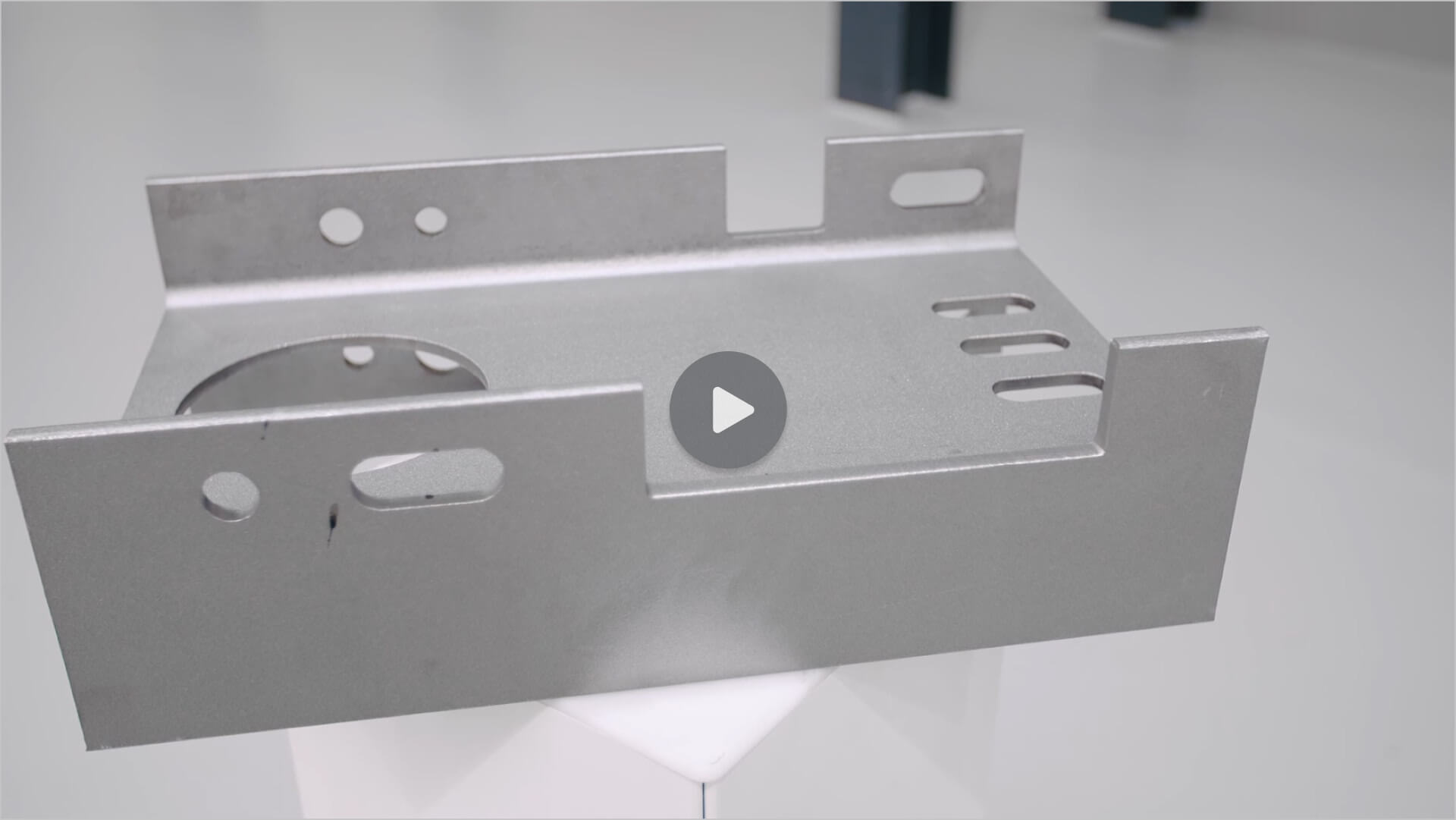

DEMO - V807: Holes & Slots

Experience the precision and efficiency of the Voortman V807, engineered to create holes and slots for bolted connections with complete automation and accuracy. This advanced system ensures compliance with international standards, delivering ready-to-assemble components that minimize rework and speed up production. With its robust design and intuitive controls, the V807 guarantees flawless execution for structural steel joints and complex assemblies.

The V807 is an all-in-one solution that integrates cutting, coping, drilling, milling, and marking into a single streamlined workflow, eliminating the need for multiple setups. Its ability to process all sides of beams, tubes, and custom profiles provides unmatched flexibility for demanding projects. Thanks to VACAM software, manual programming is no longer required—simply import your 3D files and start cutting immediately. Smart material handling and autopilot features enable continuous, unmanned operation, reducing labor costs and maximizing throughput.

What sets the V807 apart is its ability to produce certification-ready holes and slots that meet EN 1090 and AISC standards. Hypertherm True Hole technology ensures superior roundness and edge quality, even on small diameters, reducing the need for secondary operations. By automating these critical processes, the V807 guarantees accurate dimensions and perfect alignment for bolted connections, making assembly faster and more reliable.

Engineered for versatility and ease of use, the Voortman V807 combines cutting-edge technology with operator-friendly controls. For companies seeking precision, adaptability, and efficiency in creating holes and slots for bolted connections, the V807 is the machine that exceeds expectations.

REFERENCES & RESOURCES