Voortman V704

Four side beam layout marking

Layout marking is a bottleneck in many operations. The Voortman V704 beam layout marking machine improves efficiency and accuracy and leaves the days of layout marking bottlenecks behind. In a fully automated production line, the V704 increases output by offloading other machines that can also mark. It can be added to a production line to mark as much as possible automatically, making assembly and welding easier and faster with no chance of error.

Increased productivity and improved accuracy

FOUR SIDE LAYOUT MARKING

The Voortman V704 marks all four sides of the product in one pass, saving time and costs in the assembly area of your workshop. When marking only one side, assembly employees still need to perform manual measurements on the remaining sides of the profile. The machine can indicate product numbers, contours, welding information and detailed part numbers for plates and angles that will be welded to the profile. The marking tool has minimal maintenance required because the tool is driven by compressed air. Carbide tips are quick and easy to replace.

ACCURATE POSITIONING

Every profile and product is measured, and the position is tracked and maintained throughout processing with the roller feed measurement system in the V704. Marks are placed in exactly the right position as determined in the DSTV file or the file in VACAM software. When integrated in a complete production line, all processes are split up between capable machines in the system and positioned correctly, so the combined product is exactly according to the product description. Measuring is faster and more precise with the V704 than the manual process.

High quality processing & marks

Robust & high quality machine

MARKS VISIBLE AFTER BLASTING AND PAINTING

The Voortman V704 layout marking machines creates high quality, accurate and clearly visible marks with one of its multiple scribing tools. Marking by milling is beneficial because the marks remain visible even after shotblasting, painting or galvanizing. Products are easily recognizable in downstream production steps, and welders don’t need to make any additional marks before continuing. Marking depth can be adjusted with the Voortman marking tool.

HIGH QUALITY MARKS

The V704 is a robust machine made with high-quality components, enabling you to carry out processes with impressive stability. This results in lower tolerances and higher quality layout marks and finished products. Voortman uses well-known established brands like Siemens and Bosch. Components are industry-standard and made to have a long lifetime, but if they break down spare parts are widely available from Voortman.

Reduce labor costs and increase efficiency

The V704 can be integrated in a "split configuration" where a beam drilling and sawing machine are fully dedicated to drilling and sawing your profiles, while the V704 simultaneously focuses on creating layout markings on the cut and drilled profiles while a new batch of profiles is being processed by the drilling and sawing machine again.

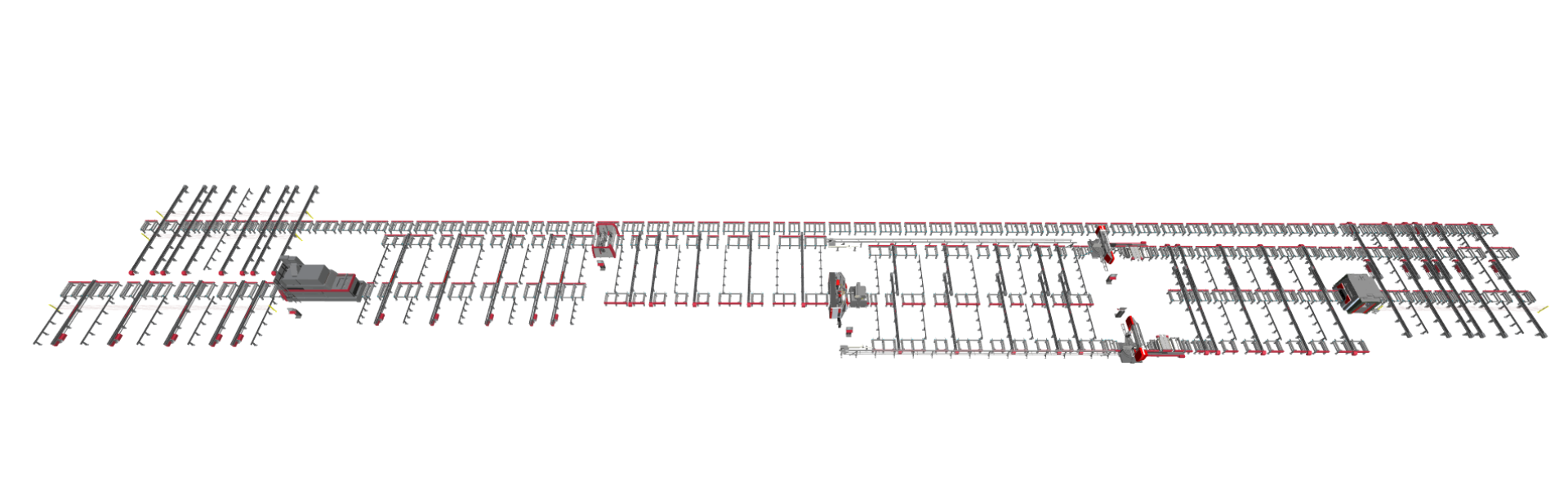

MSI, also referred to as Multi System Integration, opens the door to fully automate your production by connecting machines with cross transports, roller conveyors, product buffers, and material sensors. Production data only needs to be imported once and then MSI automatically distributes the data to all machines integrated in your production system.

VACAM decides optimal material route

Based on the production on hand, customer preferences and the available machinery in the MSI-line, VACAM automatically decides the optimal route to reach the highest efficiency. MSI designates the end of transporting raw profiles and semi-finished products from machine to machine. MSI stands for one integrated production system. You can track and monitor every profile, product and future planning in real time by using VACAM, Voortman’s proprietary CNC control software installed on every machine.

Designing your optimal layout

Together with you, the Voortman team designs the entire layout based on your current or expected production characteristics, such as type of profiles, product length, number of processes, hours in your work week and budget.