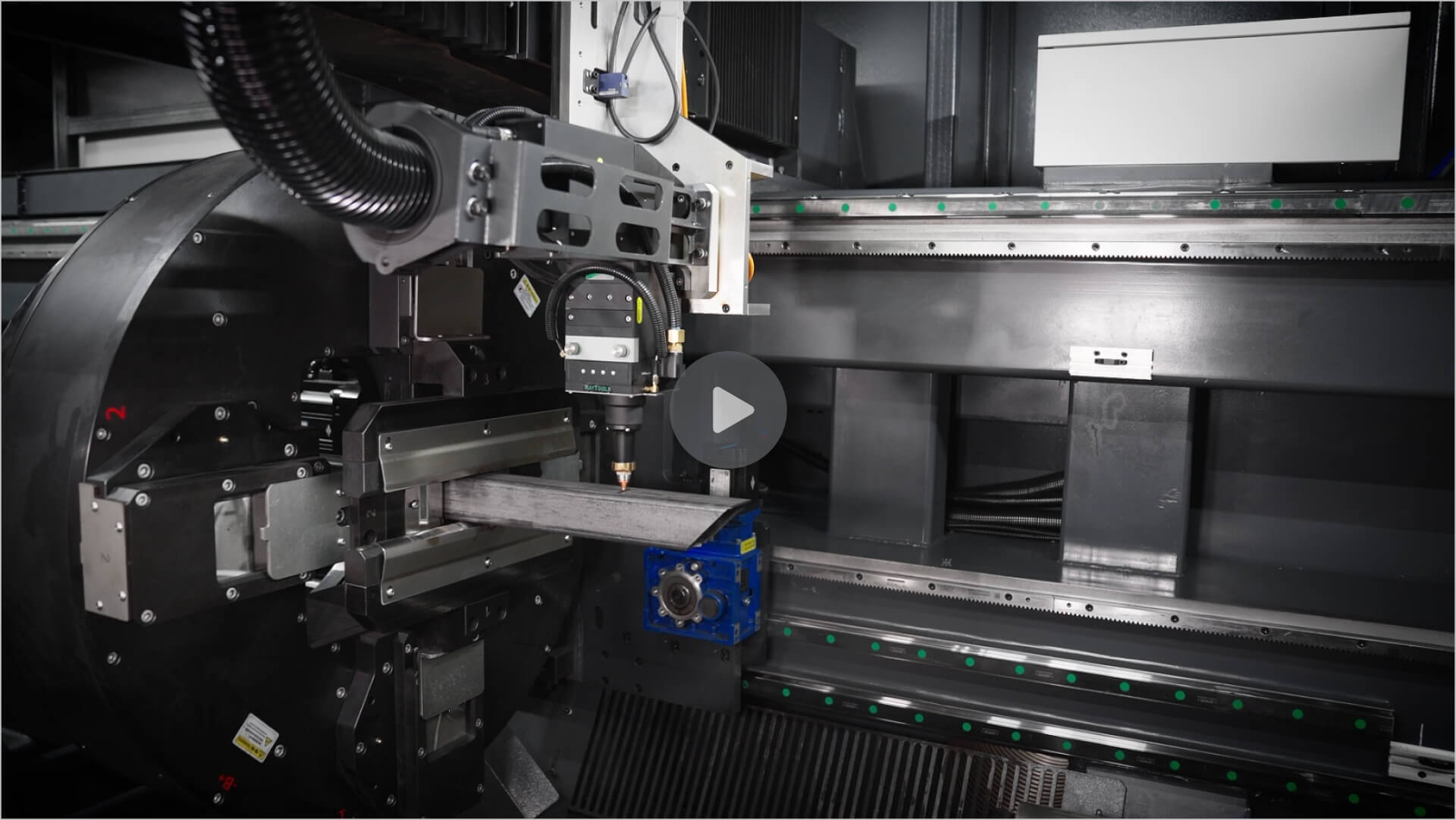

DEMO | V845: Small Tube Cutting

Explore the advanced capabilities of the Voortman V845, a complete solution for automated 3D laser cutting of small-diameter tubes. Built for precision and efficiency, the V845 uses high-speed fiber laser technology and intelligent automation to deliver weld-ready results, reduce material waste, and maintain exceptional accuracy across a wide range of tube sizes.

The machine combines backside cutting, beveling, and precision profiling in one setup, helping you streamline production and minimize post-processing. Its innovative three-chuck system allows full rotation and repositioning of tubes, ensuring zero tailing and optimal material usage, even with heavier tube sections.

With cutting accuracy of ±0.1 mm, automatic centering, and support for bevel cuts up to 45 degrees, the V845 produces clean and consistent edges that are ready for welding. Features such as intuitive CNC control, real-time monitoring, and a fully enclosed Laser Class 1 design make it ideal for safe and unmanned operation in demanding environments. Watch the demo to see how the Voortman V845 turns small tube cutting into a fast, precise, and highly efficient process. It is trusted by fabricators who value automation, reliability, and consistent performance.

REFERENCES & RESOURCES