VB STANDARD

THE COMPACT AND ECONOMICAL CHOICE FOR PRECISION SAWING

The VB Standard combines affordability with advanced engineering, giving manufacturers a powerful, space-saving sawing solution without compromise.

Secure clamping and instant material verification

Compact design with small footprint and fast installation

Double angled frame for outstanding performance

Versatility through range and profile variety

Available models:

VB750 | VB1140

Compatible with:

LogicSteel

OVERVIEW

The VB Standard is a highly versatile sawing solution, designed to meet the needs of manufacturers of any size. Available in two operation ranges - VB750 with a cutting range up to 750 mm (29 in) and VB1140 up to 1140 mm (44 in) - it adapts perfectly to both compact shops and larger production lines. Whether operating as a standalone system with fully automatic infeed, outfeed, and its own precision measuring system, or seamlessly combined with a V630 or V631 drilling line on a compact surface, the VB Standard meets your production requirements with ease.

Its

innovative double-angled frame reduces blade wear, enhances accuracy, and

minimizes footprint, while advanced features such as hydraulic clamping,

servo-controlled feed regulation, automatic step-less mitre cutting, and

integrated mist lubrication deliver maximum performance with minimal downtime.

APPLICATIONS

FEATURES

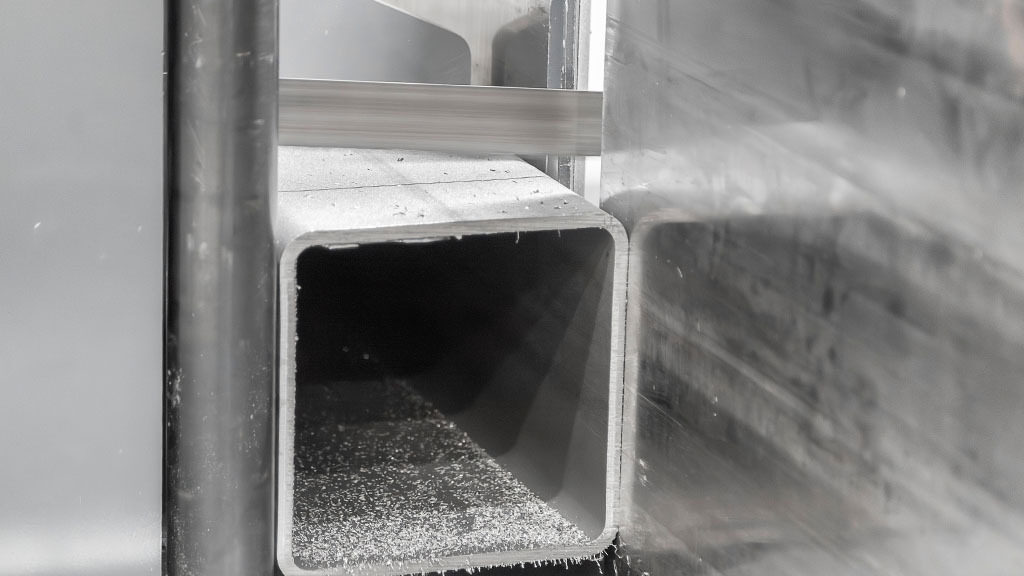

DOUBLE-ANGLED FRAME

The VB Standard’s robust double-angled frame enables smoother operation, extended blade life, and outstanding precision in every cut. The sawing operation is carried out at a 5° angle for optimal material removal and higher sawing speeds. To minimize the required twist in the saw blade, a second 19° angle is integrated into the frame, significantly reducing blade wear and the overall machine footprint.

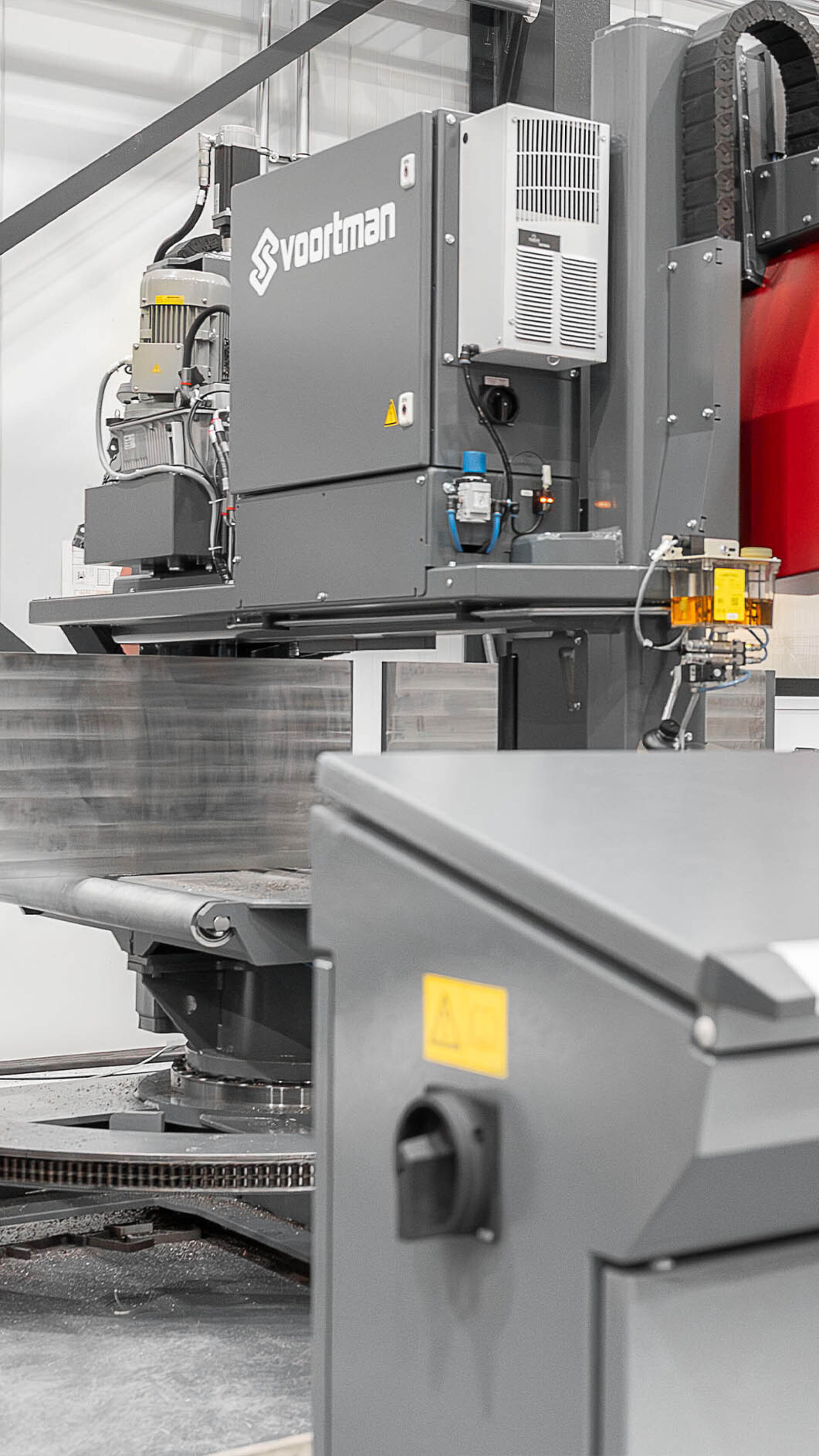

INTEGRATED CABINET

The VB Standard features an integrated electrical cabinet mounted directly on top of the machine housing, providing a compact, space-saving design without sacrificing accessibility or performance. This smart layout keeps all electrical components close to the machine for efficient maintenance while reducing floor space requirements and optimizing overall production area utilization.

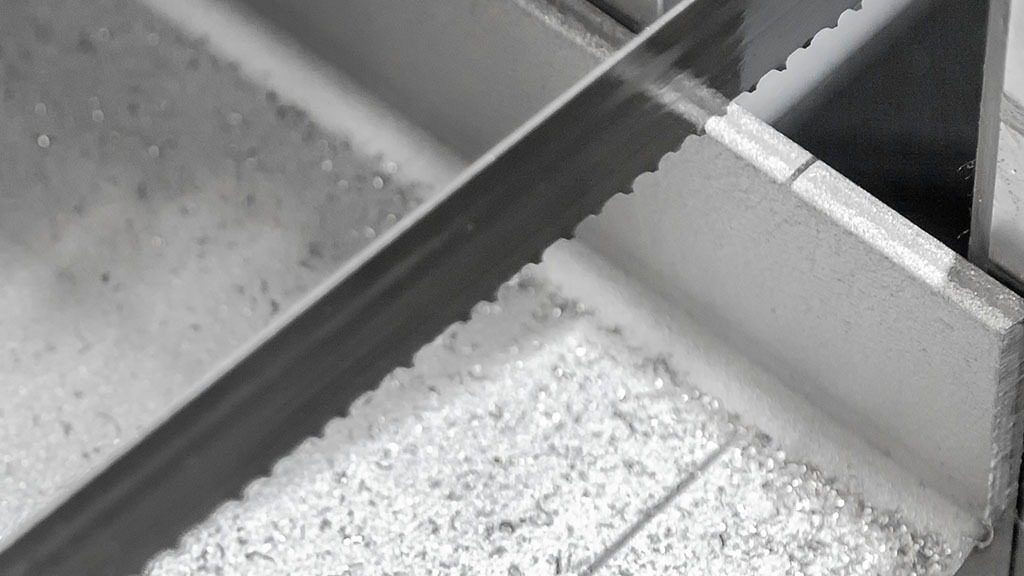

PRECISION FEED CONTROL

A servo-driven spindle with dual pressure sensors keeps feed rates perfectly in check, automatically adjusting if blade pressure gets too high. This ensures precise cuts across the full width and angle of the material, corrects misaligned profiles, and makes bundle sawing faster and fully controlled—more accurate and efficient than conventional methods.

BENEFITS

REDUCED CYCLE TIME

With

a laser guided full-speed approach, the saw reaches the material quickly

and slows only when needed, shortening the sawing cycle and boosting overall

productivity.

CLAMPING AND MEASURING IN ONE

Hydraulic clamps firmly secure the profile, while simultaneous width measurement verifies the material and compensates for mitre cuts. This ensures a stable, precise cutting process and enables accurate part identification by confirming that the loaded profile matches the software data. By prepositioning the clamp based on the incoming profile width, idle time is reduced and productivity increased.

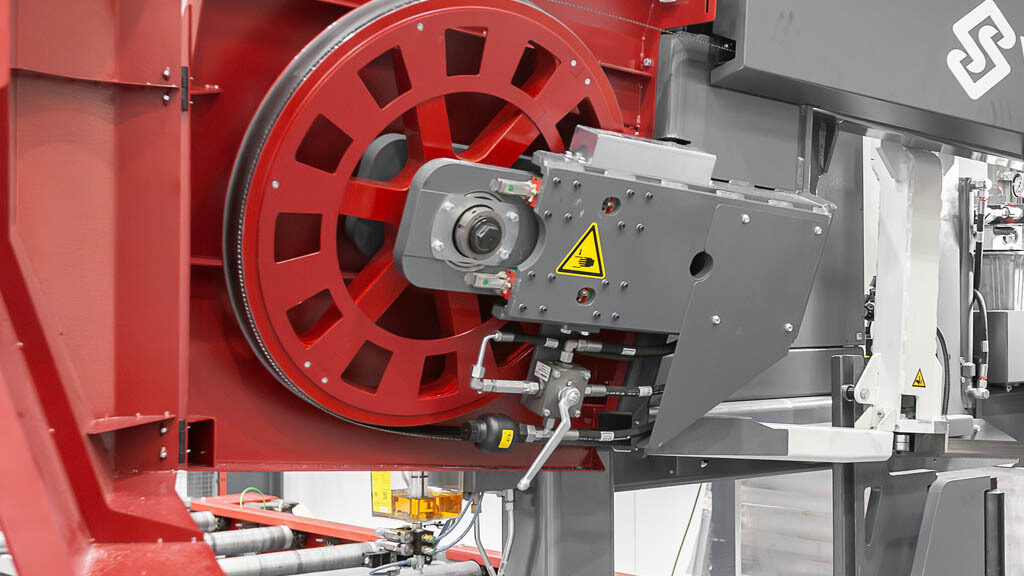

UNINTERRUPTED SAWING

A hydraulic tensioner prevents blade stretching, while mist lubrication with oil and air reduces wear and cleaning requirements, keeping the saw running longer and minimizing interruptions.

EXTENDED BLADE LIFE

The VB standard combines multiple features to extend blade life and ensure consistent, high-quality cutting. Side rollers and low-friction bearings provide precise guidance, while a servo-driven spindle optimizes feed rate. A swarf brush and slow-speed cycle further reduce wear, maximizing durability and performance.

SPECIFICATIONS

VB750

Operating range, width

30 – 750 mm / 1-3/16 – 29 inch

Operating range, height

10 - 460 mm / 3/8 – 18 inch

Max. positioning weight

15.000 kg / 33.000 lbs

Operating mitre angles

+45° and -60°

VB1140

Operating range, width

30 – 1.140 mm / 1-3/16 – 44 inch

Operating range, height

10 - 460 mm / 3/8 – 18 inch

Max. positioning weight

15.000 kg / 33.000 lbs

Operating mitre angles

+45° and -60°

UPGRADE YOUR MACHINE

Add the optional bundle cutting with a hydraulic clamp to your saw for secure, fast, and precise single- or multi-layer sawing.

VB Standard - Standalone performance

Explore the full power of the saw in standalone mode, tailored to your needs for semi- or fully automated operation.

Benefit from an all-economical production line in a compact footprint featuring a Voortman V630 or V631 drilling system.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

Yes. For larger and heavier profiles - or higher system autonomy, we offer the Performance Range, which includes the VB1050 and VB1250 with a maximum profile width of 1250 mm (50 in). Unlike the Standard Range, these saws are also designed for multi-system layouts, allowing multiple saws to operate in a single setup.

Voortman VB saws, in both the Standard and Performance ranges, stand out for their spindle-driven feed, robust construction, rigid frame, and frequency-controlled saw blade, all designed for durability and extended service life.

It depends on your current setup. The Standard Range can replace an existing saw when used in combination with a Voortman V631 or V630 in a back-to-back configuration, or as a standalone unit. The standalone version comes with the new probe measuring system, while an existing back-to-back setup can only be replaced if configured with measuring rolls. If you want to replace a saw in a Multi-System or a back-to-back setup with gripper/feeder truck measuring, the Performance Range is at you're service.

Yes - and it does so with remarkable efficiency. Equipped with a hydraulic bundle clamp, it’s perfectly suited for both single- and multi-level profiles. Sensor-controlled saw blade pressure ensures faster, more precise bundle cutting compared to conventional methods. The new probe truck is designed for speed too, featuring a special bundle add-on that’s easy to activate, with a transition time of less than 10 seconds.

The largest H-profile measures 1140 mm (44 in) wide and 460 mm (18 in) high, with a maximum positioning weight of 15,000 kg (33,000 lbs). For Europe, this corresponds to profiles up to HEA1000, HEB1000, and HEM1000, and for the U.S. to W44×335. To prevent clamping issues, the saw features a slow-speed (Peck) cycle for handling such thick profiles.