THREE-AXIS PROFILE DRILLING AND MILLING

The Voortman V630 drill offers high productivity with its three independently operating drill heads. The proven long-standing track record of this machine speaks for itself.

It is one of the most economical choices to support drilling, milling and marking operations.

It can drill both web and flanges at the same time, reducing labor and operating costs.

Each drill head features an automatic tool changer with six tool positions for various tasks such as drilling, milling, tapping, countersinking, layout marking and centerpoint marking.

MAXIMIZE YOUR OUTPUT

ON A SMALL FOOTPRINT

With its three independent drilling heads, each with an automatic tool changer, the Voortman V630 provides a high level of flexibility and output.

Drilling, milling, marking, tapping, countersinking, 4-sided layout marking and center point marking, the machine does it all, with a high level of automation.

Its versatility ensures that it can handle almost any production task, making it an excellent investment as it will hardly be idle.

UNMATCHED ACCURACY AND QUALITY

YOU'LL BE AMAZED

This machine is designed to produce high-quality output consistently, with features such as precise measuring systems and a robust construction that aid in achieving this objective.

EASE YOUR OPERATOR

MAKE MULTI-TASKING EASY

The built-in process knowledge and automation capabilities of this machine eliminates the need for specialized operator knowledge.

Automated features and user-friendly controls allow operators to attend to other tasks in the workshop while the machine runs independently.

A 24" touch panel displays relevant information and provides suggestions to facilitate a smooth production process.

Integration in your workshop

Combined sawing and drilling with measuring rolls

The fastest measuring and transportation system for profiles in the market

The Voortman roller feed measuring system uses two feeder rolls to the move material. Two measurement wheels are installed to accurately track the profile's position.

Feeder rolls are often used because of the required space and the flexibility when integrated into a larger system.

With a measuring roll system, it is also possible to load a new profile once the first profile has passed the edge of the cross transports.

Since a feeder roll does not have a rail, it is possible to feed into the machine from two sides.

With Voortman, you have a choice in measurement systems, making it possible to tailor the system to the characteristics of your production database.

Combined sawing and drilling with feeder truck

A strong and robust servo driven gripper truck for processing many small products

Voortman also offers a strong and robust servo driven gripper truck. This truck is the fastest truck available, adapting its velocity dynamically to the profile's total weight.

This makes the truck more agile and safe for the operator. The feeder truck holds the material with a wide clamp, which is rotated automatically when the geometry of the profile demands.

This measuring system is capable of moving even the heaviest profiles without losing its stability.

The gripper truck can be combined with the VB beam sawing machine - often with an automatic Short Product Removal System (SPRS) where the gripper clamps all products up to 1.400 mm (4-1/2') during cutting, and then short products are transported sideways.

With the SPRS and the gripper truck, the drill and saw become fully autonomous with clean cuts automatically dropped into a separate bin.

Just start your latest production run before you close the factory for the night and arrive in the morning with all products processed and sorted on the outfeed cross transports.

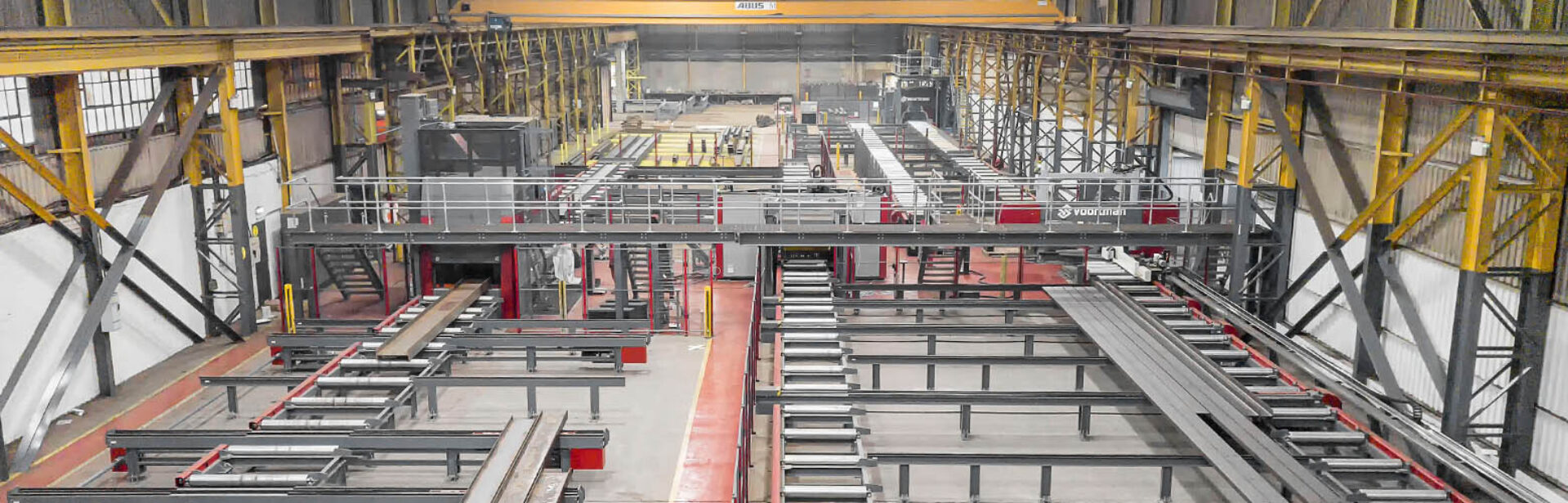

Full automation in a modular split system

Reduce labor costs and increase efficiency

MSI, also referred to as Multi System Integration, opens the door to fully automate your production by connecting machines with cross transports, roller conveyors, product buffers, and material sensors.

Production data only needs to be imported once and then MSI automatically distributes the data to all machines integrated in your production system.

VACAM decides optimal material route

Based on the production on hand, customer preferences and the available machinery in the MSI-line, VACAM automatically decides the optimal route to reach the highest efficiency.

MSI designates the end of transporting raw profiles and semi-finished products from machine to machine. MSI stands for one integrated production system.

You can track and monitor every profile, product and future planning in real time by using VACAM, Voortman’s proprietary CNC control software installed on every machine.

Designing your optimal layout

Together with you, the Voortman team designs the entire layout based on your current or expected production characteristics, such as type of profiles, product length, number of processes, hours in your work week and budget.

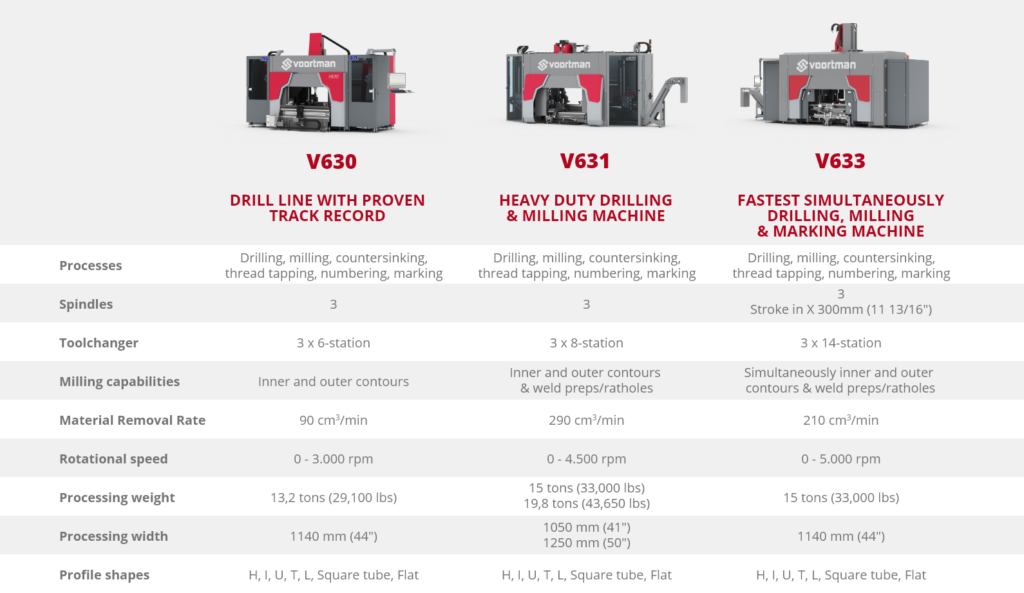

DIFFERENT SPECS FOR DIFFERENT NEEDS

Find which suits you best!

At Voortman, we offer a versatile range of machines in our beam drilling portfolio, each with unique specifications to cater to different production needs.

Take the time to explore your options and find a machine that perfectly suits your goals.

Contact us to learn more and let our team of experts assist you every step of the way.

Specifications

| Voortman V630 | ||

|---|---|---|

| Voortman V630 | ||

| Operating range | inch | 25/64 x 2 1/3 – 17 3/4 x 44 |

| Positioning weight | lbs | 29,100 |

| Drilling and positioning | Servo motors | |

| Positioning speed X | f/min | 138 |

| Positioning speed Y | f/min | 98 |

| Positioning speed Z | f/min | 98 |

| Drilling units | 3 | |

| Nominal power | Hp | 40 |

| Speed | rpm (stepless) | 0 - 3.000 |

| Tool changer | 3 x 6 | |

| Drill holder | SK40 | |

| Drill diameter | inch | 13/64 - 1-9/16 |

| Thread tapping | M6 - M30 | |

| Machine weight | lbs | 24,250 |