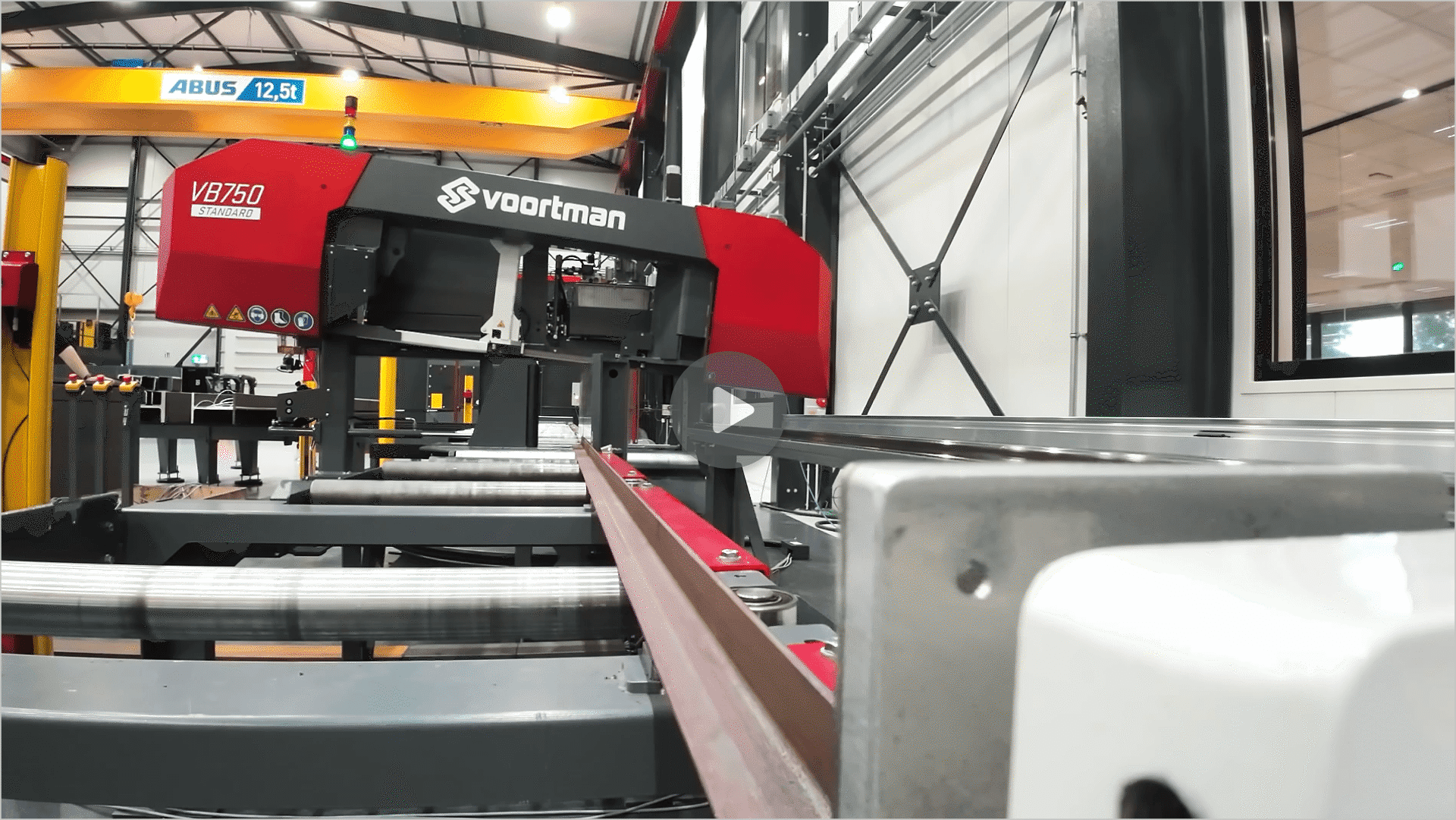

VB Standard DEMO - Sawing a variety of profiles

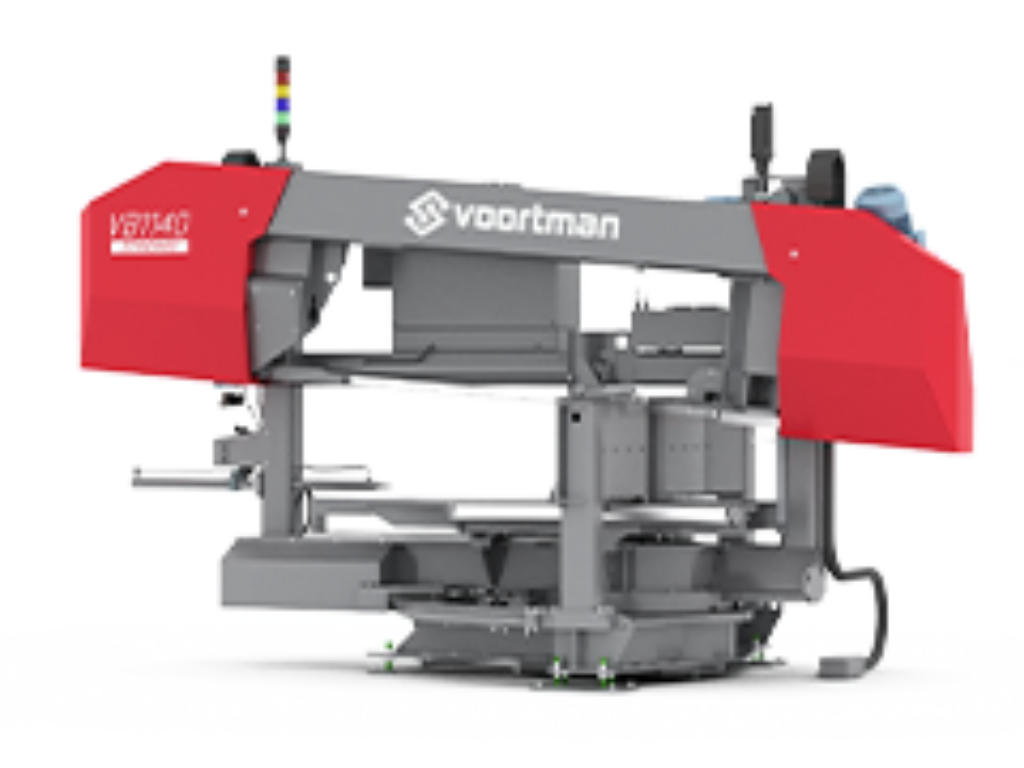

The VB Standard is engineered to deliver highly accurate and efficient sawing performance across a wide variety of steel profiles. It easily handles H-beams, square and rectangular tubes, angles, UNP channels, and T-profiles with exceptional precision and reliability. The system’s servo-driven spindle ensures a controlled and consistent feed rate, maintaining smooth operation throughout every cut.

Two pressure sensors, mounted directly above the saw blade, continuously monitor the actual sawing pressure across the full width and cutting angle. This real-time feedback allows the system to automatically adjust the feed speed for optimal performance and tool life. The result is extremely precise, direct feed regulation that guarantees consistent quality, even when processing slightly misaligned or irregular profiles.

To further enhance stability and reduce wear, the machine features four transport rolls - two on each side of the saw - that provide full-width material support and minimize friction during movement. The combination of robust sawing tables and wear-resistant saw lists helps protect both the material surface and the saw band itself, significantly extending their service life and ensuring smooth, uninterrupted operation.

An advanced - laser guided - full-speed approach system adds another layer of efficiency. This intelligent feature allows the saw to travel at maximum speed until it nears the workpiece, at which point it automatically slows to the ideal cutting feed rate. This transition optimizes cutting time without compromising precision or surface finish. Together, these innovations make the VB Standard a reliable and high-performing sawing solution for steel fabrication and structural processing applications.

REFERENCES & RESOURCES