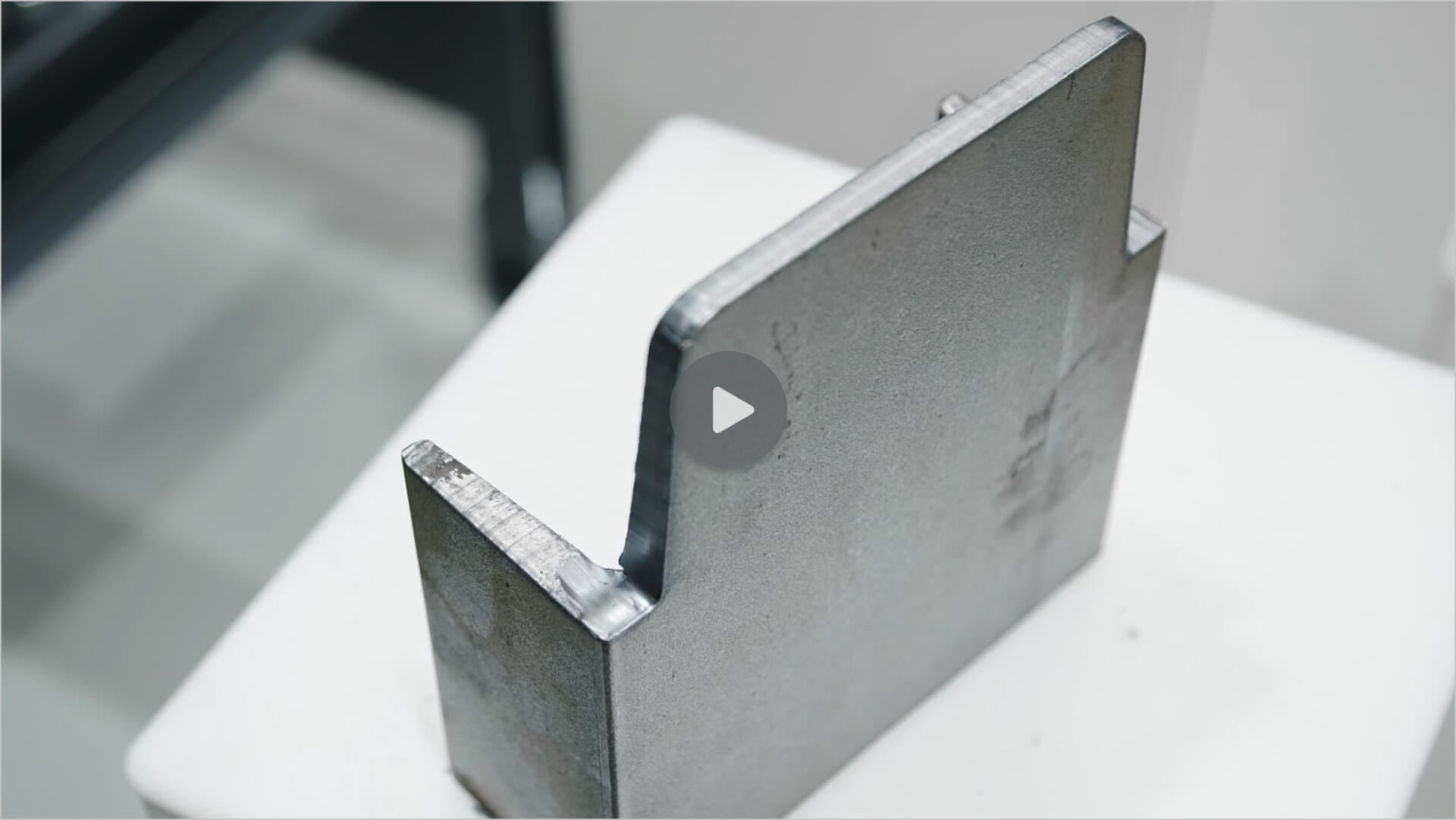

DEMO - V807: Weld Fit Connection

Experience the productivity boost of the Voortman V807, engineered to deliver cutting quality that minimizes post-processing and accelerates throughput. By combining Hypertherm’s industry-leading plasma technology with Voortman’s advanced software optimizations, this system ensures clean, precise cuts that require minimal manual finishing. The result is faster production and ready-to-weld components with just a few simple actions.

The V807 is an all-in-one solution that integrates cutting, coping, drilling, milling, and marking into a single automated workflow, eliminating the need for multiple setups. Its ability to process all sides of beams, tubes, and custom profiles provides unmatched flexibility for complex projects. Thanks to VACAM software, manual programming is no longer required—simply import your 3D files and start cutting immediately. Smart material handling and autopilot features enable continuous, unmanned operation, reducing labor costs and maximizing efficiency.

What sets the V807 apart is its ability to reduce slag to an absolute minimum. With optimized cutting parameters and advanced motion control, slag adheres far less to the material, making cleanup quick and easy. This means your components are ready for welding without time-consuming grinding or chipping, saving hours of labor and improving overall workflow. Combined with blasting post-cut, the process ensures a flawless finish and eliminates the need for skilled workers to handle tedious cleanup tasks.

Engineered for precision and ease of use, the Voortman V807 combines cutting-edge technology with operator-friendly controls. For companies seeking superior cutting quality, reduced post-processing, and maximum productivity, the V807 is the machine that exceeds expectations.

REFERENCES & RESOURCES