Voortman VB Range

Beam sawing

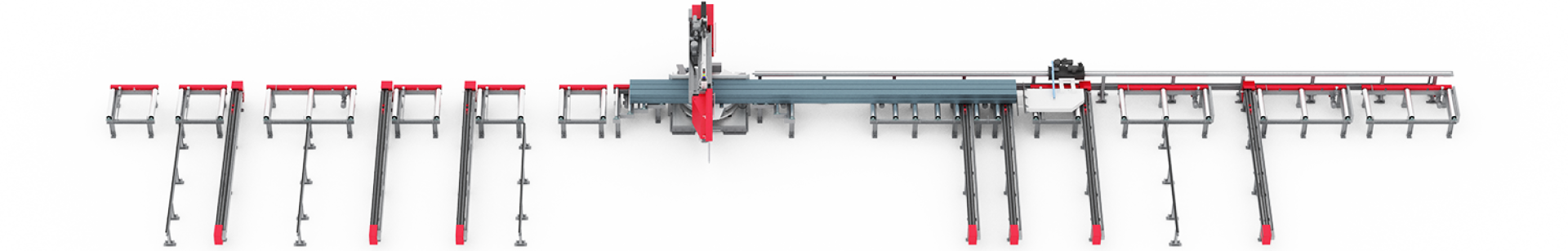

The Voortman VB Range CNC bandsaw machine is designed to provide automated straight and miter cutting for structural steel. Each machine is mounted to a heavy-duty frame and comes equipped with the latest technology in servo motors and ball screw spindles. The VB Range cuts with optimal speed and quality for maximum production throughput.

High stability sawing and long lifetime

HIGH STABILITY SAWING AND LONG LIFETIME

VB Range bandsaw machines have a welded base frame for maximum stability. This ensure that the saw always has the desired tension and doesn’t deviate from the intended saw line. The machine can process at a consistent, higher pressure supported by the robust frame.

Several features included in the machine extend the lifetime of bandsaw blades. A swarf brush removes chips from pockets in the saw blade and supports maximum saw band speeds for the best results. The VB Range also has a maximum force limit ensuring the saw always pushes with optimal force for exact cutting functionality.

Complete automation, no matter how small the product

COMPLETE AUTOMATION, NO MATTER HOW SMALL THE PRODUCT

The VB Range is capable of autonomous production when even the smallest products are being produced. Clean, small cuts can be removed with the Short Product Removal System (SPRS), while profiles weighing many tons or outputting at long lengths can easily be sorted onto different sections of roller conveyors and cross transports at the outfeed. The flexibility and automation allows the operator’s role to focus on loading and unloading the system, saving valuable time and labor costs.

Integration in your workshop

Combined sawing and drilling with measuring rolls

The fastest measuring and transportation system for profiles in the market

The Voortman roller feed measuring system uses two feeder rolls to move material. Two measurement wheels are installed to accurately track the profile's position. Feeder rolls are often used because of the required space and the flexibility when integrated into a larger system. With a measuring roll system, it is also possible to load a new profile once the first profile has passed the edge of the cross transports.

Since a feeder roll does not have a rail, it is possible to feed into the machine from two sides. With Voortman, you have a choice in measurement systems, making it possible to tailor the system to the characteristics of your production database.

Combined sawing and drilling with feeder truck and SPRS

A strong and robust servo driven gripper truck for processing many small products

Voortman also offers a strong and robust servo driven gripper truck. This truck is the fastest truck available, adapting its velocity dynamically to the profile's total weight. This makes the truck more agile and safe for the operator. The feeder truck holds the material with a wide clamp, which is rotated automatically when the geometry of the profile demands. This measuring system is capable of moving even the heaviest profiles without losing its stability.

The gripper truck can be combined with the VB beam sawing machine - often with an automatic Short Product Removal System (SPRS) where the gripper clamps all products up to 1.400 mm (4-1/2'). during cutting, and then short products are transported sideways. With the SPRS and the gripper truck, the drill and saw become fully autonomous with clean cuts automatically dropped into a separate bin. Just start your latest production run before you close the factory for the night and arrive in the morning with all products processed and sorted on the outfeed cross transports.

Full stop measuring system | Bundle sawing

A very powerful option, excellent for bundle sawing

The full stop measuring system with a Voortman Band saw is a very powerful option that is excellent for bundle cutting. Profiles are transported to the full stop truck individually or as bundle. When profiles are clamped, to be sawed to length, the full stop truck automatically moves to the next position. This way, the full stop truck ensures a high output. The full stop truck can also be used for individual profiles, and when a profile is still in the saw, the next profile can be loaded onto the infeed roller conveyor.

It is also possible to apply the VB Band saw with full stop measuring system in a fully automated integrated production system, also referred to as a MSI system, taking the best from both worlds: High speed bundle sawing and fully automated steel processing.

| https://youtu.be/TyDy13pwuNY |

Combination with bundle clamp and bundle stop

If you need even more control when sawing bundles, you can combine a full stop measuring system with a bundle clamp and bundle stop. The bundle stop is placed in front of a bundle of profiles, so that profiles are aligned. With the bundle clamp, profiles can be clamped from the top, so that they are secured before and during sawing.

Full automation in a modular split system

Reduce laber costs and increase efficiency

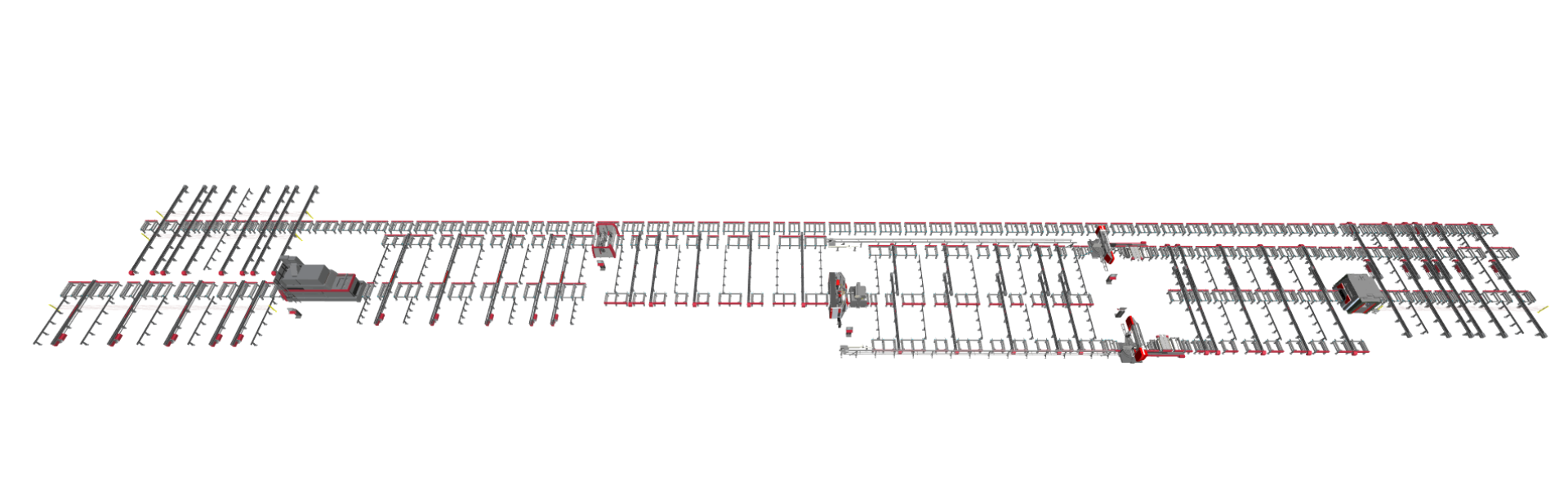

MSI, also referred to as Multi System Integration, opens the door to fully automate your production by connecting machines with cross transports, roller conveyors, product buffers, and material sensors. Production data only needs to be imported once and then MSI automatically distributes the data to all machines integrated in your production system.

VACAM decides optimal material route

Based on the production on hand, customer preferences and the available machinery in the MSI-line, VACAM automatically decides the optimal route to reach the highest efficiency. MSI designates the end of transporting raw profiles and semi-finished products from machine to machine. MSI stands for one integrated production system. You can track and monitor every profile, product and future planning in real time by using VACAM, Voortman’s proprietary CNC control software installed on every machine.

Designing your optimal layout

Together with you, the Voortman team designs the entire layout based on your current or expected production characteristics, such as type of profiles, product length, number of processes, hours in your work week and budget.

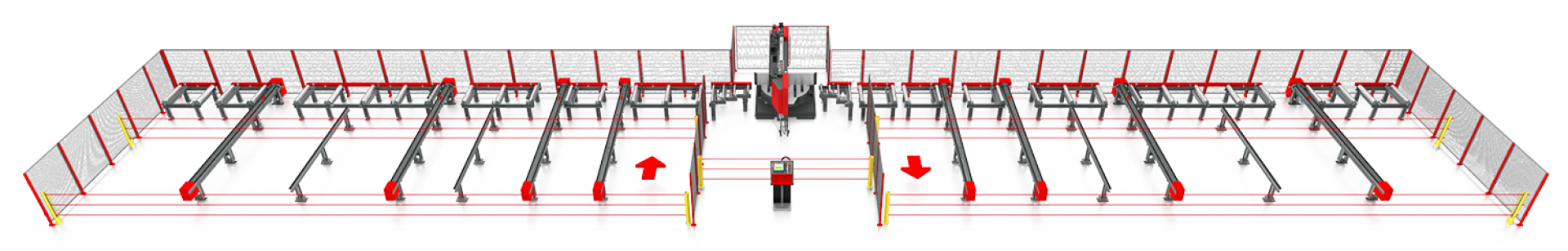

Safety

An integral plan to keep your production line safe and up and running

After installing a machine or production line, Voortman installs a net of safety measures. These safety measures comprise of light curtains, emergency cords and emergency stop buttons. Voortman has made it one of its priorities to deliver a safe production line, yet not hold up production if the operator needs to enter the safe zone. This is accomplished by using gated light curtains allowing loading and unloading while the machines continue processing, and by delivering remote controls with a kill switch that operators can use when carrying out tasks inside the safety zone.

Specifications

| Voortman VB Range | |||

|---|---|---|---|

| Voortman VB1050 | Voortman VB1250 | ||

| Operating range 0° | inch | 20 x 44 | 24 x 50 |

| Operating range 15° | inch | 20 x 41-23/32 | 24 x 47-1/4 |

| Operating range 30° | inch | 20 x 36-13/32 | 24 x 39-13/32 |

| Operating range 45° | inch | 20 x 28 | 24 x 33-1/2 |

| Operating range 60° | inch | 20 x 18-1/2 | 24 x 20 |

| Feed Approach speed | f/min | 20 | 20 |

| Saw band drive | Hp | 10 | 15 |

| Saw band speed | f/min | 130 - 400 | 130 - 400 |

| Saw band size | inch | 2-1/8 x 1/16 | 2-5/8 x 1/16 |

| Saw band inclination | 5° | 5° | |

| Machine weight | lbs | 18,750 | 22,000 |