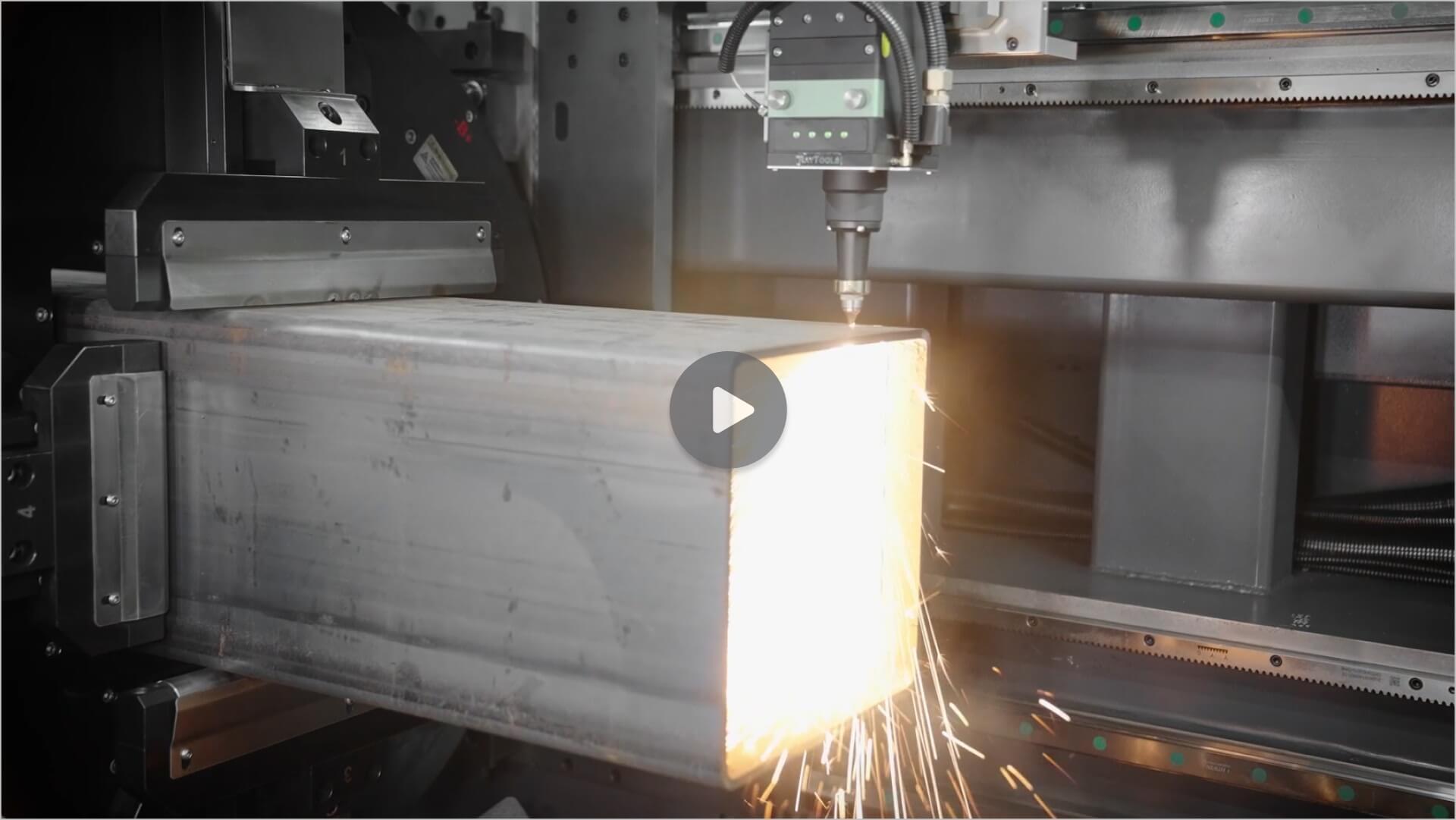

DEMO | V845: Large Tube Cutting

Experience the full capabilities of the Voortman V845, a complete solution for automated 3D laser cutting of large-diameter tubes. Designed for high-performance fabrication, the V845 combines advanced fiber laser technology with intelligent automation to deliver weld-ready results, minimal material waste, and exceptional accuracy, even on oversized and heavy-walled tubing.

This robust machine integrates backside cutting, beveling, and precision profiling in a single setup. It streamlines your workflow and reduces the need for post-processing. The unique three-chuck system allows full rotation and repositioning of tubes, enabling zero tailing and optimal use of every length, even with tubes weighing up to 2.4 tons.

With ±0.1 mm cutting precision, automatic centering, and support for bevel cuts up to 45 degrees, the V845 ensures clean and consistent edges that are ready for welding. Features such as intuitive CNC control, real-time monitoring, and a fully enclosed Laser Class 1 design make it ideal for safe and unmanned operation in demanding production environments. Watch the demo to see how the Voortman V845 transforms large tube cutting into a fast, precise, and highly efficient process. It is trusted by fabricators who value automation, reliability, and top-tier performance.

REFERENCES & RESOURCES