VB Standard DEMO - Economical back-to-back drill and saw line

The

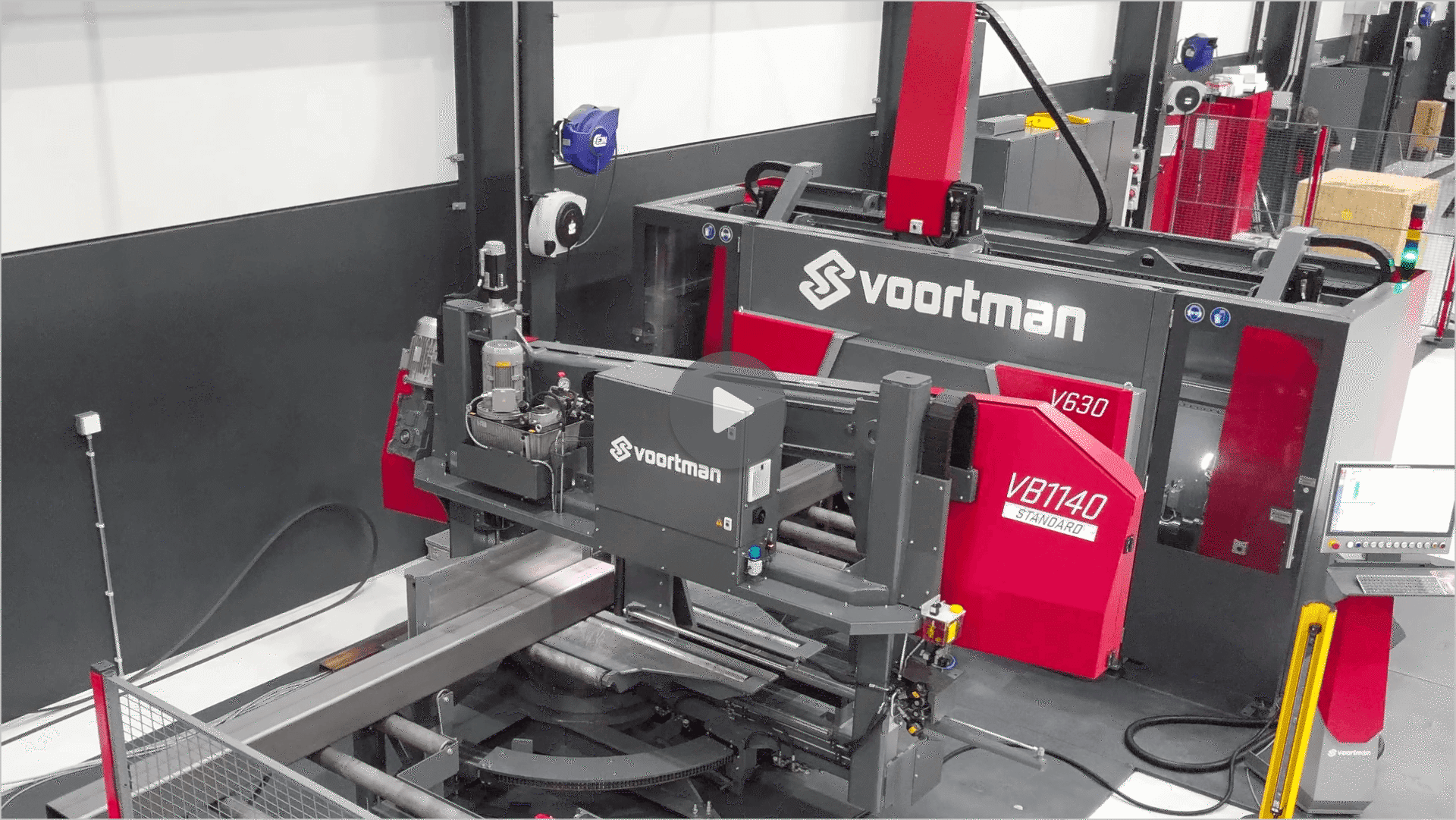

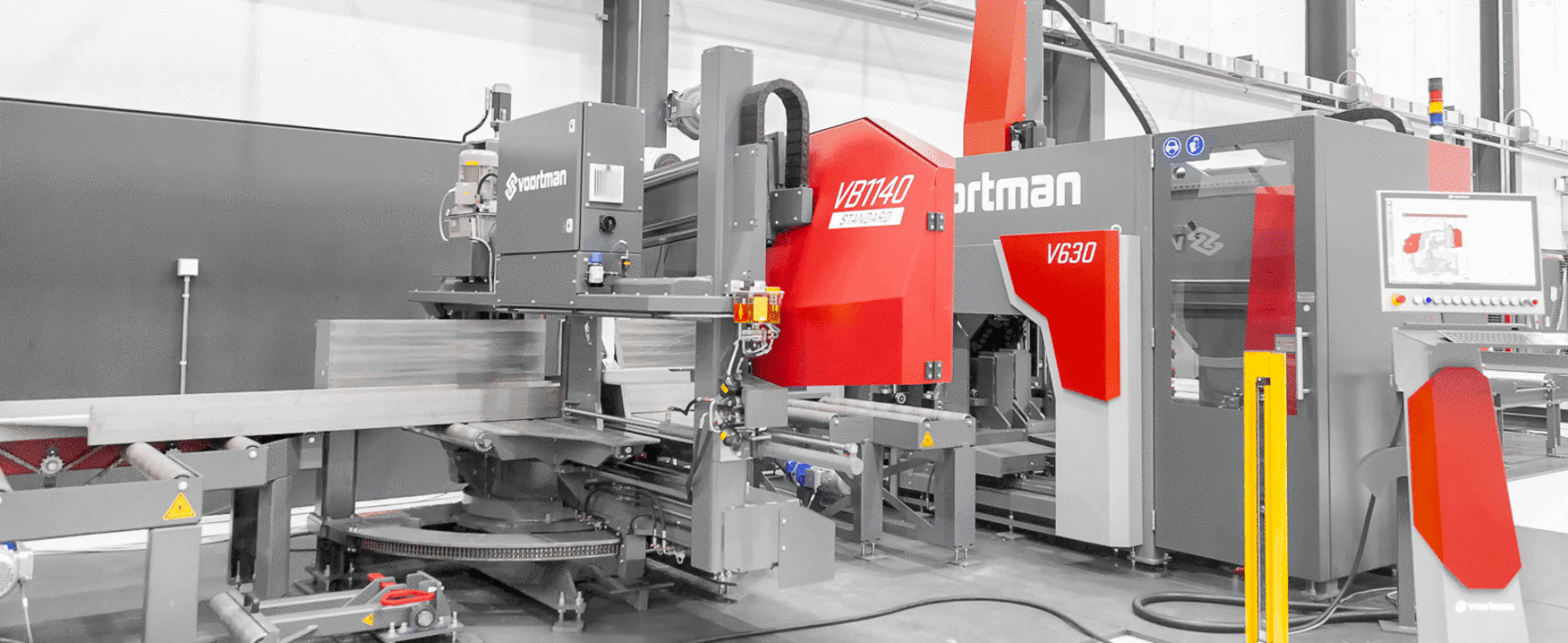

Voortman VB Standard band saws combined with a Voortman V630 or V631 drill in a

back-to-back configuration provide a smart, fully automated solution for

structural steel processing. Working seamlessly together, the drill and saw

handle drilling, tapping, marking, and countersinking with automatic tool

changers, followed by precise mitred or straight sawing, all within one

continuous workflow.

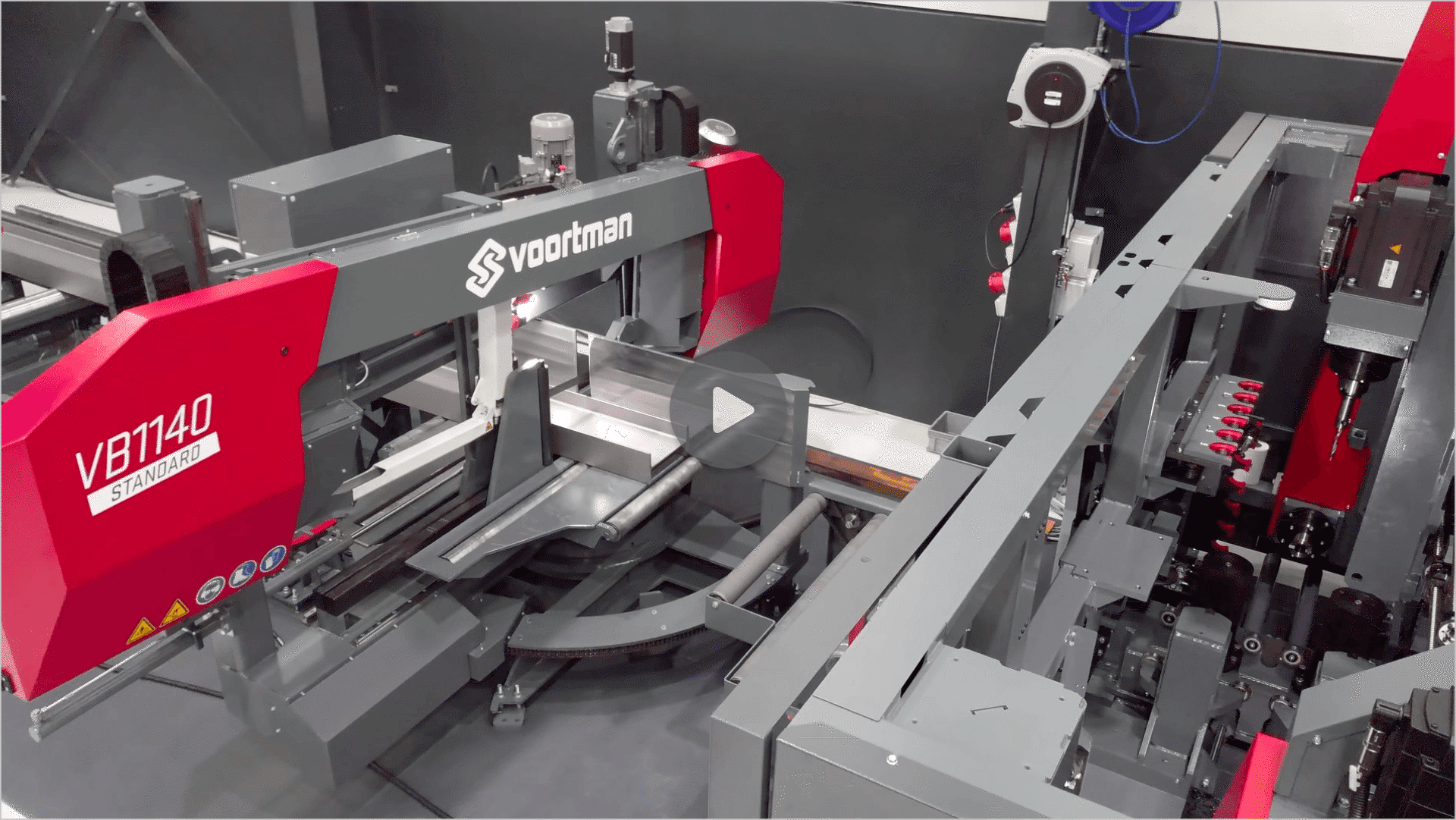

The system also supports backwards processing, allowing

the machines to optimize nestings and automatically process as many profile

lengths as possible through the line without manual intervention. Profiles are

measured only once, ensuring outstanding accuracy and consistency while

reducing handling. With a shared infeed and outfeed supported by efficient

roller conveyors, this compact setup maximizes throughput, precision, and

overall productivity.

EXAMPLE ONE

batch processing of square tubes with drilled holes

A batch of square tubes is

processed for two different products. Each tube undergoes fully automated

drilling on three sides. The system then performs

precise straight sawing, cutting each tube to the correct lengths for

both products. Automatic clean-cut and off-cut management ensures that scrap is

separated and handled efficiently.

Integrated infeed and outfeed conveyors move

the profiles seamlessly through the line, allowing both products in the batch

to be processed continuously with minimal manual intervention. All drilled

holes align perfectly with the sawn lengths, while smart nesting and backwards

processing optimize material usage, maximizing throughput and reducing waste.

EXAMPLE TWO

i-profile with multiple cut-to-length products and automatic outfeed

A single long I-profile is

processed in a batch configured for one long product and three short products. After drilling, the system performs a

clean cut and separates off-cuts efficiently. Using backwards processing, the

long profile is then cut into multiple products to length. While three smaller

products are produced and can be manually removed, the main longer product

remains in the line and is automatically outfed via the integrated conveyor

system.

This workflow ensures precise hole alignment, minimizes handling, and

maximizes automation for both the long product and the smaller off-cuts.

REFERENCES & RESOURCES