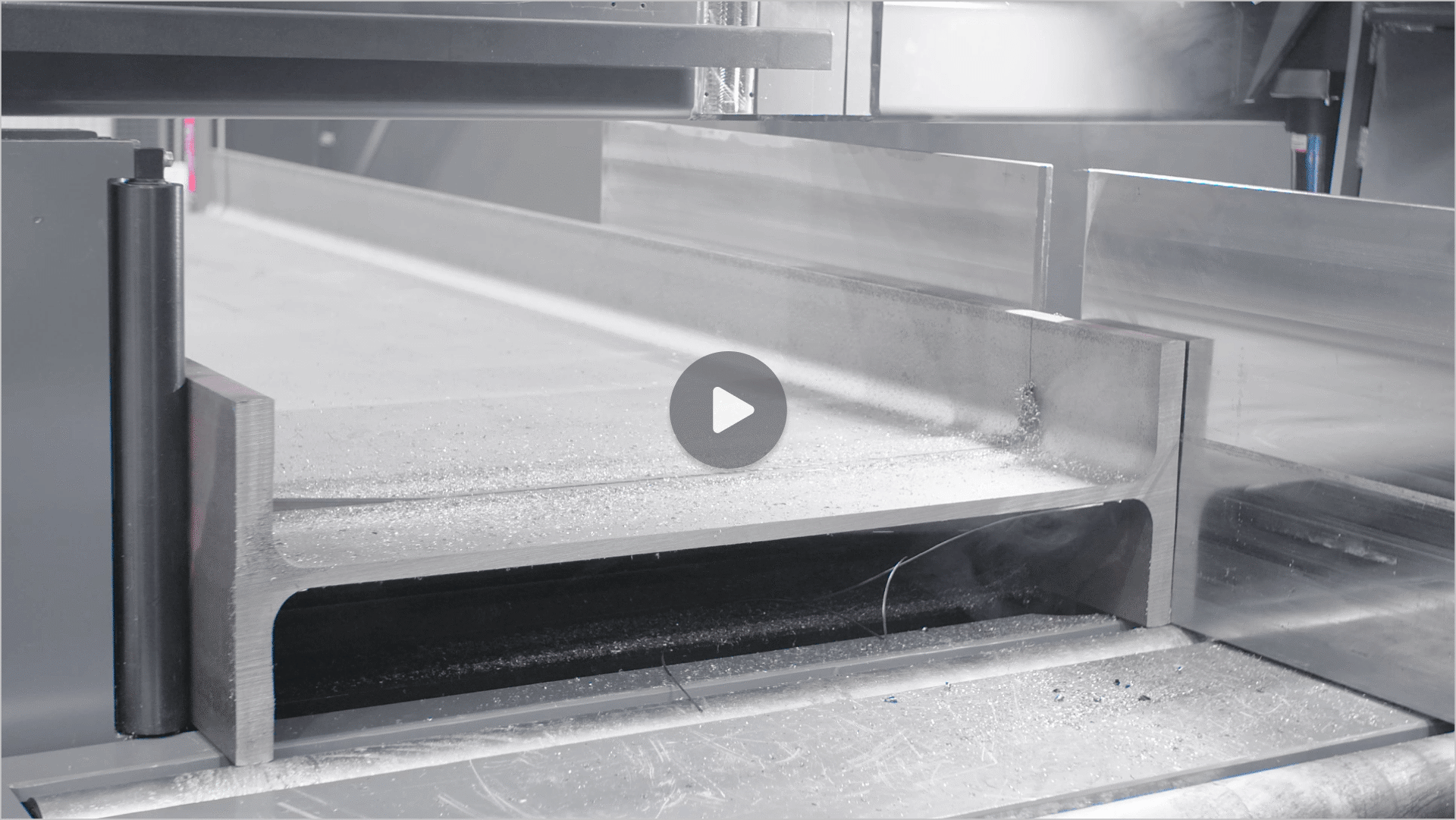

DEMO - Sawing a wide range of profiles

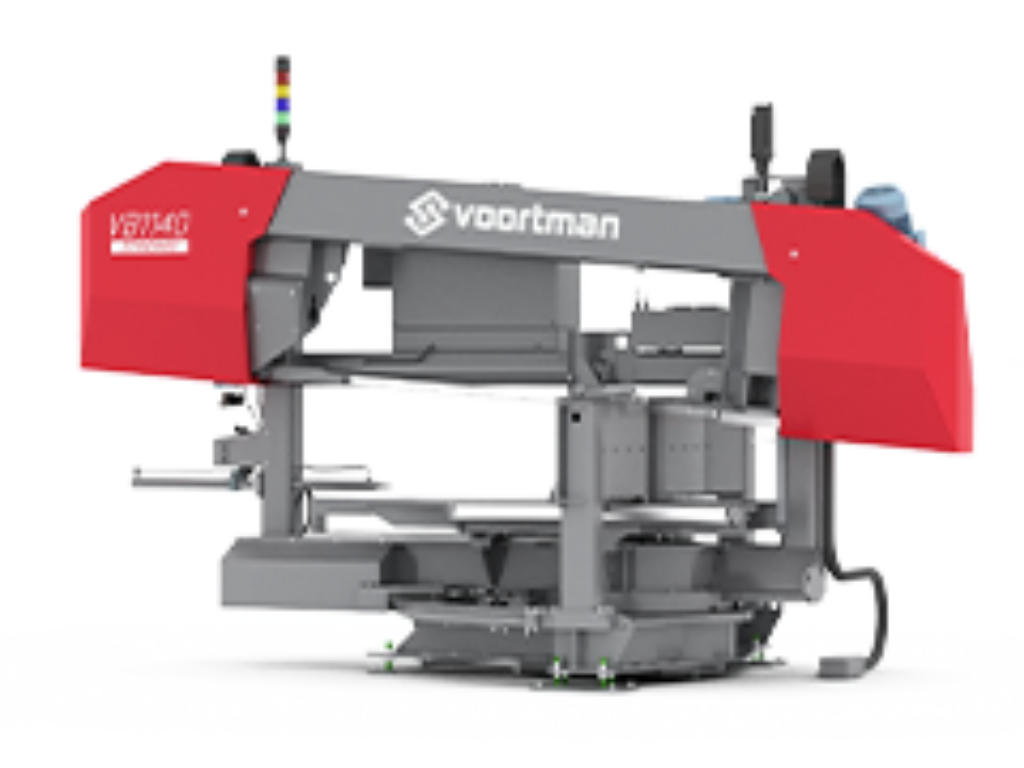

The VB Standard is a highly versatile cutting system capable of handling an exceptionally wide range of steel profiles with outstanding precision and reliability. It efficiently processes everything from small tubes and angles as compact as 30 mm × 30 mm (1-3 in × 1-3 in) to large and heavy-duty structural sections. At the upper end of its range, the VB Standard can cut H-beams measuring up to 1140 mm (44 in) wide and 460 mm (18 in) high, accommodating workpieces with a maximum positioning weight of 15,000 kg (33,000 lbs).

This broad capability allows fabricators and steel processors to complete diverse projects on a single machine - eliminating the need for multiple systems or time-consuming manual handling between processes. Whether cutting small precision components or massive structural beams, the VB Standard maintains a high degree of accuracy and repeatability, ensuring every cut meets tight tolerance requirements.

To further enhance performance on thicker, heavier materials, the machine employs a specialized “slow-speed-cycle.” This feature minimizes vibration and prevents clamping issues that can occur when working with large or dense profiles. By controlling movement and feed rate with exceptional precision, the system delivers smooth, stable cutting performance even under challenging conditions.

The result is consistently clean, square cuts across all material sizes, with minimal rework or finishing required. Combined with its robust construction and advanced motion control, the VB Standard stands out as a dependable, high-capacity solution for workshops and fabrication facilities seeking both flexibility and precision in steel profile processing.

REFERENCES & RESOURCES