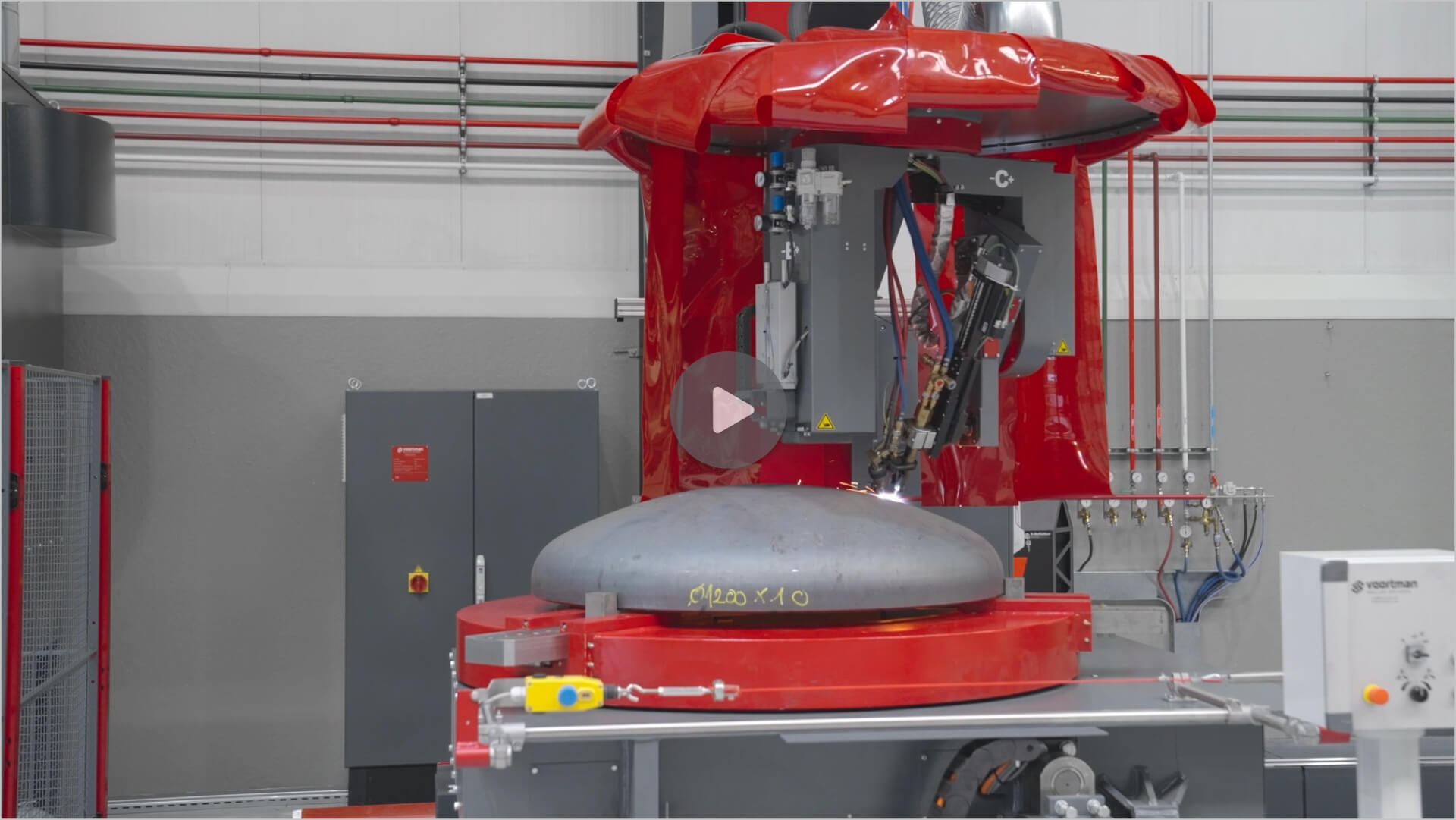

DEMO | MO Classic: Dome Cutting

Experience the cutting-edge performance of the Voortman MO Classic, engineered for precision dome cutting in demanding industrial environments. This video highlights the machine’s robust design, intuitive user interface, and exceptional cutting accuracy; making it the ideal solution for high-quality production where reliability and space efficiency are essential.

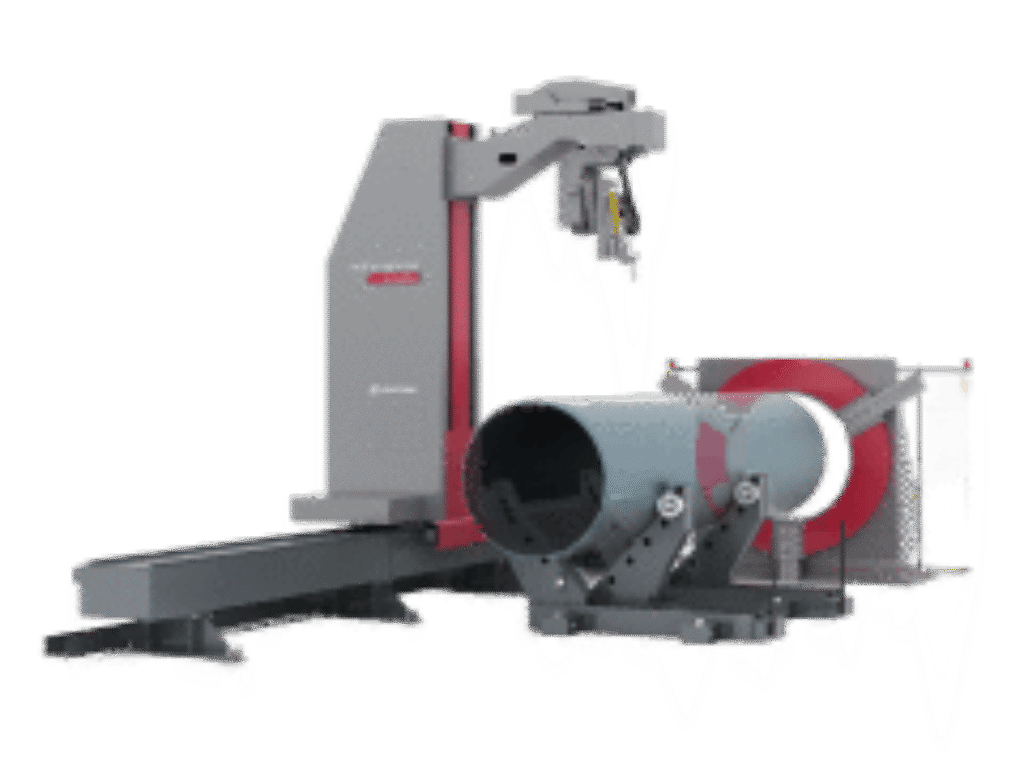

The MO Classic is equipped with 6 CNC axes, enabling clean and accurate cuts on complex dome shapes and pipe profiles. Its advanced Laser Measuring System automatically compensates for pipe ovalities, banana shapes, welding seams, and dome geometries, ensuring flawless results even with irregular materials. This makes it a powerful tool for industries such as oil and gas, shipbuilding, process engineering, and heavy machinery manufacturing. What sets the MO Classic apart is its unique chuck design and advanced logistical capabilities, which allow for seamless handling of various pipe sizes and dished-ends. Whether you're cutting domes for pressure vessels or intricate pipe connections, the MO Classic delivers consistent, high-quality output with minimal setup time.

Designed for versatility and ease of use, the MO Classic combines high-end technology with operator-friendly controls, making it a preferred choice for companies seeking precision, adaptability, and efficiency in dome cutting operations. If your production demands clean, reliable, and space-efficient dome cutting, the Voortman MO Classic is the machine that meets and exceeds expectations.

REFERENCES & RESOURCES

The most versatile pipe profile cutting solution, equipped with advanced logistics and a unique chuck design for diverse industrial applications.