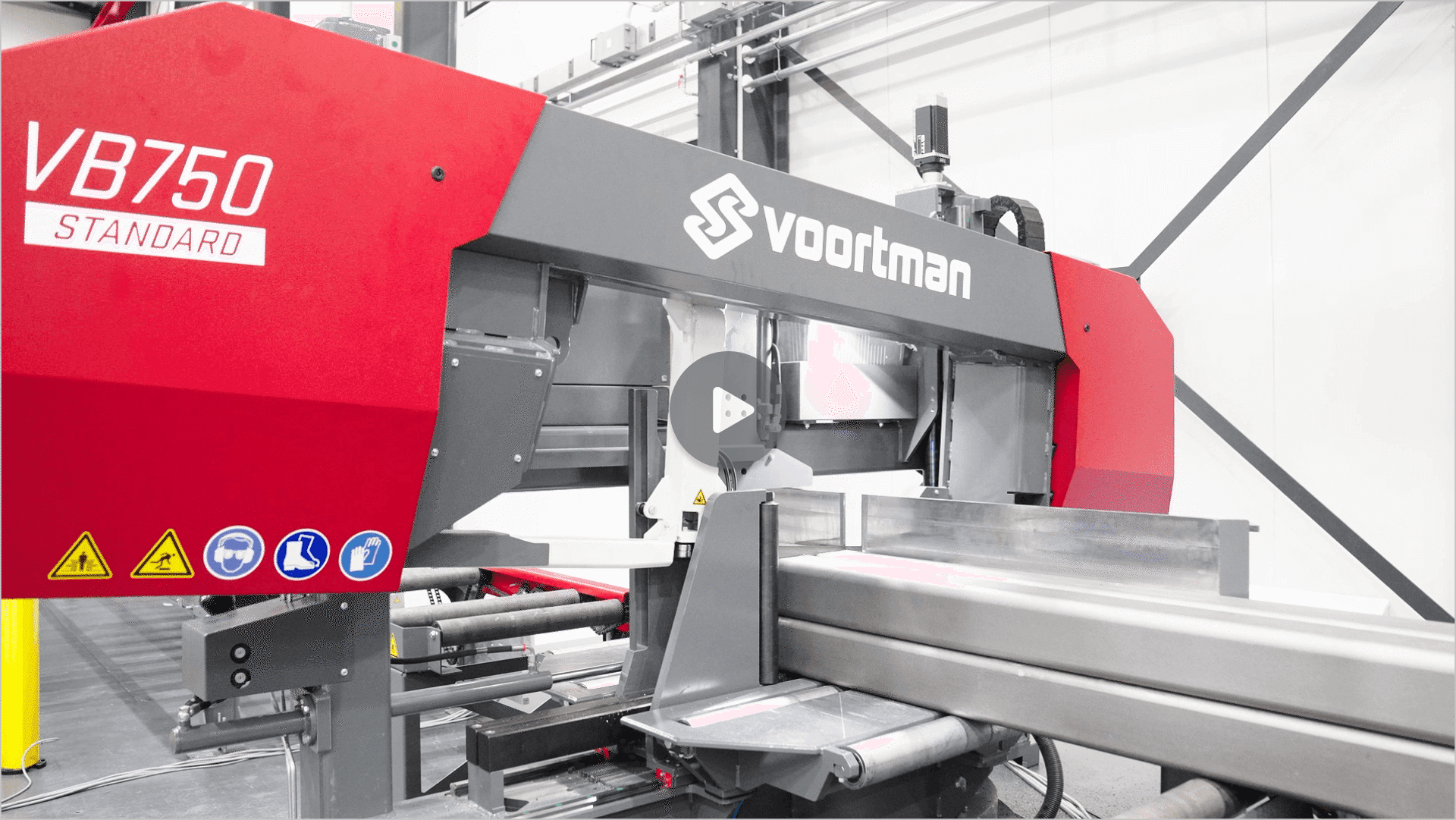

VB Standard DEMO - ready for single and multi-layer bundles

The VB Standard can be equipped with a powerful vertical hydraulic bundle clamp, enabling efficient and precise bundle sawing for a wide range of applications. When installed, the clamp securely handles both single-layer and multi-layer bundles, providing full control and stability throughout the entire cutting process. This ensures uniform pressure distribution across all profiles, minimizing vibration and preventing material slippage during cutting.

In combination with the machine’s servo-driven spindle and dual pressure sensors, the system continuously monitors and adjusts the feed rate based on real-time cutting pressure. This intelligent pressure-based feed control maintains optimal cutting conditions, balancing speed, accuracy, and blade life. The result is consistently clean and precise cuts—achieved significantly faster than with conventional bundle sawing methods—while also reducing wear on the saw blade and other mechanical components.

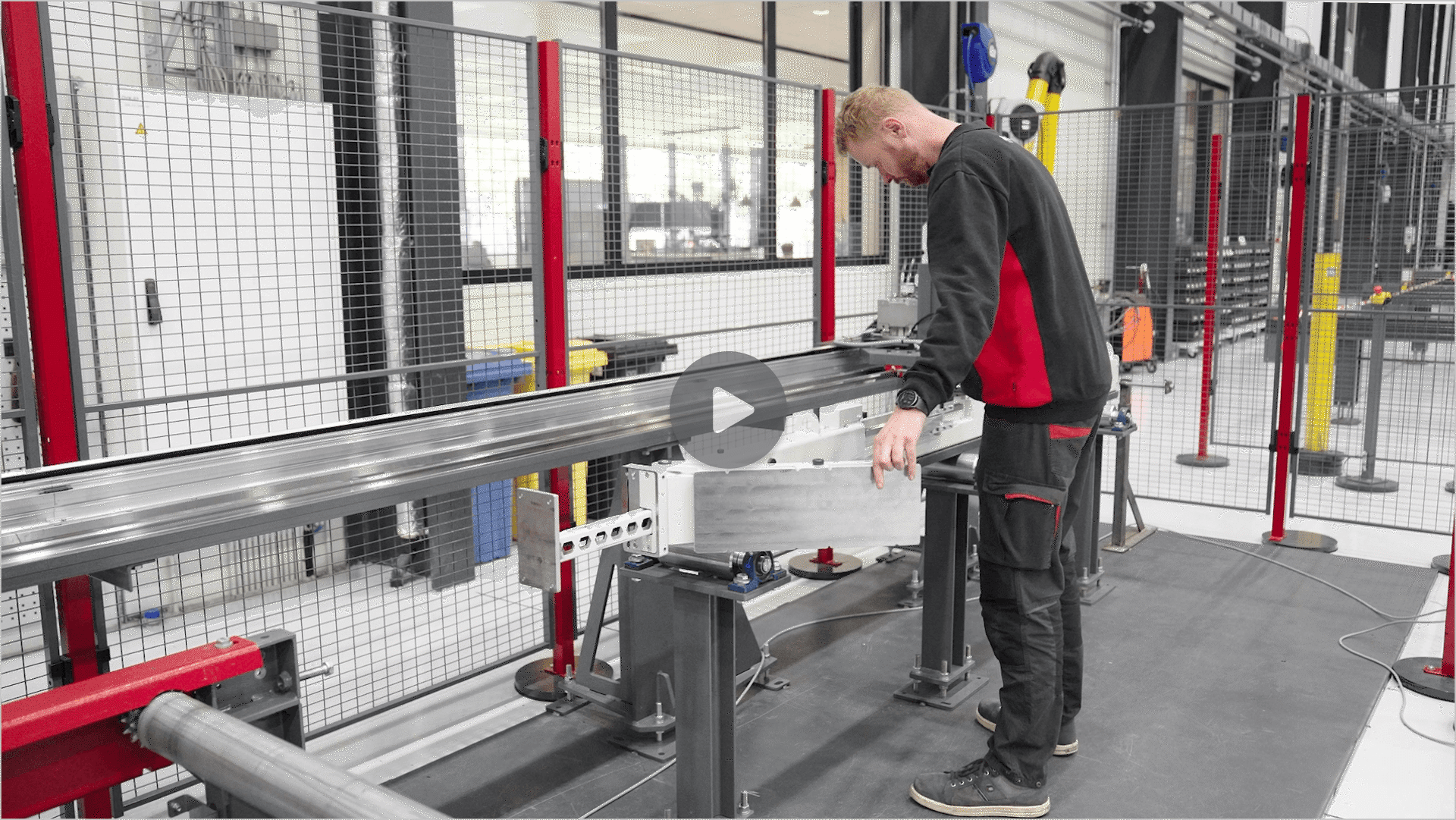

To further enhance productivity, the fast-transition probe truck can be equipped with an optional bundle processing device. This add-on mounts directly to the probe truck and aligns with the detection plate when activated, ensuring that all profiles within the bundle are correctly positioned before cutting begins. Two integrated sensors monitor the device’s activation to guarantee safe and reliable operation during bundle processing.

FAST TRANSITION PROBE TRUCK

Transitioning between single-profile cutting and bundle sawing is exceptionally quick and efficient. The system allows operators to switch modes in less than ten seconds, minimizing downtime and maintaining continuous workflow. Together, these features make the VB Standard an advanced, high-performance solution for both single and bundled profile sawing- offering exceptional speed, accuracy, and ease of operation for modern steel fabrication environments.

REFERENCES & RESOURCES