MO CLASSIC

PIPE PROFILE CUTTING MACHINE

The most versatile pipe profile cutting solution, featuring advanced logistics and a uniquely engineered chuck design; ideal for a wide range of industrial applications.

- 6 CNC Axis for high precision and clean cuts

- Laser measuring system for compensating pipe ovalities, banana-shaped deviations, welding seams, and dome cutting

- Advanced logistical options

Available models:

ø1200 | ø1500 | ø2000

Compatible with software solutions:

Corobs | PypeServer

OVERVIEW

The Voortman MO Classic is the most versatile machine in the VMO lineup, catering to a wide range of industries including oil and gas, steel processing industry, shipbuilding, and heavy machinery manufacturing. With the addition of advanced logistical systems, this machine is perfect for companies that need to cut various pipe shapes and sizes, as well as dished-ends. Its adaptability and high-quality output make it a preferred choice for complex and diverse pipe profile cutting requirements.

MACHINES IN THIS PRODUCT LINE

SUCCESS STORIES

We deeply value our customers and their feedback; it's what drives us to keep improving and innovating. Curious how our machines make a difference? Hear directly from our customers as they share their experiences.

APPLICATIONS

FEATURES

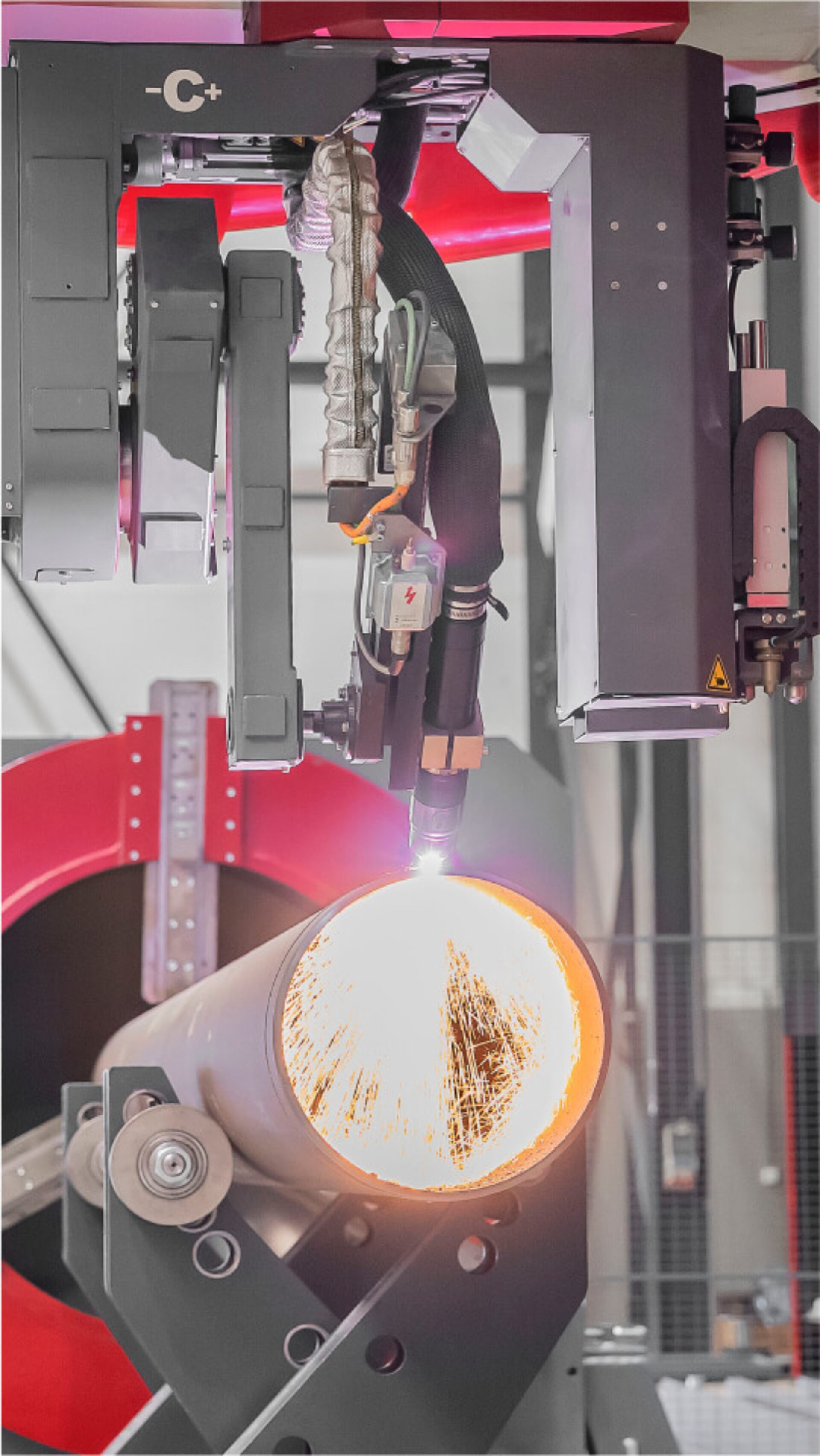

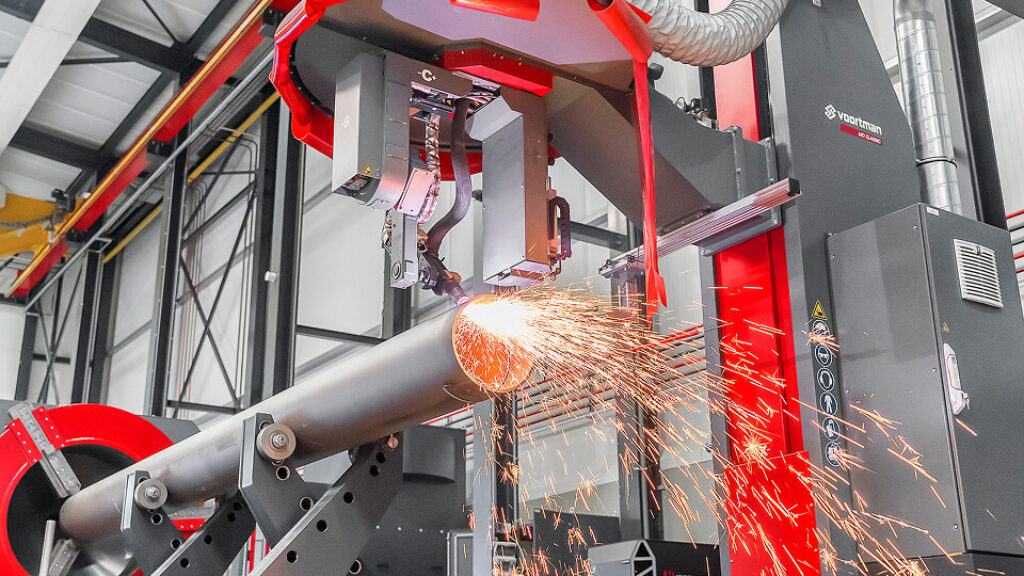

6 CNC AXES WITH W-AXIS RETRACTION

Delivers precise, clean cuts, even around welding seams, thanks to the advanced W-axis that retracts the torch when reaching the welding seam.

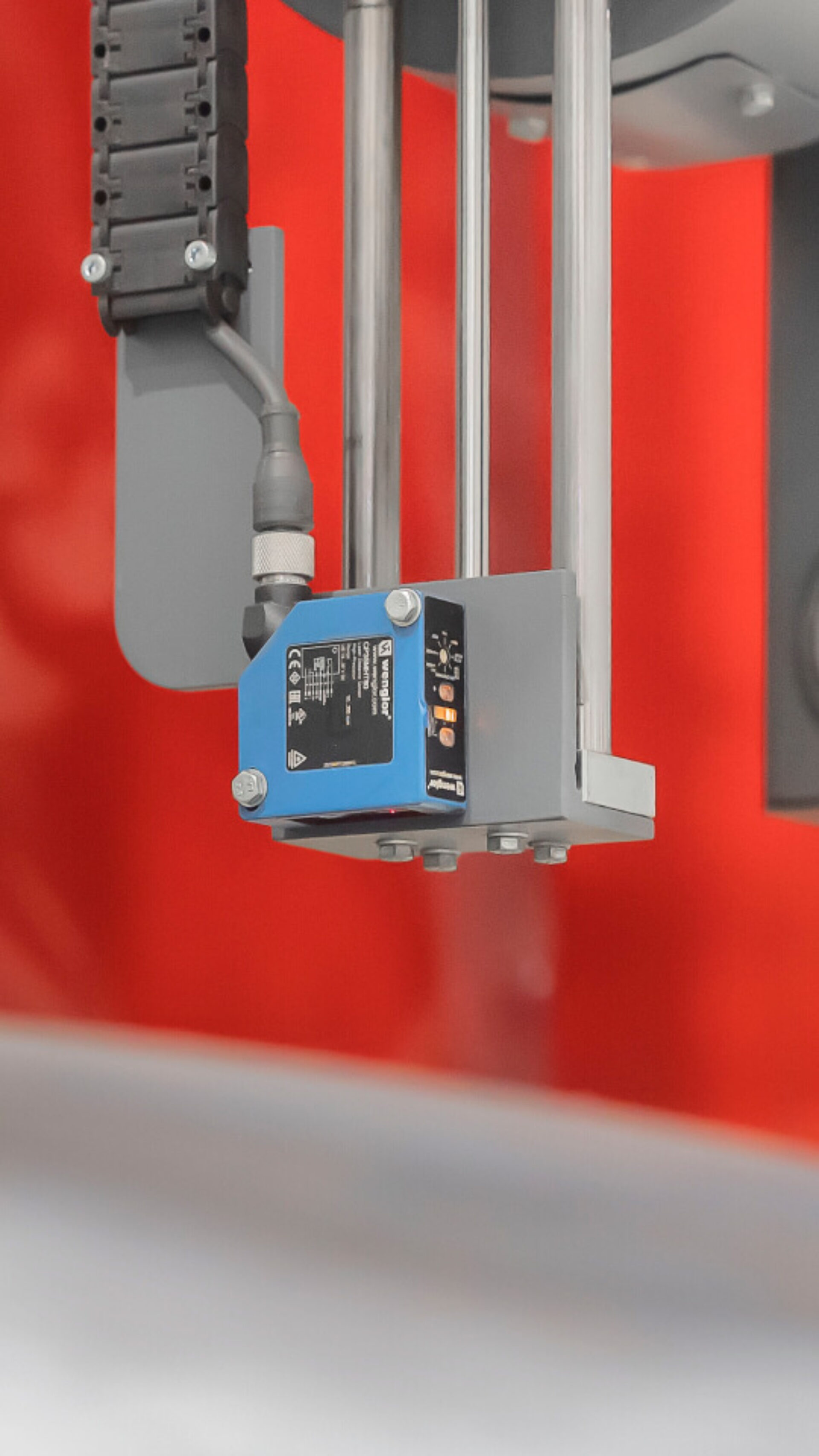

LASER MEASURING SYSTEM

Laser sensor system for maintaining constant torch-to-pipe clearance. Before cutting, the sensor performs a high-speed dry run to dynamically scan and measure pipe surface positions, ensuring precise torch control.UP TO 70 DEGREES CUTTING HEAD

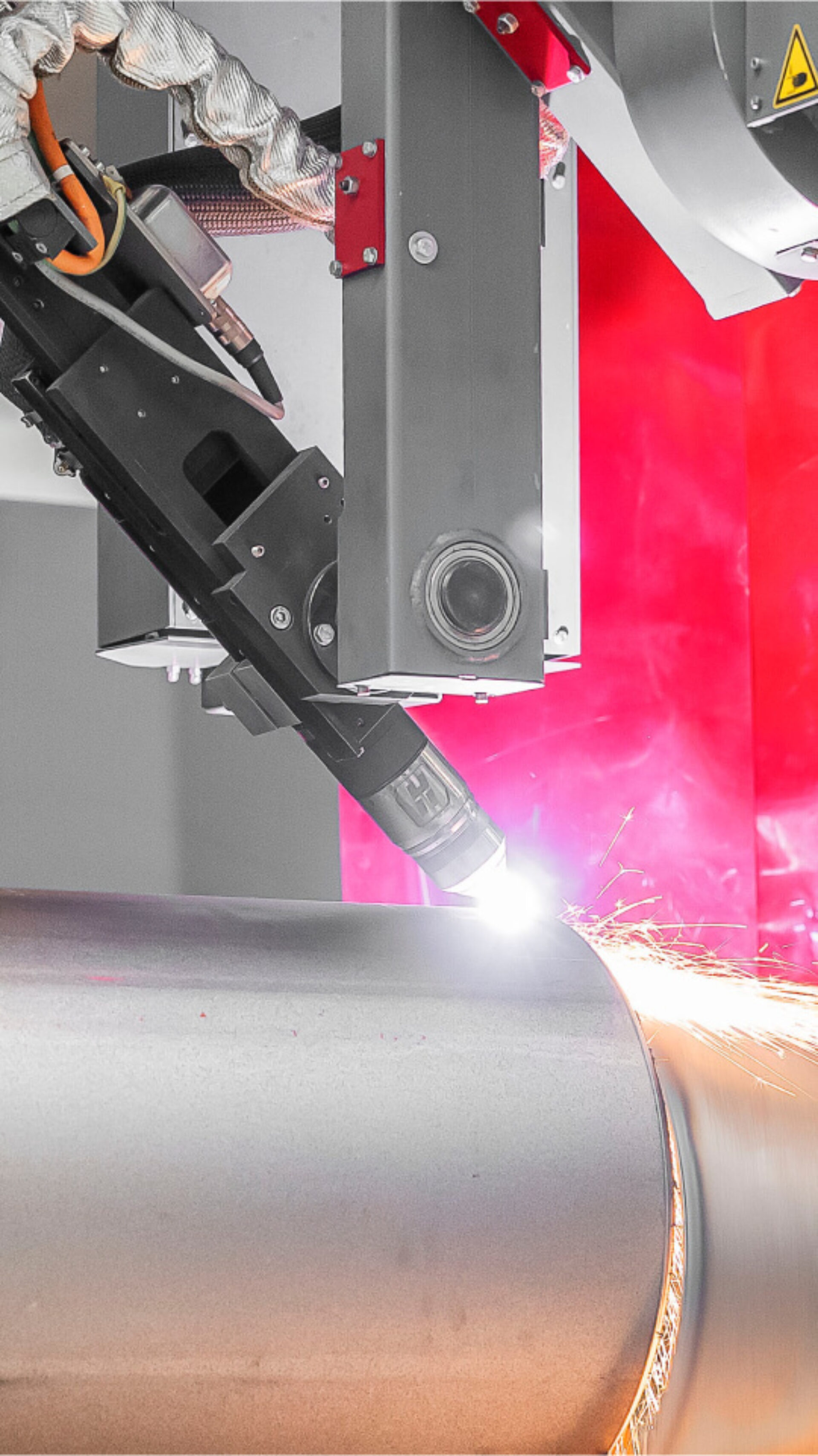

Torch inclination of up to 70°, supported by advanced software, enables the creation of complex cutting shapes with weld bevels that transition smoothly from the outer to the inner surface of the pipe.

BENEFITS

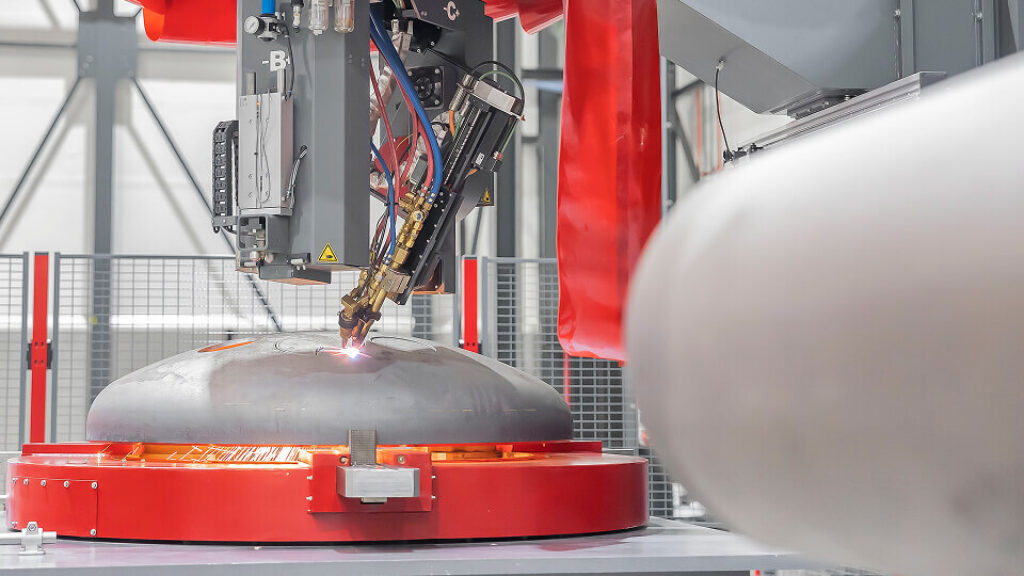

DOME CUTTING

Capable of handling dished-ends (dome cutting) next to round pipe cutting.

COROBS

Most sophisticated software in the market for generating the required cutting shapes with various weld bevels.

DURABLE CONSTRUCTION

Built with high-quality materials to withstand rigorous industrial use, ensuring long-term reliability.

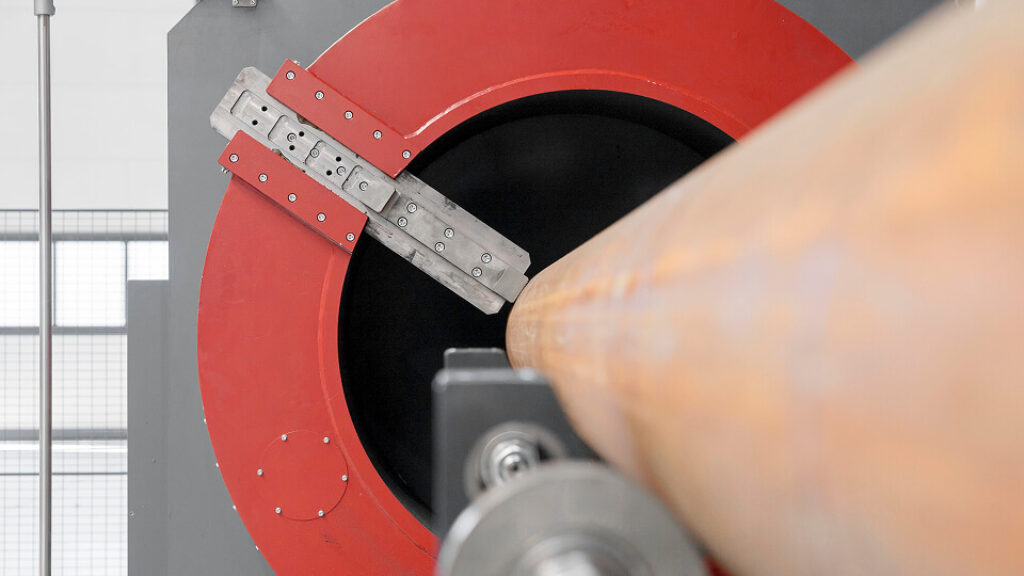

CUTTING BEHIND THE CHUCK

Through-push possibility in the chuck to enable cutting in front of and behind the chuck. A single setup for higher productivity.

SPECIFICATIONS

1200

Min/Max Clamping

48 - 1.220 mm (1.9x48")

Max Workpiece Weight

12.000 kg

Installation Surface

9.000 x 5.000 x 3.500 mm (29.5x16.4x11.5ft)

1500

Min/Max Clamping

80 - 1.524 mm (3.2x60")

Max Workpiece Weight

15.000 kg

Installation Surface

9.000 x 5.000 x 4.200 mm (29.5x16.4x13.8ft)

2000

Min/Max Clamping

80 - 2.032 mm (3.2x80")

Max Workpiece Weight

20.000 kg

Installation Surface

9.000 x 5.000 x 4.200 mm (29.5x16.4x13.8ft)

UPGRADE YOUR MACHINE

Advanced Logistics

Logistical assemblies such as loading rack, infeed conveyor, cutting conveyor, kick-off mechanism, off-loading rack, with freely selectable composition to reduce loading and unloading times in the machine for approximately 30% increase in productivity.

Industry-Specific Macro Packs (COMING SOON)

Choose from tailored macro sets designed for specific industries, with the flexibility to upgrade or expand as your needs evolve.

Dual Cutting Technology

Equip your machine with both plasma and oxy-fuel cutting capabilities for maximum versatility in material processing.

PypeServer Enterprise

The MO series comes standard with CorObs for on‑machine programming. You can add PypeServer Enterprise to import CAD files directly, automate features like saddles and O‑lets, and optimize material usage with advanced, defect‑aware nesting. PypeServer Enterprise also reports real‑time production updates to PypeServer Cloud, improving tracking and coordination.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

The Voortman MO pipe cutting machines support both plasma and oxy-fuel cutting. Plasma is ideal for thin to medium wall thicknesses with high speed and precision, while oxy-fuel is better suited for very thick wall pipes. In addition, oxy-fuel can cut at steeper angles than plasma, providing more flexibility for complex weld preparations. This ensures the right technology is available for each material and project.

Depending on the machine model, pipe diameters from 50 mm up to 4.000 mm can be processed. Lengths of up to 18 meters are supported. Plasma typically handles wall thicknesses up to 50 mm, while oxy-fuel can cut much thicker pipes. It’s important to note that the angle of the cut affects the effective cutting length, so wall thickness alone does not determine cutting time or capability, steeper bevels result in longer cuts. All common materials including carbon steel and stainless steel can be cut. These are widely used in offshore, shipbuilding, and construction all over the world.

The Voortman MO pipe cutting machines can produce a variety of holes, bevels, miters, saddles, dome cuts, and branch connections. The multi-axis torch motion allows for precise 3D profiles, ensuring pipes are ready for welding or assembly without extra manual work.

Bevel cutting is essential for welding preparation. It creates the correct edge angle and shape on the pipe end, ensuring strong, clean welds and reducing the need for additional grinding or manual preparation.

Yes, the Voortman MO pipe cutting machines are fully CNC-controlled and cutting programs are generated with our COROBS CAD/CAM software. COROBS optimizes cutting paths, automates torch movements, and minimizes operator input, making production faster and more consistent.

The Voortman MO pipe cutting machines provide a higher accuracy, repeatability, and productivity compared to manual methods. Complex geometries can be cut in a single setup, reducing material waste, saving time, and delivering consistent quality across all parts.