CARL HAMM - Up to 30% faster pipeline construction with Voortman MO

“We already had a CNC-controlled pipe cutting machine from another manufacturer, but it was very old and we couldn’t get spare parts anymore. This new machine is state-of-the-art, fully digital, and meets all our requirements, so the decision to switch was relatively easy.”

Mario Schumacher

Production Manager, Carl Hamm

Inspired by this testimonial?

REFERENCED PRODUCTS

THE CHALLENGE

Before working with Voortman, Carl Hamm used an older CNC-controlled pipe cutting machine from another manufacturer. However, the aging machine lacked digital connectivity, and spare parts were no longer available. This created downtime risks and limited flexibility in production. “Our old machine was very analog, and not being able to get spare parts anymore was simply unacceptable,” says Mario Schumacher, Production Manager at Carl Hamm.

ABOUT THE COMPANY

Carl Hamm GmbH, founded in 1929 and based in Essen, Germany, is a specialist in pipeline construction and process equipment. With around 110 employees and an additional location in South Africa, the company is known for high-quality welding and pressure systems, serving demanding projects worldwide with precision and reliability.

CLEAR FROM THE START

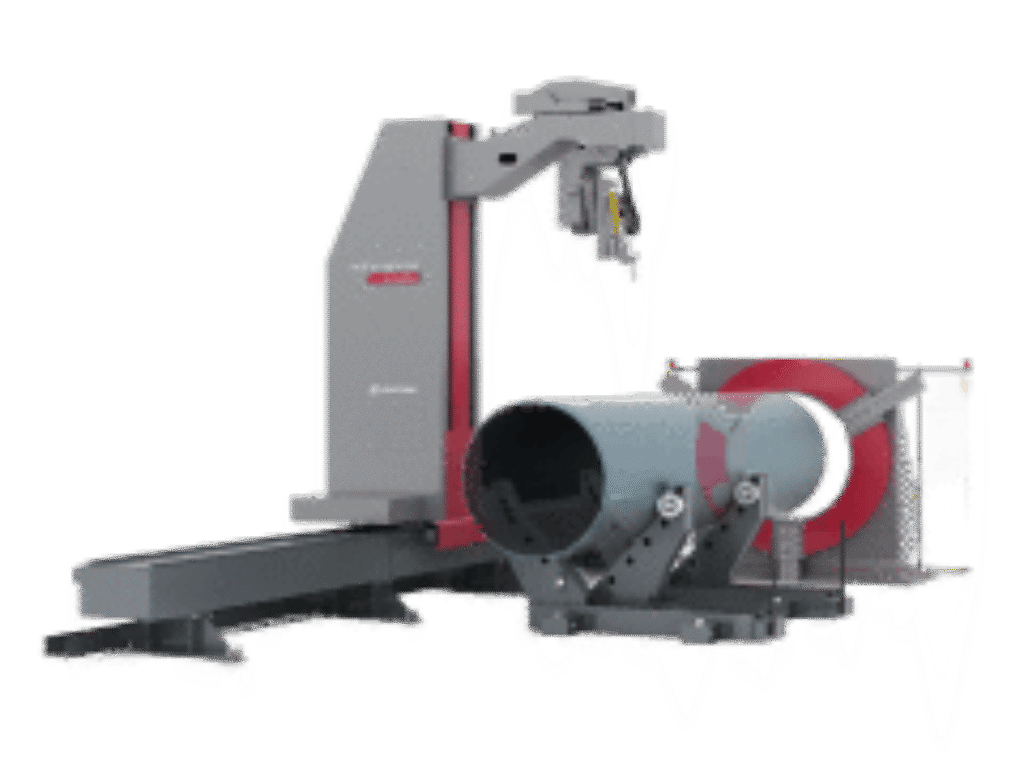

Carl Hamm was already familiar with Voortman through their existing plate cutting machine and knew Voortman as a reliable and proven partner in the plate processing industry. After detailed discussions and seeing the potential, they chose the Voortman MO Classic 1000/1500. The deciding factors were the easy integration with their design processes and the ability to pre-load programs directly from engineering. “It was clear from the start that Voortman offered the right combination of precision, support, and automation,” Schumacher explains.

Carl Hamm has been operating the new Voortman machine for about three months. The implementation went smoothly, supported by a three-day training program that helped their team quickly get comfortable. The new system allows designs to be sent straight to the machine, reducing manual steps and minimizing errors. Operators quickly got used to the intuitive controls and appreciated the time savings. The machine is able to handle about 98% of their production needs. It also allows easy loading and automatically sets heights for quick diameter changes, reducing downtime and making exchanges faster and more efficient.

“We’re ahead of the competition now. Our quality is higher, and our production is faster and more flexible. With Voortman, we’re ready for the future.”

Mario Schumacher

Production Manager, Carl Hamm

STRONGER RESULTS AND A CONFIDENT FUTURE

Since introducing the new machine, Carl Hamm has already seen significant improvements. They estimate a 15–20% overall reduction in production time and even up to 30% time savings before welding. The high-precision cuts and laser measurement ensure perfect fits, even for oval pipes. This results in better-fitting parts and fewer adjustments during welding. Thanks to precise bevel cutting, more products are ready to weld with minimal rework. Additionally, the ability to handle different pipe diameters and leave support webs in place has further increased quality and flexibility.

Looking ahead, Carl Hamm feels well prepared for future challenges, including expanding in international markets and new technologies like hydrogen applications. The partnership with Voortman, marked by direct and reliable communication, has been a key factor. “The biggest advantage for us is having fixed contacts at Voortman who really know our needs. We feel very well supported,” Schumacher emphasizes.

MORE TESTIMONIALS