COMPACT BACK-TO-BACK DRILL SAW LINES FOR STRUCTURAL STEEL

Looking for maximum throughput with your drilling & Cutting processing operations?

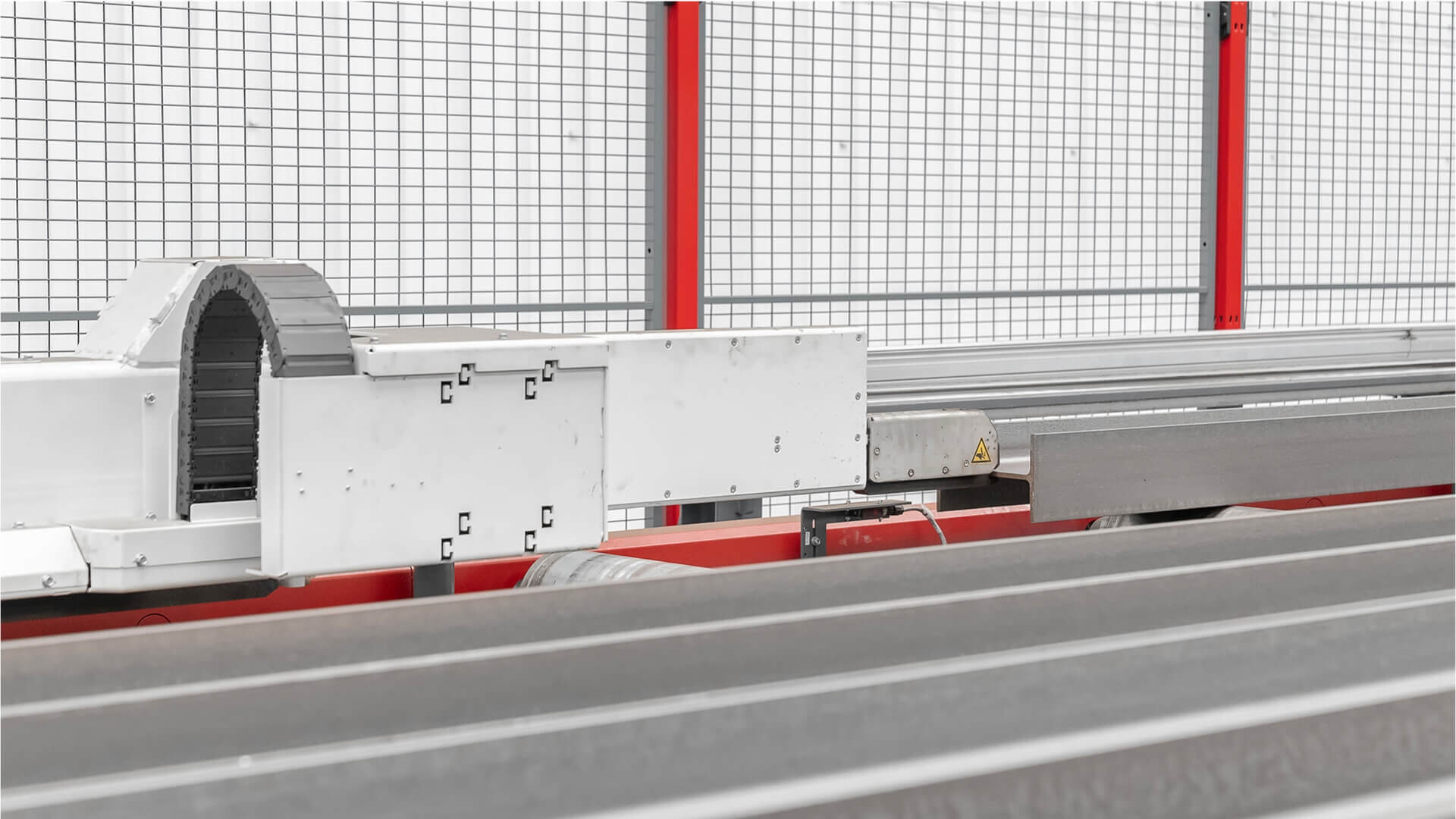

Voortman’s Back-to-Back configuration combines the V630, V631, or V633 with a VB saw into one seamless drill saw line. This setup eliminates extra handling, reduces floor space, and delivers connection-ready profiles in a single flow. Whether you're drilling, milling, tapping, or cutting – this drill saw line is built for productivity.

REQUEST MORE INFO EXPLORE MACHINES

BACK-TO-BACK ADVANTAGES THAT MATTER

With just one operator, both machines can be managed from a single station, ensuring full control and streamlined operation. Advanced automation reduces errors and boosts consistency, making the system highly reliable. Designed to scale with your business, it’s an ideal solution for both mid-sized fabricators and large-scale distributors looking to increase throughput without compromising quality.

CUTTING & DRILLING, ALL IN ONE SETUP

The Back-to-Back layout connects a Voortman drill and saw machine into a single production line.

- Single measurement: Profiles are measured once, then drilled and cut without repositioning.

- Shared input/output: Simplifies logistics and reduces crane or forklift usage.

- Compact footprint: Ideal for fabricators with limited space and high output demands.

DRILLING & MILLING MACHINES – V63X SERIES

VOORTMAN V630

- Compact and powerful for structural steel

- 3 spindles, automatic tool changers

- Ideal for drilling, milling, tapping, and marking

VOORTMAN V631

- High-speed milling with 290 cm³/min removal rate

- 8-station tool changers per spindle

- Built for high-volume production

VOORTMAN V633

- Industry-leading speed for multi-side processing

- 14-station tool changers, servo-driven sub-axes

- Perfect for demanding, automated environments

ONE WORKFLOW. TOTAL ACCURACY

VB SAW RANGE – PRECISION CUTTING WITH FULL AUTOMATION

The Voortman VB Range CNC bandsaws are designed for automated straight and miter cutting of structural steel.

- Stable cutting: Welded base frame ensures consistent pressure and blade tension.

- Extended blade life: Swarf brush and optimal force control reduce wear.

- Short Product Removal System (SPRS): Cleanly removes small cuts for uninterrupted flow.

- LED projection system: Accurately positions the saw blade for precise cuts.

- Flexible measurement systems: Choose from gripper truck, full-stop, or roller-based systems to match your production needs.

INTEGRATED PROFILE MEASUREMENT – ACCURACY THAT CONNECTS

In a Back-to-Back drill saw line, precision begins with the first measurement. Using either a gripper truck or roller feed system, Voortman ensures each profile is measured once and processed by both machines without interruption. This shared measurement setup eliminates repositioning, aligns drilling and cutting perfectly, and keeps your workflow fast and consistent.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.