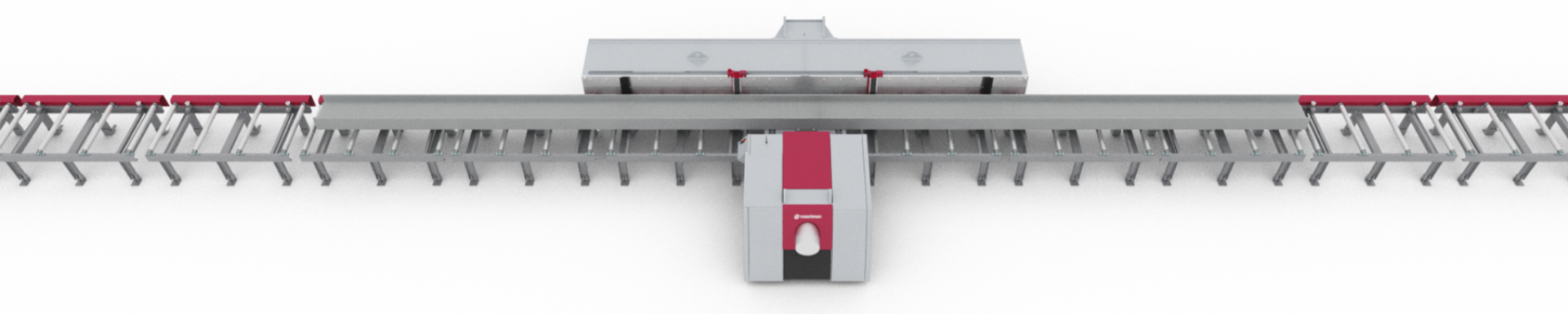

Voortman V2000

Beam cambering

The Voortman V2000 CNC beam cambering and straightening machine boasts a rigid steel C-frame, horizontal cylinder pusher and memory settings for a repeatable, reliable output every time. A user-friendly touchscreen operator panel makes operating the V2000 easy with a short learning curve for operators.

Efficient profile cambering / straightening

REPEATABLE MEMORY POSITIONS

The V2000 has two moveable reaction points that include an electric switch to indicate both points are touching the material. The PLC control can save the data to repeat the same camber on subsequent profiles, significantly speeding up processing times. The reaction point position can be easily adjusted by releasing a handle and doesn’t require screwing/unscrewing to move.

MONITOR RESULTS IN REAL TIME

The V2000 integrated PLC system has a touch panel to indicate the current machine status and give full insight to the cambering process. By determining the zero-reference and saving the neutral and work stroke, the PLC is able to make a fully automatic stroke. The combination of automation and feedback gives you a clear look in on the process with minimal manual operation intervention required.

High quality profiles

ACCURACY AND QUALITY

The V2000 has an integrated measurement system that determines the cambered depth. It automatically corrects when the cambered depth isn’t met, significantly increasing the accuracy of cambering and processing quality.

Integration into a complete MSI layout

The V2000 is often used as a standalone machine, however, with roller conveyors and cross transports the V2000 can easily be integrated into a Multi System Integration (MSI) layout. This makes handling profiles and products easy and efficient.

Specifications

| Voortman V2000 | |||

|---|---|---|---|

| V2000-200 | V2000-400 | ||

| Operating range | inch | 2 - 33-1/2 | 2 - 41-1/2 |

| Capacity | tons | 220 | 440 |

| Hydraulic motor | Hp | 25 | 50 |

| Profile | HEB800 | HEM1000 | |

| UB | 914 x 305 x 253 | 914 x 419 x 343 | |

| W | 36 x 12 x 160 | 40 x 12 x 235 | |

| Reaction beam | feet | 26-1/4 | 26-1/4 |

| Weight base frame | lbs | 16,500 | 23,150 |

| Weight reaction beam | lbs | 16,500 | 26,450 |

| Working height | inch | 33-1/3 | 33-1/3 |