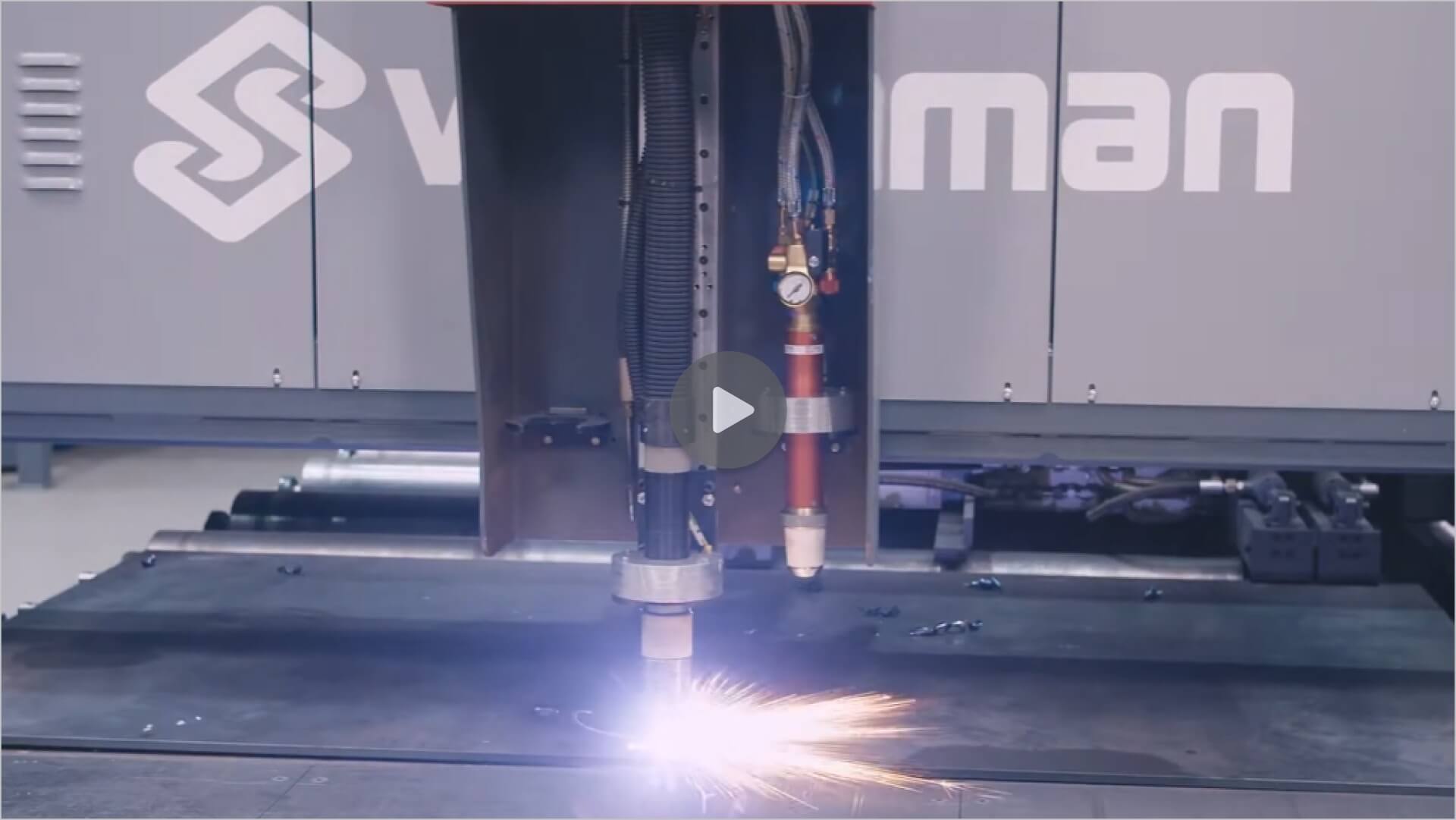

DEMO | V320: Plasma Cutting

Discover How Plasma Cutting Maximizes Efficiency and Reduces Costs. plasma cutting is designed to deliver exceptional precision and productivity while minimizing waste and consumable costs. Advanced features like bridge cutting and intelligent torch technologies ensure faster processing, better material usage, and lower operating expenses.

Bridge Cutting for Maximum Efficiency

Boost your cutting speed and reduce costs with nesting bridge cuts. This technique saves up to 8 seconds per product by discharging an entire row of parts in one go, while reducing the need to turn off the plasma arc. Fewer pierces mean lower consumable wear and improved material utilization—perfect for high-volume operations.

Optimized Torch Technology

Both plasma and oxy-fuel torches share cutting-edge features like fast height control and TrueVolt technology, mounted on identical magnetic systems. This design eliminates calibration, tolerances, and downtime. In case of a collision, operators can quickly remount the torch thanks to the magnetic system, keeping production moving. Switching between plasma and oxy-fuel for different thicknesses is quick and effortless.

How to Improve Your Plasma Consumable Management

Finding the right time to change consumables is critical for cost control and cut quality. In our webinar with Hypertherm, experts shared actionable strategies to optimize consumable life and reduce operating costs. Watch the recording to learn practical tips you can apply immediately to your workflow.

Precision and Reliability

Plasma cutting delivers consistent, high-quality results with advanced CNC control and real-time monitoring. Combined with bridge cutting and smart torch technologies, it ensures efficiency, accuracy, and long-term value for fabricators who demand the best.

REFERENCES & RESOURCES