AUTOMATED BEAM AND PROFILE PROCESSING MACHINES FOR STRUCTURAL STEEL

Looking to streamline and maximize efficiency in every cut with your beam processing operations?

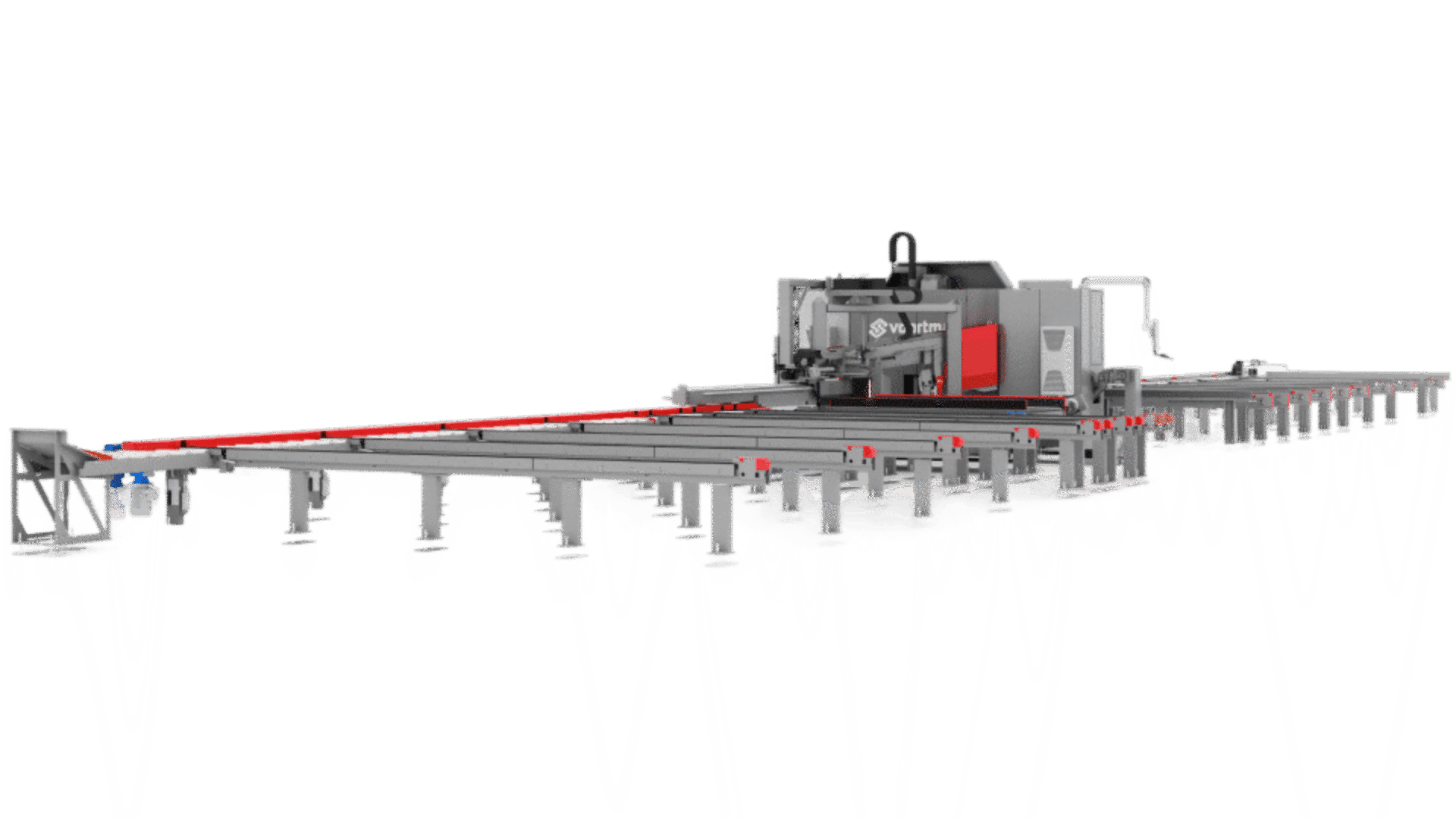

Voortman offers a complete portfolio of CNC machines for drilling, milling, sawing, robotic plasma cutting, and laser cutting. Whether you're processing H-beams, I-beams, tubes, or miscellaneous profiles, Voortman delivers unmatched flexibility and automation. From compact drill-saw lines to fully integrated MSI systems, Voortman machines are built to deliver speed, precision, and reliability.

REQUEST MORE INFO EXPLORE MACHINES

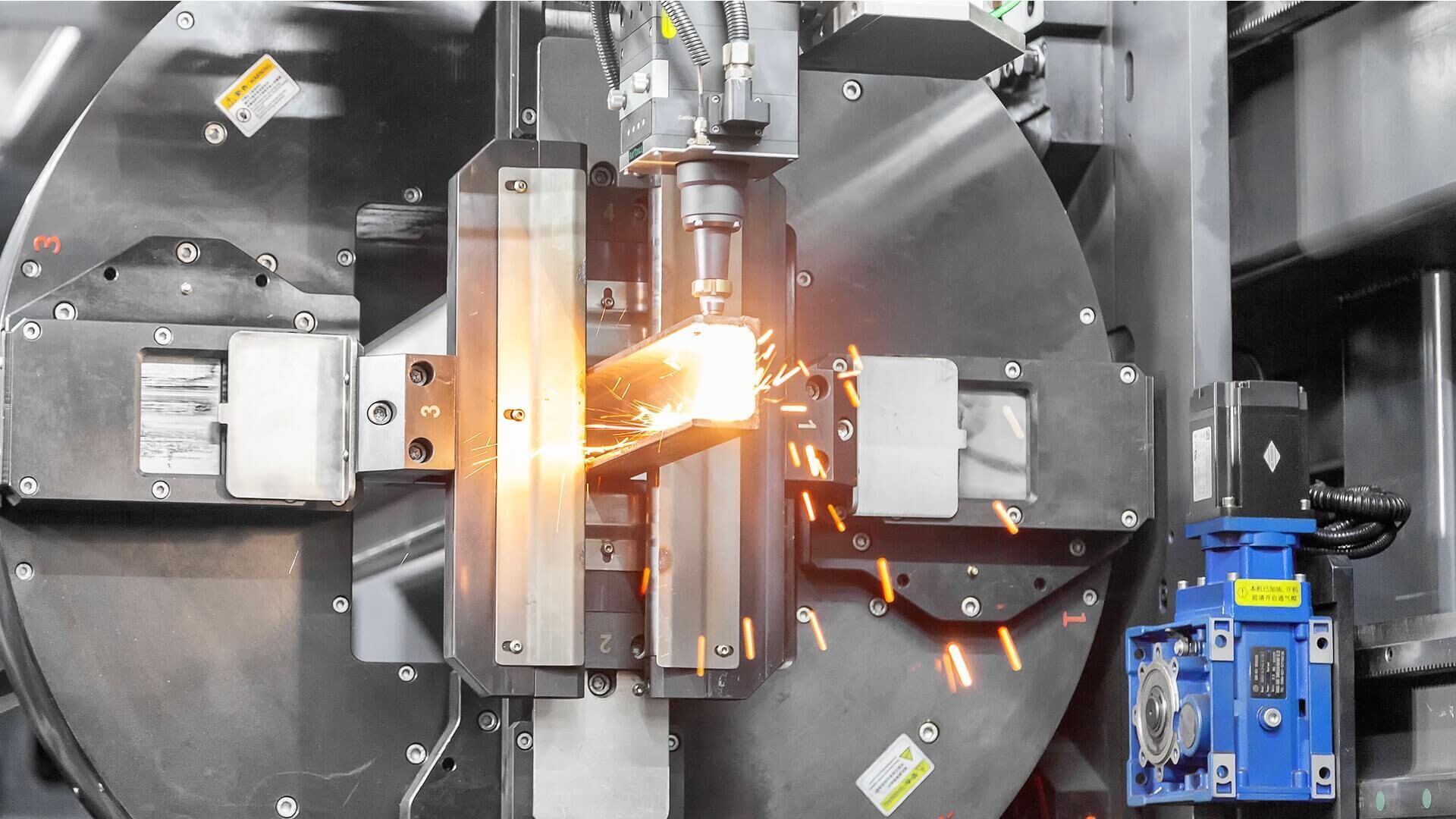

ROBOTIC PLASMA BEAM CUTTING MACHINES

FLEXIBLE AND COST-EFFECTIVE FOR COMPLEX SHAPES

Robotic plasma cutting, powered by smart software and automatic angle compensation, is a compact and cost-effective solution for processing complex steel shapes.

- Cuts bolt holes, slots, bevels, and markings in one pass

- Handles mixed geometries and medium-thickness materials

- Reduces tool change downtime for varied hole sizes

- Offers full geometry freedom with machines like the V807

- Delivers a fast return on investment

However, for very small holes, where the diameter is smaller than the material thickness, cut quality may decrease, and taper or heat-affected zones might require post-processing.

VOORTMAN V807

The Voortman V807 combines multiple processes into one compact footprint. It replaces drilling, milling, sawing, and marking with robotic plasma cutting. No manual programming needed, just import DSTV files. Ideal for fabricators needing flexibility and speed in one machine.

- Type: Robotic plasma cutting machine

- Material: Structural steel profiles up to 1,140 mm

- Processing Capabilities: Bolt holes, copes, slots, weld preps, notches, bevels, layout marking

- Automation: Fully automated

- Features: Robotic arm with full geometry freedom, VACAM and LogicSteel software

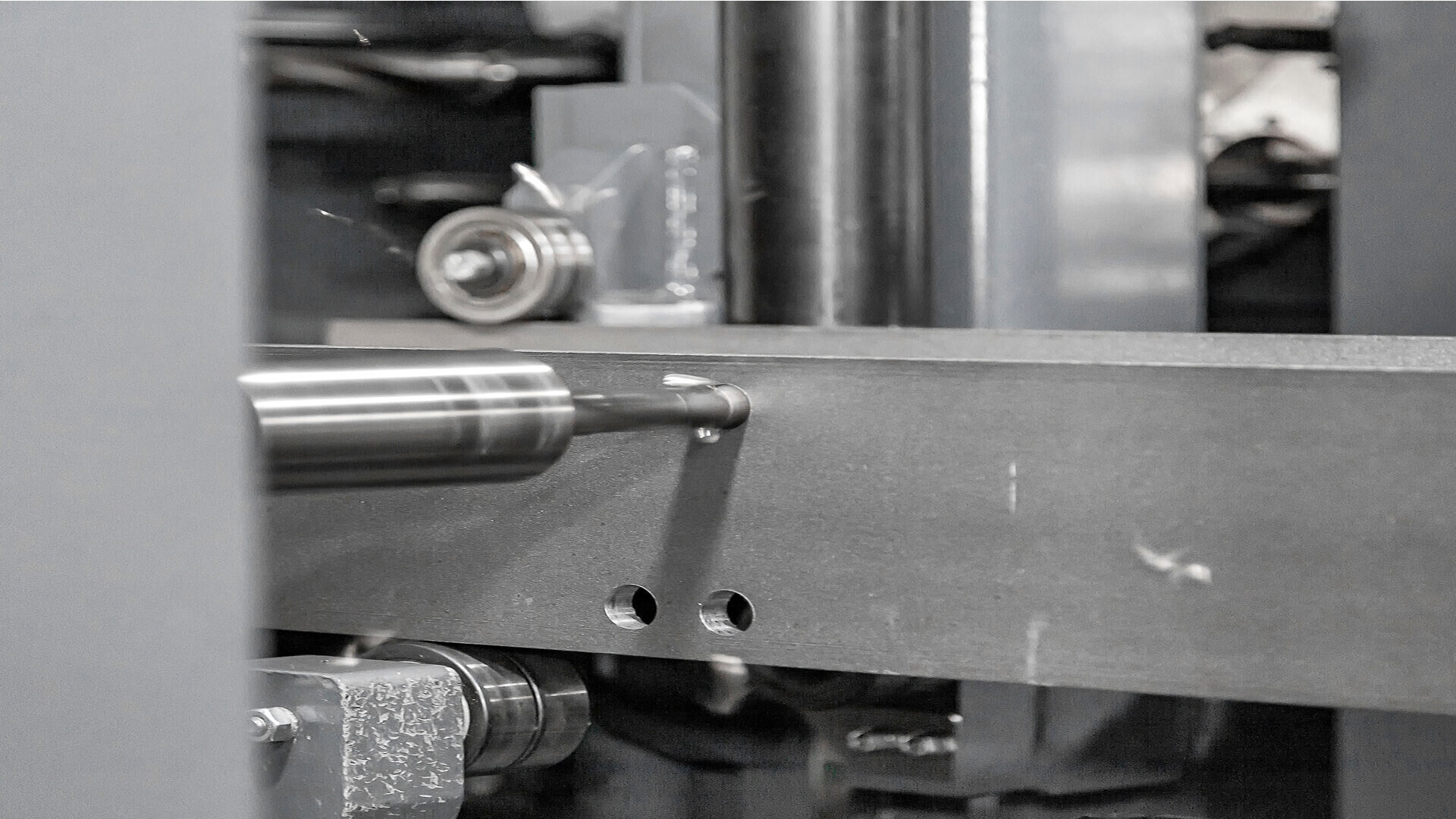

FULLY AUTOMATED LASER PROCESSING MACHINES

HIGH-END PRECISION FOR THIN TO MEDIUM PROFILES

Laser cutting delivers high-end precision for thin to medium-walled tubes and profiles, making it ideal for architectural steel and premium fabrication.

- ±0.1 mm accuracy with clean, burr-free edges

- No tool wear or taper, ensuring consistent quality

- Minimal rest material, down to just 5 mm

- Fiber laser with automatic centering and multi-chuck clamping

- V845 processes round, square, and H/I profiles up to Ø500 mm with high-speed positioning

While laser systems offer exceptional precision, they come with a higher investment cost and are less effective on very thick materials.

VOORTMAN V845

The V845 delivers ±0.1 mm cutting precision with automatic centering and adjustable clamping force. It handles up to 2.4 tons and supports high-speed positioning (45 m/min). With minimal rest material (5 mm) and infinite chuck rotation, it maximizes material use and productivity. Ideal for heavy-duty tube and profile cutting with minimal rework.

- Type: Heavy-duty laser cutting machine for tubes and profiles

- Material: Round tubes, square tubes, H/I beams

- Processing Range: Width up to 350 mm

- Processing Capabilities: Laser cutting, bevel cutting, backside processing, automatic centering, minimal post-processing

- Automation: Fully Automated

- Features: 3 rotating chucks, infinite rotation, VACAM software, advanced nesting, semi-automatic loading system

BEAM DRILLING MACHINES MACHINES

PRECISION AND SPEED FOR SMALL AND THICK PROFILES

Carbide drilling is the preferred method for high-precision holes in thick materials, especially when tight tolerances and clean finishes are essential.

- Faster than plasma for small holes (e.g. 14–22 mm in 12 mm thick steel)

- Superior quality when hole diameter is smaller than material thickness

- Minimal taper and no heat-affected zone

- Ideal for connection-ready profiles with tight tolerances

- Machines like the V623, V630, V631, and V633 offer high-speed drilling with up to 14-tool changers and 5,000 rpm spindles

While carbide drilling excels in precision, it’s slower when many different hole sizes are needed and less suitable for complex geometries like copes or bevels.

VOORTMAN V623

The V623 is Voortman’s most autonomous machine. It features a gripper truck for automatic profile loading and VACAM software for full visibility of buffers and zones. Designed for continuous production with minimal operator input, it’s perfect for high-mix, low-volume environments.

- Type: Autonomous drilling, milling & sawing machine

- Material: H-beams, I-beams, U-profiles, flat bars, rectangular tubes, square tubes, angles, t-profiles

- Processing Range: Width up to 300 mm

- Processing Capabilities: Drilling, milling, sawing, marking,, thread tapping, counter sinking

- Automation: Fully automated

- Features: Gripper truck, VACAM software, full unmanned operation

VOORTMAN V630

The V630 offers three-axis simultaneous processing with automatic tool changers. It handles web and flange drilling in one pass, reducing labor and increasing throughput. Ideal for compact layouts and high-speed production.

Type:

CNC beam drilling & milling machine

Material:

I/H beams, channels, tubes, flat bar, angle iron

Processing Range:

Width up to 1,140 mm

Processing Capabilities:

Drilling, milling, tapping, countersinking, layout & centerpoint marking

Automation:

3 spindles, 3 x 6-station tool changers, VACAM software

VOORTMAN V631

The V631 delivers the fastest milling in the market with 4,500 rpm and 290 cm³/min removal rate. Each spindle supports 8 tools for full automation. Ideal for high-volume fabricators needing speed and precision.

Type:

CNC beam drilling & milling machine

Material:

Structural steel profiles

Processing Range:

Width up to 1,250 mm

Processing Capabilities:

Drilling, milling, countersinking, thread tapping, layout marking, weld preps

Automation:

3 spindles, 3 x 8-station tool changers, VACAM software

VOORTMAN V633

The V633 is the fastest in the industry for multi-side processing. With servo-driven sub-axes and 5,000 rpm, it delivers unmatched throughput. Ideal for large-scale, automated steel fabrication lines.

Type:

CNC beam drilling & milling machine

Material:

Structural steel profiles, including small profiles

Processing Range:

Width up to 1,140 mm

Processing Capabilities:

Simultaneous drilling, milling, tapping, layout marking, weld preps

Automation:

3 spindles, 3 x 14-station tool changers, 4 sub-axes, VACAM software

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.