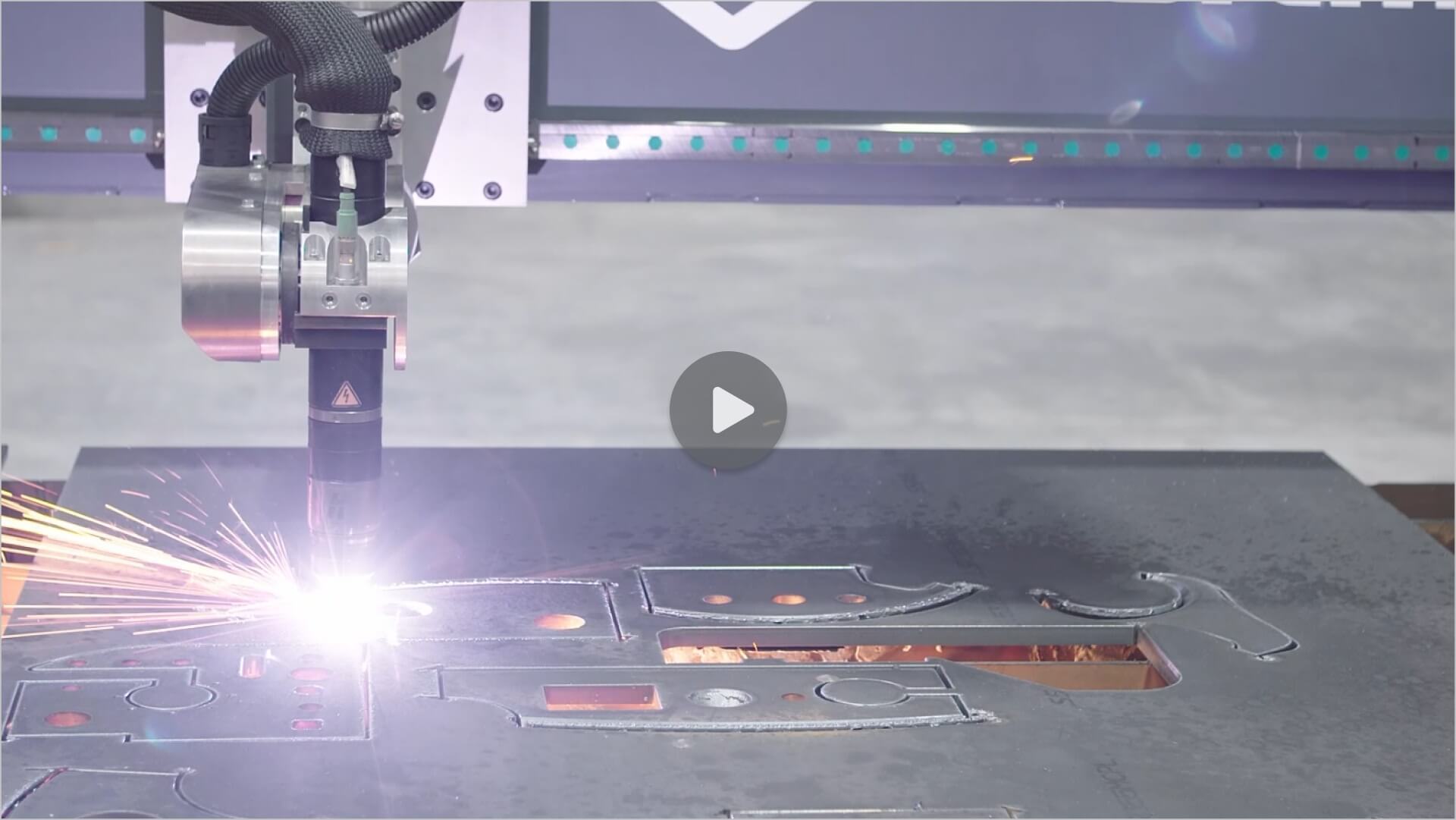

DEMO | V310: Plasma Cutting

Experience the power and precision of the Voortman V310, the ultimate CNC plate processing machine. This demo showcases the V310’s unmatched versatility, combining advanced automation with high-speed plasma cutting, carbide drilling, milling, and thread tapping. Built for fabricators and manufacturers who require full-spectrum plate processing, the V310 delivers exceptional performance, uptime, and long-term reliability.

The V310 integrates oxy-fuel and plasma cutting with high-speed drilling, tapping, milling, and 3D bevel cutting—all in one setup. It processes plates up to 200 mm thick and handles holes from 5 to 50 mm, with thread tapping up to M30. With a dual tool changer system offering up to 28 tools—8 on the gantry for rapid swaps and 20 stationary for extended capacity—the V310 provides maximum flexibility and fully automated tool exchange.

Plasma Cutting Advantages

Plasma cutting is significantly faster than oxy-fuel in the lower mild steel thickness range (3 mm to 25 mm). It offers a cost-effective alternative to high-powered fiber lasers, with up to 75 percent lower capital expenditure while maintaining or exceeding cutting speeds at medium thicknesses (12 mm and above). For medium-to-thick stainless steel, where oxy-fuel is not suitable, plasma is the preferred technology.

High-Quality Restarts

Interruptions during cutting can lead to costly errors and lost parts. The V310’s extended restart functionality minimizes damage by automatically creating an arc-lead, allowing the plasma arc to resume its path with minimal impact. This reduces downtime and preserves product quality without manual corrections.

Magnetic Mounting System

Both plasma and oxy-fuel torches use the same magnetic mounting, benefiting from technologies like fast height control and TrueVolt. This system requires no calibration and is unaffected by tolerances. In the event of a collision, the torch can be quickly remounted, minimizing downtime. Switching between cutting thicknesses is fast and simple by exchanging the torch.

Reduced Cut-to-Cut Time

With Instant Cut Technology, the V310 significantly reduces cut-to-cut time. Initial height sensing is minimized, plasma pre-gas is initiated during movement, and torch retraction height is kept low. These features combine to dramatically increase production speed, especially when processing small parts and holes.

Watch the demo to see how the Voortman V310 transforms plasma cutting and plate processing into a streamlined, high-performance operation. For professionals in steel fabrication, shipbuilding, and heavy manufacturing, the V310 is the smart choice for precision, automation, and scalable production.

REFERENCES & RESOURCES