DEMO | MO Classic: Pipe to Dome

Experience the precision of the MO Classic in the pipe-to-dome cutting process. This video showcases the machine’s robust design, user-friendly controls, and exceptional speed and accuracy in transforming pipes into domes; making it ideal for high-quality production environments where reliability and space efficiency are essential.

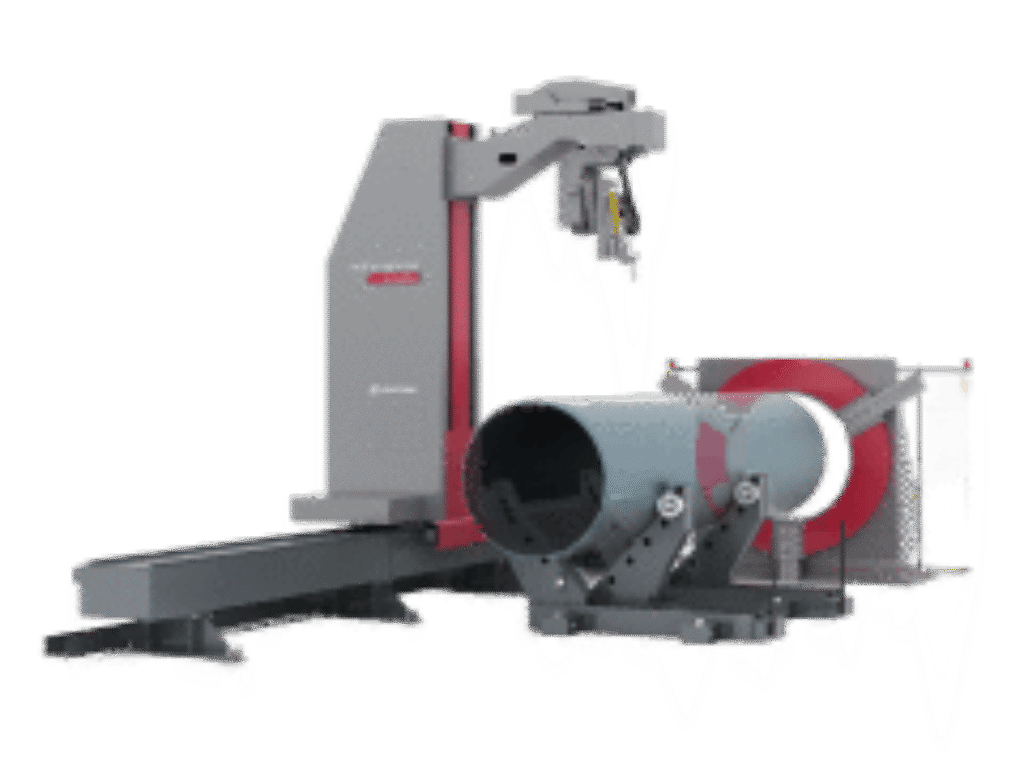

The MO Classic is the most versatile pipe profile cutting solution in the Voortman VMO lineup. It features a uniquely engineered chuck design and advanced logistics, enabling seamless handling of various pipe shapes, sizes, and dished-ends. This adaptability makes it a preferred choice across industries such as oil and gas, shipbuilding, steel processing, and heavy machinery manufacturing. Equipped with 6 CNC axes, the MO Classic delivers high-precision cuts with clean edges, even in complex geometries. Its laser measuring system compensates for pipe ovalities, banana-shaped deviations, welding seams, and dome contours, ensuring consistent and accurate results throughout the cutting process.

Despite its powerful capabilities, the MO Classic maintains a compact footprint, allowing for efficient use of space in production facilities. Its intuitive interface simplifies operation, enabling quick setup and adjustments, which helps reduce downtime and boost productivity. Whether you're processing standard pipes or tackling intricate dome transitions, the MO Classic offers unmatched versatility, precision, and reliability. Watch the video to see how this cutting-edge machine elevates pipe-to-dome processing to a new level of efficiency and quality.

REFERENCES & RESOURCES

The most versatile pipe profile cutting solution, equipped with advanced logistics and a unique chuck design for diverse industrial applications.