CNC PLASMA CUTTING MACHINES, PROFILERS & TABLES FOR HIGH-SPEED STEEL PLATE CUTTING AND DRILLING

Looking for a high-output CNC plasma cutting machine for structural steel fabrication and heavy plate processing?

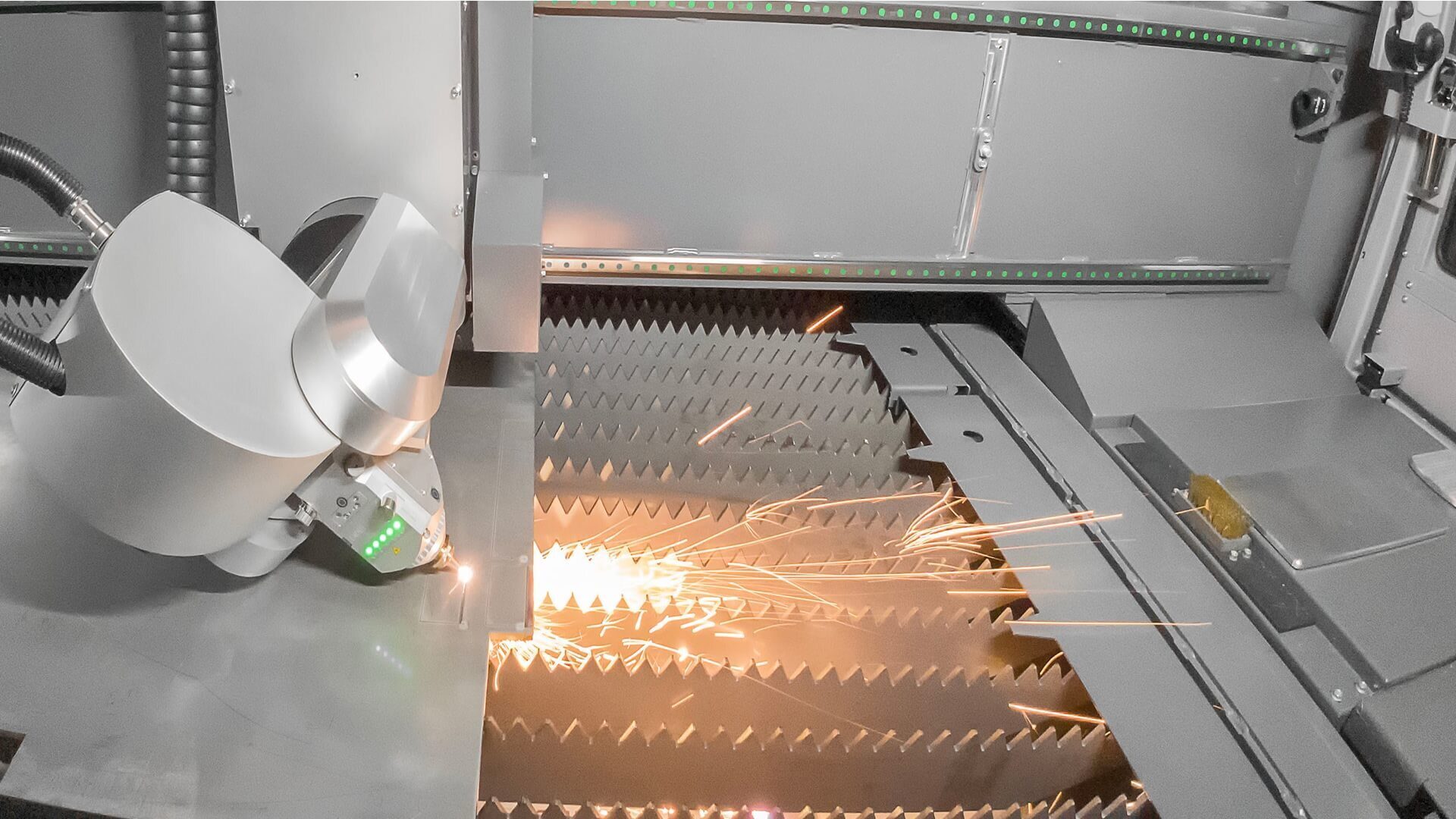

Voortman offers a complete range of plasma and oxy-fuel processing solutions, from automated pass-through plasma tables to flexible moving gantry plasma profilers. Our plate processing machines are engineered to deliver superior speed and unparalleled cut quality, using the industry-leading Hypertherm XPR plasma power source. Voortman machines deliver reliable, high-speed performance for demanding production environments, supporting beveling, heavy drilling, and continuous unmanned processing with automated part removal.

REQUEST MORE INFO EXPLORE MACHINES

PLATE MOVING GANTRY PLASMA MACHINES

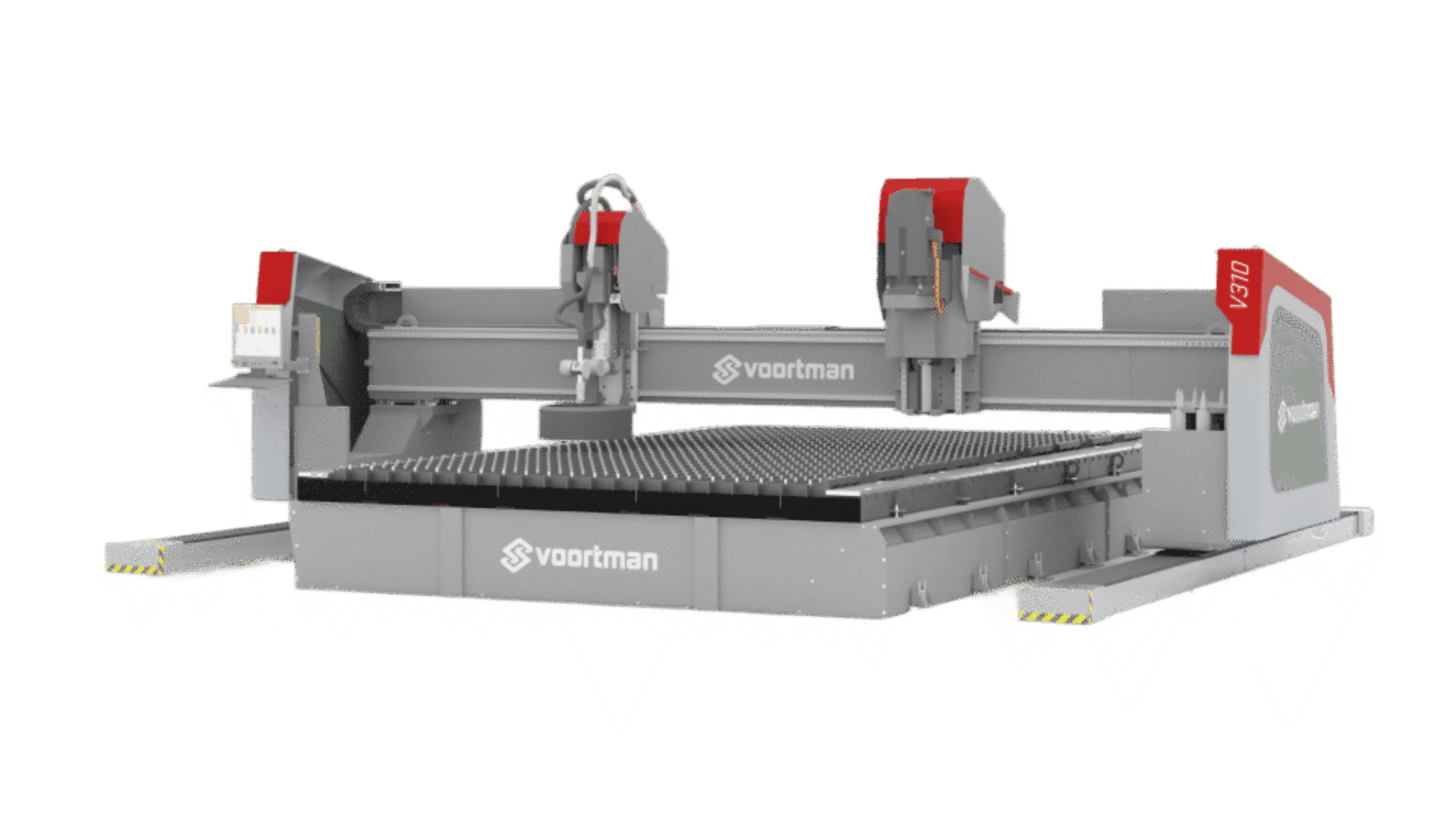

VOORTMAN V310: ALL IN ONE MACHINE

The Voortman V310 is an all-in-one plate processing machine designed for a "Just-In-Time" manufacturing approach. This heavy-duty machine performs 3D bevel plasma or oxy-fuel cutting, carbide drilling up to ϕ40 mm, milling, and tapping all in one sequence. A 10-station automatic tool changer (SK40 spindle) and a heavy steel bridge allow for seamless, high-speed, unmanned processing of thick material. Integration with Voortman software enables a faster flow from model to machine instructions, and extends unmanned operations, delivering unmatched flexibility and lowering your cost per part.

- Type: Moving-gantry plate processing machine

- Material: Steel plates, mild steel plates, stainless steel plates, aluminum plates

- Processing range: Up to 200 mm thick

- Processing capabilities: Plasma, oxy-fuel, 3D Bevel, carbide drilling, milling, tapping.

- Automation: Fully automated processing

- Features: VACAM scheduling/buffering, unmanned running, instant cut, 10-fold auto tool changer

VOORTMAN V303: SINGLE TORCH CUTTING

The Voortman V303 is a flexible gantry CNC plasma and oxy-fuel cutting machine built for high efficiency and minimal operator input. With Instant Cut Technology and the fastest height control on the market, it drastically reduces idle time to double your production capabilities. It delivers superior part quality thanks to features like I-Cut correction. Its robust design allows for operations on plates up to 200 mm, ensuring you get the highest output with reduced part production times and optimized workflow.

- Type: Moving-gantry plate processing machine

- Material: Steel plates, mild steel plates, stainless steel plates, aluminum plates

- Torches: 1

- Processing range: Up to 200 mm thick

- Processing capabilities: Plasma, Oxy-fuel, Bevel Cutting, Marking.

- Automation: Fully autonomous

- Features: VACAM control, Instant Cut, Unmanned running (Scheduling/Buffering).

MULTI-TORCH PLASMA CUTTING MACHINES

VOORTMAN V304: MULTI-TORCH CUTTING

The Voortman V304 is a flexible multi-torch gantry CNC plasma and oxy-fuel cutting machine built for high efficiency and minimal operator input. With Instant Cut Technology and the fastest height control on the market, it drastically reduces idle time to double your production capabilities. It delivers superior part quality thanks to features like Xtensive Bevel Cutting and I-Cut correction. Its robust design allows for multi-torch operations on plates up to 200 mm, ensuring you get the highest output with reduced part production times and optimized workflow.

- Type: Moving-gantry plate processing machine

- Material: Steel plates, mild steel plates, stainless steel plates, aluminum plates

- Torches: Up to 6

- Processing range: Up to 200 mm thick

- Processing capabilities: Plasma, Oxy-fuel, Bevel Cutting, Marking.

- Automation: Fully autonomous

- Features: VACAM control, Xtensive Bevel Cutting, Instant Cut, Unmanned running (Scheduling/Buffering).

PASSTHROUGH PLATE PROCESSING MACHINES

VOORTMAN V320: AUTOMATED PROCESSING

The Voortman V320 is a pass-through plate processing machine engineered for non-stop automation. The machine is equipped with plasma and oxy-fuel cutting technology, coupled with a robust drilling unit (SK40 spindle, 10-tool changer), focusing heavily on continuous material flow. Its flagship feature is the automatic part removal conveyor and drop-door table, which autonomously unloads finished parts (up to 500×500 mm). This pass-through design, supported by a superior gripper system, minimizes dead zones and allows for hours of unmanned production, significantly boosting your throughput.

- Type: Pass-through plate processing machine

- Material: Steel plates, mild steel plates, stainless steel plates, aluminum plates

- Processing range: Up to 75 mm thick

- Processing capabilities: Plasma, oxy-fuel, drilling, tapping, milling, marking.

- Automation: Fully autonomous

- Features: Continuous Workflow, automated Part Unloading (small parts), integrated swarf Brush, unmanned operation.

VOORTMAN V325: HEAVY-DUTY APPLICATIONS

The Voortman V325 is a heavy-duty pass-through plate processing machine designed for processing the thickest steel plate. It features an SK50/CAT50 high-torque spindle (610 Nm) for effortlessly drilling holes up to ϕ70 mm and extended milling capabilities on plates up to 100 mm. The machine includes 3D plasma bevel and oxy-fuel 4.0 cutting for high-quality weld preparations. Automation is maximized with a 20-tool changer, automatic part removal, and an integrated automatic underside deburring unit that reduces secondary operations by up to 30%. This machine delivers powerful, precise, and completely streamlined production of weld-ready heavy-duty parts.

- Type: Pass-through plate processing machine

- Material: Steel plates, mild steel plates, stainless steel plates, aluminum plates

- Processing range: Up to 100 mm thick

- Processing capabilities: Plasma Bevel, oxy-fuel, heavy drilling, enhanced milling, automatic deburring.

- Automation: Fully autonomous

- Features: SK50/CAT50 spindle, automatic part removal/deburring, minimal operator intervention and instant cut.

PASS-THROUGH VS. MOVING GANTRY PLASMA PLATE PROCESSING

Choosing the right machine style is crucial for optimizing your fabrication workflow. The two primary designs are the pass-through system and the moving gantry system. Voortman Steel Machinery offers specialized machines in both categories, such as the V320/V325 (pass-through) and the V303/V304/V310 (moving gantry), each optimized for different production demands. Your choice dictates workflow, material handling requirements, and overall throughput. Understanding the differences is essential to maximize your part production and minimize lead times.

PASS-THROUGH MACHINE

VOORTMAN V320, V325

- Non-stop, highly automated production. Continuous material flow, material is pulled through the machine.

- Best for high-volume production of small to medium parts. Unmanned operation is maximized by automatic unloading.

- Unmanned Running is the key advantage with automatic part removal conveyor. Significantly reduces manual intervention and crane time.

- Minimal material handling required; automatic unloading of finished parts.

MOVING GANTRY MACHINES

VOORTMAN V303, V304, V310

- Flexible work zone and workflow. Plate remains stationary; gantry moves along the plate.

- Best for complex, large parts or multi-process jobs (e.g., drilling, beveling) where the plate must be firmly fixed.

- Processing flexibility as a key advantage. Optimal for single-plate processing and easily integrating multiple heavy tools like drills and advanced bevel units.

- Requires crane for loading and unloading the entire plate.

SELECT YOUR IDEAL PLATE CUTTING SOLUTION

Select a pass-through plate processing machine like the V320/V325 for non-stop, unmanned cutting and drilling with automatic part removal. Choose a moving gantry plate cutting machine like the V304/V310 for maximum processing flexibility, heavy-duty drilling, and handling very large or extra-thick plates.

HYPERTHERM XPR SERIES: NEXT-GENERATION X-DEFINITION PLASMA

The Hypertherm XPR plasma power source is the industry standard for achieving superior cut quality, reduced operating costs, and enhanced speed in plate fabrication. Voortman CNC plate processing machines, including the V303, V304, V310, V320, and V325, are engineered to maximize the performance of the Hypertherm XPR series.

X-DEFINITION CUT QUALITY

The XPR series delivers a new level of cut precision on mild steel, stainless steel, and aluminum, surpassing previous high-definition plasma. This results in smoother surface finishes, sharper edges, and improved hole cylindricity, often meeting or exceeding ISO range 2 and 3 standards.

LOWER OPERATING COSTS

Advanced arc response technology and features like PowerPierce ensure dramatic improvements in consumable life, sometimes triple that of previous systems. This reduces downtime and slashes your overall cost per part by up to 50% in many applications.

ENHANED PRODUCTIVITY

The XPR system, including models like the XPR300, provides faster cutting speeds and thicker piercing capabilities, allowing your machine to handle heavier plates with higher efficiency. Features like True Hole technology guarantees excellent bolt-ready hole quality automatically.

PLASMA VS. LASER CUTTING: CHOOSING THE RIGHT TECHNOLOGY

The choice between plasma and fiber laser hinges on material thickness, required precision, and budget. While plasma remains the workhorse for heavy steel, advanced fiber laser systems, such as the Voortman V342 (entry-level) and V353 (XXL heavy-duty), have significantly expanded laser capability for thick plate and bevel cutting.

PLASMA CUTTING

VOORTMAN V303, V304, V310, V320, V325

- Excels on different material thicknesses: thick and very thick material (∼6 mm up to 100 mm). Faster and more cost-effective on plates over 1/2 inch (12 mm).

- Very good quality and superior precision, suitable for structural steel. Can achieve bolt-ready holes. Higher kerf and heat affected zone (HAZ).

- Fastest cutting speed on thick steel

- Lower initial purchase cost for the machine and power source.

FIBER LASER CUTTING

VOORTMAN V342, V353

- Excels on thinner material. New high-power systems (e.g., 40 kW) now cut up to 75 mm.

- Superior precision and edge quality, minimal HAZ. Ideal for intricate designs and tight tolerances (<±0.1 mm). Excellent beveling (e.g., V353 cuts A-, V-, X-, K-, Y-bevels).

- Fastest cutting speed on thin steel (e.g., V353 15kW is 3.5× faster than plasma on 12mm mild steel).

- Higher initial investment cost (e.g., for high-wattage V353).

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.