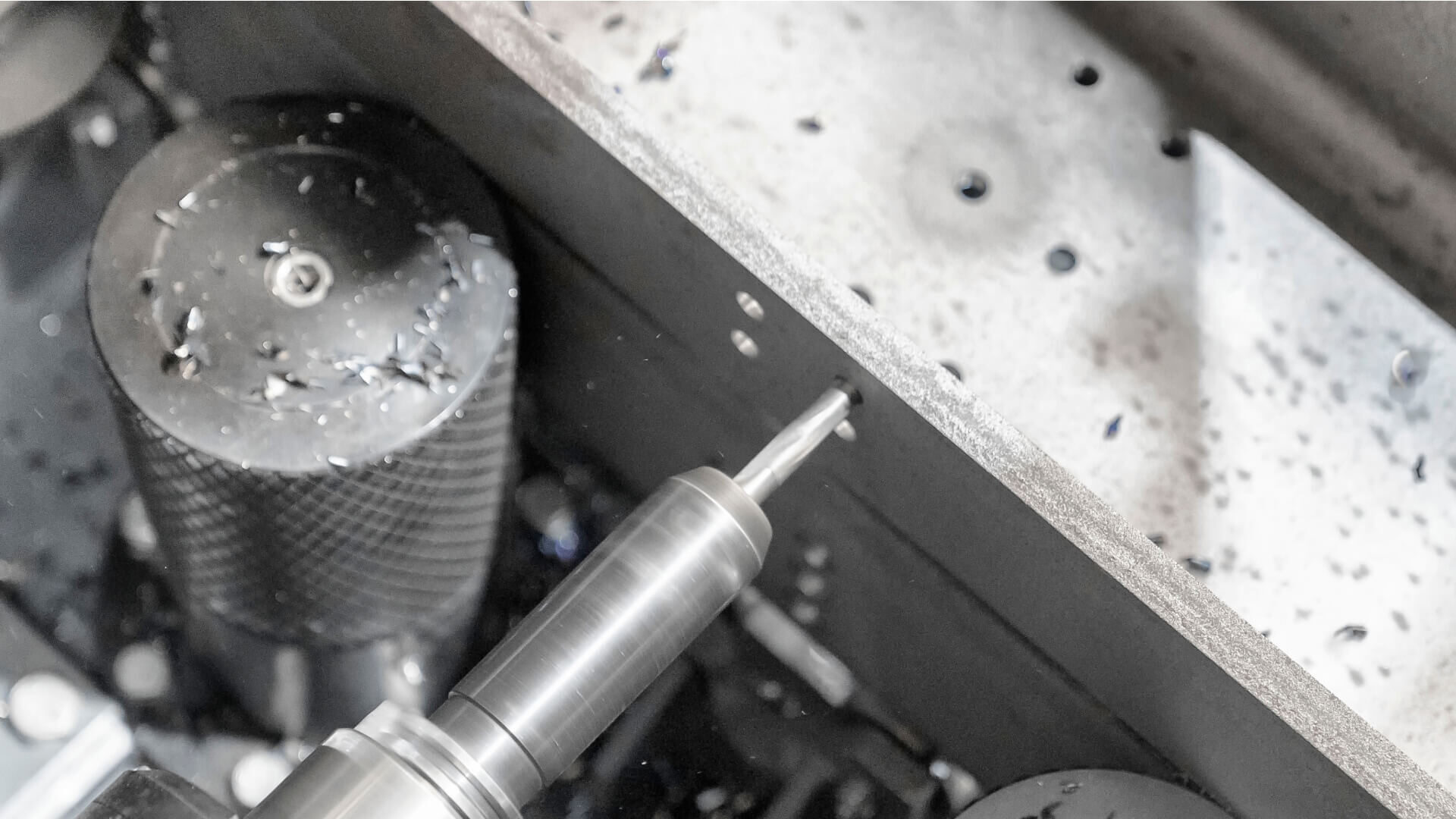

HIGH-SPEED CNC BEAM DRILLING MACHINES FOR STRUCTURAL STEEL AND MAXIMUM THROUGHPUT

Looking for fast, precise drilling for structural steel?

Looking for a high-performance CNC steel drilling machine for structural steel? Voortman offers a complete range of beam drill machines designed for maximum output, automation, and accuracy. Whether you're processing I-beams, H-beams, channels, or tubes, our machines deliver weld-ready profiles in one run. From standalone drilling to fully integrated production lines, the V630, V631 and V633 are engineered to reduce labor, increase output, and simplify operations.

REQUEST MORE INFO EXPLORE MACHINES

BEAM DRILLING MACHINES

VOORTMAN V630

The Voortman V630 is a compact powerhouse for structural steel drilling. With three independently operating drill heads and automatic tool changers, it handles drilling, milling, tapping, and marking in one setup. VACAM and LogicSteel software automates tool paths and nesting, reducing manual input and increasing throughput. Ideal for fabricators seeking reliability and efficiency in a smaller footprint.

- Type: CNC beam drilling & milling machine

- Material: H, I, U, T, L, square tube and flat bar

- Processing Range: Width up to 1,140 mm (44")

- Processing capabilities: Drilling, milling, countersinking, thread tapping, numbering, layout & centerpoint marking, inner and outer contours

- Automation: Fully autonomous

- Features: 3 spindles, 3 x 6-station tool changer, VACAM and LogicSteel software integrations.

VOORTMAN V631

The Voortman V631 delivers the fastest milling in the market with a material removal rate of 290 cm³/min and rotational speeds up to 4,500 rpm. Each drill head supports up to 8 tools, enabling full multi-process automation. Built with premium components and VACAM and LogicSteel software integration, it ensures high accuracy, reduced labor, and long-term reliability. Perfect for high-volume steel fabricators.

- Type: CNC beam drilling & milling machine

- Material: Structural steel profiles (I/H beams, channels, tubes)

- Processing range: Width up to 1,050 mm (41") or 1,250 mm (50")

- Processing capabilities: Drilling, milling, countersinking, thread tapping, numbering, layout marking, inner and outer contours & weld preps/ratholes

- Automation: Fully autonomous

- Features: 3 spindles, 3 x 8-station tool changer, VACAM and LogicSteel software for optimized sequencing and roller feed or gripper truck for profile measuring

VOORTMAN V633

The Voortman V633 is the fastest in the industry for simultaneous multi-side processing. With four sub-axes, rotational speeds up to 5,000 rpm, and advanced clamping systems, it delivers unmatched throughput for demanding production environments. Ideal for large-scale, automated steel fabrication lines.

- Type: CNC beam drilling & milling machine

- Material: Structural steel profiles, including small profiles down to 50 mm

- Processing Range: Width up to 1,140 mm (44")

- Processing Capabilities: Drilling, milling, countersinking, thread tapping, numbering, layout & centerpoint marking, simultaneous inner and outer contours & weld preps/ratholes

- Automation: Fully autonomous

- Features: 3 spindles with stroke in X 300 mm (11 13/16"), 3 x 14-station tool changer, VACAM and LogicSteel software for full automation, servo-driven sub-axes for multi-side processing.

MEASURING SYSTEMS

Precision that drives performance. Accurate measuring is key to perfect drilling and cutting. Voortman offers two advanced options, a gripper truck for heavy profiles and high-speed automation, and measuring rolls for continuous, real-time accuracy in compact setups. Both ensure precision and flexibility for any production needs.

GRIPPER TRUCK / FEEDER TRUCK

Clamps and moves profiles with absolute accuracy. Ideal for high-speed automation and heavy profiles, reducing cycle times and ensuring repeatable precision.

MEASURING ROLL / FEEDING ROLLS

Provides continuous measurement during feeding for real-time accuracy. Perfect for smaller profiles and compact layouts, eliminating manual measuring and minimizing errors.

FROM DRILLING TO CUTTING BACK-TO-BACK EFFICIENCY

Imagine drilling and cutting profiles without the need to move them between separate machines, Voortman’s Back-to-Back Drill Saw Line makes this possible by integrating the V63x drill machine and VB bandsaw into a single, cohesive system. With just one measurement, both drilling and sawing are performed in a continuous flow, significantly reducing handling time and eliminating the need for extra crane movements. This compact configuration not only saves valuable floor space but also delivers speed and precision, making it an ideal solution for workshops aiming to enhance efficiency without expanding their layout.

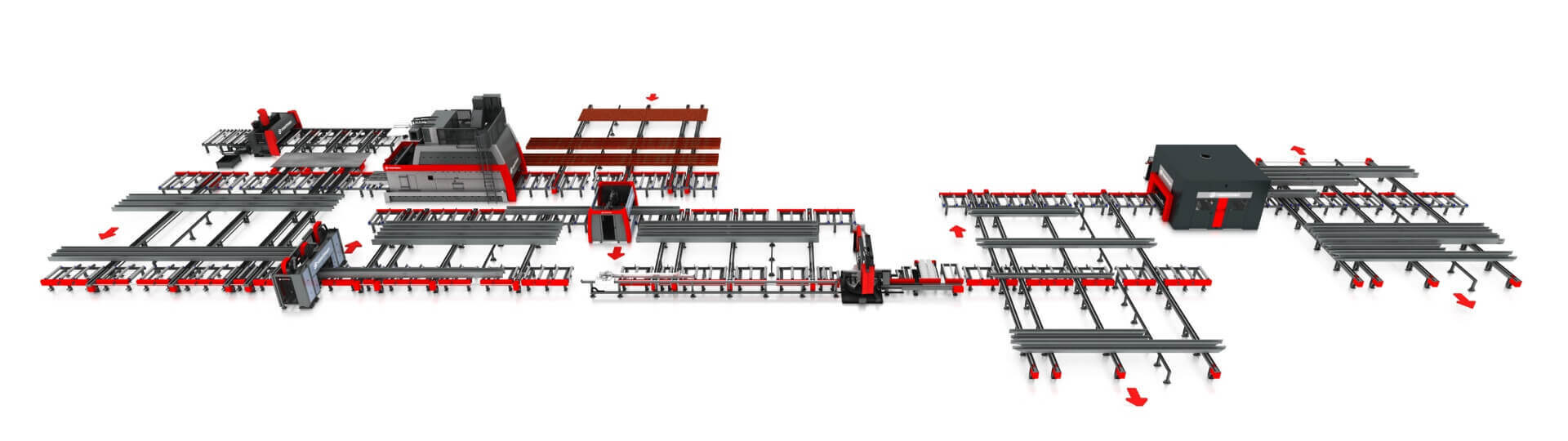

SMART FACTORIES MADE SIMPLE: MSI INTEGRATION

For steel fabricators and distributors seeking full automation, Voortman’s Multi System Integration (MSI) offers a transformative solution. By seamlessly connecting machines such as drills, saws, and coping robots through conveyors and buffer zones, MSI enables a fully integrated workflow. Powered by VACAM intelligence, production data is distributed across all systems for real-time optimization, drastically reducing manual labor. Material flows automatically, eliminating bottlenecks and significantly increasing throughput. With LogicSteel MRP, users gain complete control over their factory operations, from 3D modeling to final delivery, through a unified platform for planning, scheduling, and reporting. Ultimately, MSI converts your workshop into a smart factory, minimizing manhours per ton and ensuring consistent, high-volume output.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.