WIR ENTWICKELN HIGH-END-STAHLBEARBEITUNGSMASCHINEN MIT INTEGRIERTER BETRIEBSSOFTWARE, DIE IHREN PRODUKTIONSPROZESS AUTOMATISIEREN UND OPTIMIEREN.

MIT DEM BESTEN KUNDENSERVICE

VOORTMAN IN ZAHLEN

WER WIR SIND

Willkommen bei Voortman Steel Machinery, einem Namen, der für Innovation, Exzellenz und ein starkes Engagement für Qualität steht. Wir haben uns von bescheidenen Anfängen zu einem großen, weltweit führenden Unternehmen entwickelt, das unvergleichliche CNC-Stahlbearbeitungsmaschinen mit integrierten Business-Software-Lösungen herstellt, die Ihren Produktionsprozess automatisieren und optimieren.

WAS UNS ANTRIEBT

Das ist ganz einfach: Ihre Bedürfnisse und deren Übertreffen. Unsere Mission geht über die Maschine hinaus; wir entwickeln komplette Lösungen. Und wir tun dies mit dem Versprechen des besten Kundendienstes, wobei wir jedes Projekt und jeden Kunden als Teil unserer erweiterten Voortman-Familie behandeln.

WIE ALLES BEGANN

"Es ist mir ein Privileg, die Geschichte unseres Unternehmens zu erzählen, eine Reise, die mir sehr am Herzen liegt und mit unserem Familienunternehmen verwoben ist. Alles begann in einem bescheidenen Hühnerstall in den Niederlanden im Jahr 1968. Die Vision und die harte Arbeit meines Vaters legten den Grundstein für das, was Voortman heute ist.

Diese Anfänge waren geprägt von Pioniergeist und Innovation. Zunächst konzentrierten wir uns auf den Bau von Stahlkonstruktionen, ein Unterfangen, das nicht nur Können, sondern auch eine Vision für die Zukunft erforderte. In den 1995er Jahren wuchsen unsere Ambitionen und wir begannen mit der Entwicklung von Stahlbearbeitungsmaschinen - ein bedeutender Schritt, der den Beginn eines neuen Kapitels markierte: Voortman Steel Machinery.

Im Laufe der Jahre hat sich unser Unternehmen zu einem weltweit führenden Hersteller von CNC-Stahlbearbeitungsmaschinen und Softwarelösungen für die verschiedensten Branchen entwickelt. Ich bin stolz darauf, sagen zu können, dass wir weltweit zahllose Maschinen installiert haben. Unsere Reise, die von Meilensteinen und Partnerschaften geprägt ist, wäre ohne unsere geschätzten Kunden und talentierten Mitarbeiter nicht möglich gewesen. Ihr Engagement, ihr Fachwissen und ihre Leidenschaft waren bei jedem Schritt unseres Fortschritts ausschlaggebend.

Ich lade Sie ein, die Schlüsselmomente unserer Reise zu entdecken, die nicht nur Errungenschaften sind, sondern auch das Vertrauen und die Beziehungen darstellen, die wir mit unseren Kunden und Partnern aufgebaut haben.

Vielen Dank, dass Sie Teil unserer Geschichte sind oder sie gerade erst zu entdecken beginnen!"

WIE WIR ES MACHEN

Maschinen + Software + Service = Ihr Partner für Gesamtlösungen

Unser Ziel ist es, Ihr Komplettanbieter zu sein - ein Partner, der nicht nur Geräte liefert, sondern eine komplette Lösung für Ihre Branche. Im Laufe der Zeit haben wir uns nicht nur zu einem Maschinenhersteller entwickelt, sondern auch zu einem Architekten von Softwarelösungen. Wir wissen, dass Software im Geflecht der modernen Produktion nicht nur ein Faden, sondern eine wichtige Lebensader ist. Sie ist der Schlüssel, um das volle Potenzial Ihres Produktionsprozesses zu erschließen und jeden Schritt bis zur Perfektion zu optimieren.

Stellen Sie sich eine Situation vor, in der jede Profil-, Rohr- und Blechbearbeitungsmaschine Teil eines größeren, intelligenteren Systems ist. Das ist es, was wir mit unserer fortschrittlichen VACAM Software und der umfassenden LogicSteel Software Suite schaffen. Es geht darum, ein Ökosystem zu schaffen, das intuitiv, effizient und nahtlos verbunden ist.

Und wir beschränken uns nicht nur auf die Bereitstellung modernster Maschinen und Software. Zu unserem Engagement für Sie gehört auch ein leistungsstarker, lokaler Kundendienst. Wir sind der Meinung, dass der Support ebenso zugänglich wie effizient sein sollte. Egal, wo Sie sich befinden, wir sind nur einen Anruf oder einen Klick entfernt. Wir wollen es Ihnen leicht machen und dafür sorgen, dass Sie von dem Moment an, in dem Sie mit uns zusammenarbeiten, keine Sorgen mehr haben.

Sie können von unserem internen Ansatz profitieren

Im Mittelpunkt unseres Ethos steht eine Mischung aus zukunftsorientierter Innovation, Engagement für die Automatisierung und einem unermüdlichen Fokus auf Qualität. Es ist nicht nur das, was wir tun, sondern auch die Art und Weise, wie wir es tun, die uns auszeichnet. Wir glauben fest daran, dass die Verlagerung von Prozessen ins Haus der Schlüssel zu Effizienz, Unabhängigkeit und gleichbleibend hoher Qualität ist.

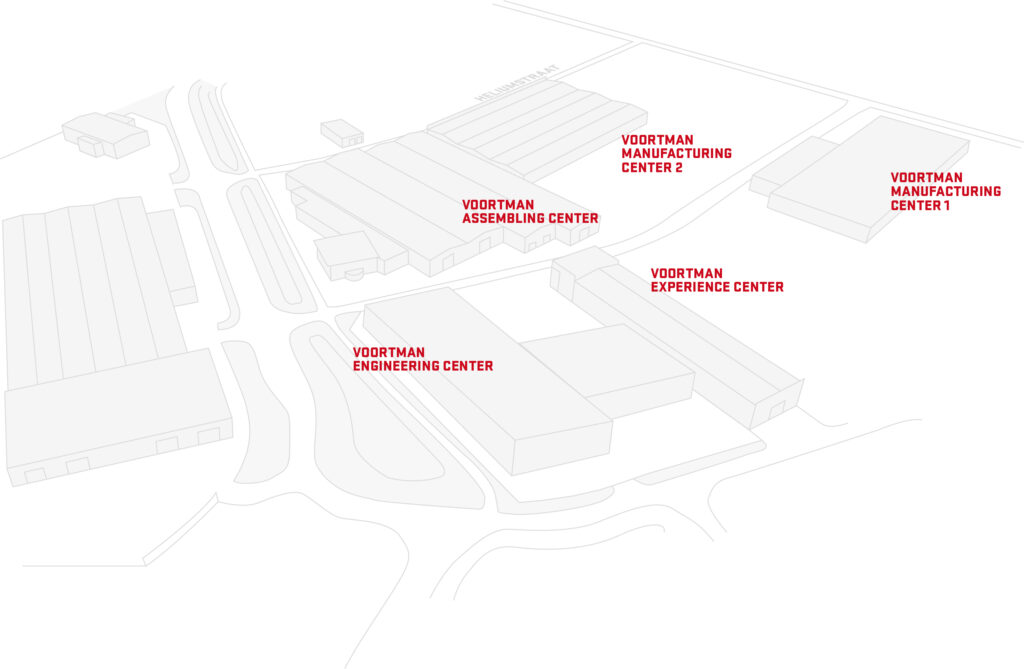

Jedes Gebäude auf unserem großen Voortman-Campus spiegelt sich ein einzigartiger Aspekt unserer internen Philosophie wider. Angefangen bei der eigenen Montage und gründlichen Prüfung bis hin zur eigenen Produktion der robusten Maschinengestelle und -schränke. Wir haben alles unter Kontrolle, damit Sie sicher sein können, dass Sie ein erstklassiges Qualitätsprodukt erhalten!

Und das Beste daran? Wir freuen uns darauf, diese Welt mit Ihnen zu teilen. Begleiten Sie uns auf einen Rundgang durch unsere Gebäude. Wir ziehen den Vorhang zurück und zeigen Ihnen, was hinter diesen Mauern geschieht, damit Sie aus erster Hand sehen können, mit welcher Sorgfalt, Fachkenntnis und Leidenschaft wir jede unserer Lösungen entwickeln.

Erleben Sie den Voortman Campus / Ein Exklusiver Blick Hinter die Kulissen

ㅤ

https://youtu.be/PYVLlZ5vyPU?s...

Voortman Experience Center

Interaktiver Ausstellungraum, Demo- und Schulungszentrum

https://youtu.be/BgAGCwgbqbc?s...

Voortman Assembling Center

Zusammenbauen – testen – transportieren

https://youtu.be/R4j-3L-FJHw?s...

Voortman Manufacturing Center 1

Nutzen Sie unsere Maschinen, um unsere Maschinen zu bauen

https://youtu.be/UGQ17A5FunE?s...

Voortman Manufacturing Center 2

Zusammenschweißen von Teilen und Herstellung von Schaltschränken

Interaktiver Austellungsraum, Vorführ- und Schulungszentrum

Besuchen Sie das Voortman Experience Center

Wir laden Sie herzlich in unser Voortman Experience Center ein - ein Raum, der mehr ist als nur ein Ausstellungsraum, er ist ein interaktives Abenteuer. Erkunden Sie unsere Maschinen aus der Nähe, wählen Sie eine aus, die Sie interessiert, und wir arrangieren eine Live-Demonstration nur für Sie. Erleben Sie aus erster Hand, wie unsere Maschinen Rohmaterialien in Meisterwerke verwandeln. Sie können uns nicht persönlich besuchen? Kein Problem! Erleben Sie es online.

DIE REISE VON VOORTMAN GEHT WEITER, IHRE?

Mit Blick auf die Zukunft sind wir gespannt auf die Möglichkeiten, die vor uns liegen. Wir bleiben unserem Auftrag treu, unseren Kunden einen außergewöhnlichen Wert zu bieten und eine wichtige Rolle bei der Weiterentwicklung der stahlbearbeitenden Industrie zu spielen. Wir werden auch weiterhin innovativ sein, wachsen und einen nachhaltigen Einfluss auf die Welt ausüben.

Aber hier ist eine Frage an Sie: Was sind Ihre Pläne für die kommenden 10 Jahre?

Warum auf Inspiration warten, wanne man sie je?

Wir helfen Ihnen, sie zu entdecken.

BLEIBEN SIE IN VERBINDUNG, BLEIBEN SIE INSPIRIERT!

Warum folgen Sie uns nicht für weitere spannende Inhalte und Updates?

Sind Sie bereit, Teil unserer interessanten Reise zu werden? Verbinden Sie sich mit uns auf unseren sozialen Kanälen oder über unseren Voortman-Newsletter und bleiben Sie auf dem Laufenden über alle unsere neuesten Abenteuer, Innovationen und Geschichten!

Unser monatlicher Newsletter ist Ihr persönlicher Zugang zu einer Welt voller spannender Entwicklungen und exklusiver Einblicke. Wenn Sie sich anmelden, sind Sie nicht nur an der Spitze der Branchentrends, sondern auch Teil einer Gemeinschaft, die Wert darauf legt, informiert zu bleiben und der Zeit voraus zu sein. Lassen Sie sich diese Gelegenheit, Ihr Wissen zu erweitern, nicht entgehen. Melden Sie sich noch heute für unseren Newsletter an und erhalten Sie jeden Monat eine Dosis an Inspiration und Einblicken!