Voortman V550-7

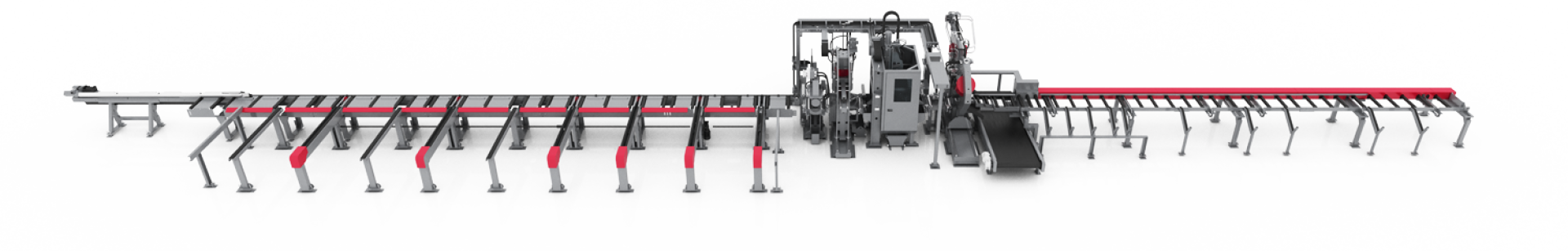

The Voortman V550-7 CNC flat and angle processing machine is built for speed, reliability and versatility in punching, shearing and drilling flat and angle profiles. Capabilities include both horizontal and vertical punching, carbide drilling, thread tapping, countersinking and miter shearing up to 45° in either direction.

Top speed processing

More production without compromising on accuracy

HIGH SPEED PROCESSING

The Voortman V550-7 flat and angle processing machine is more productive than any CNC machine in its range. Production speeds drastically improve with high performance hydraulics and a robust, high speed gripper truck. VACAM control software reduces scrap by automatically optimizing the cutting sequence, checking material length and nesting on the fly. Processes are closely matched to limit the time operators are waiting. Servo-controlled components and the machine’s powerful hydraulic systems optimize production cycles.

Highly automated material handling

EFFICIENT AUTOMATED MATERIAL SORTING

The V550-7 can be equipped with an efficient sorting system to provide more efficient nesting of products from different projects in full flat/angle stock lengths with minimal waste. Products are seamlessly and automatically assigned to one of the 13 sorting bins based on project, phase number, material thickness, etc.

AUTOMATIC MATERIAL BUFFERING - NO MANUAL INTERVENTION

The V550-7 can process flat and angle profiles up to 15 m (50’) without any manual intervention. VACAM control software automatically monitors the active buffer system, securing a priority position for your first profile to be processed while buffering the subsequent profiles. By allowing the system to continuously move profiles towards the roller conveyor and gripper truck, new batches can be loaded and started on the V550-7 in no time. This significantly reduces production times and increases overall efficiency.

Great versatility

Multiple processes and material thicknesses

AUTOMATIC DIE SELECTION AND MULTIPLE PROCESS CAPABILITIES

The V550-7 is equipped with stations for 13 dies in a rotational holder with up to 7 vertical punches. This provides processing capabilities for a wide range of thicknesses without needing additional punch and die changes. The fast and accurate servo-driven carousel is synchronized with the vertical punches for maximum speed punching. The V550-7 also adds drilling function for processes like drilling, thread-tapping, layout marking, part identification and countersinking.

The machine in practice

Time study angle processing

Real-time demo

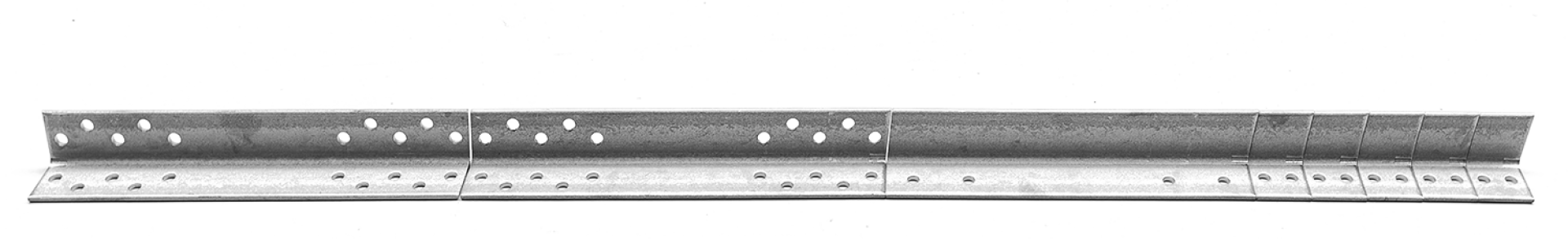

This real-time demo product showcases the high processing speed and quality of the Voortman V550-7 on angle profiles.

Product fabrication time

It took 3 minutes and 1 second to perform all actions in the sample part.

- 10x - 22 mm (7/8") horizontal punched holes

- 34x - 22 mm (7/8") vertical punched holes

- 9x- shear cuts (including 1 trim cut)

Time study flat bar processing

Real-time demo

This real-time demo product showcases the high processing speed and quality of the Voortman V550-7 on flat bar profiles.

Product fabrication time

It took 4 minutes and 16 seconds to perform all actions on this sample part.

- 4x- 18 mm (11/16") drilled holes

- 40x- 18 mm (11/16") punched holes

- 40x- 22 mm (7/8") punched holes

- 6x- 26 mm (1") punched holes

- 4x- 31 mm (1-1/4") punched holes

- 10x- shear cuts (including 4 miter cuts

Safety

After installing a machine or production line, Voortman installs a number of safety measures. These safety measures comprise of light curtains, emergency cords and emergency stop buttons. Gated light curtains allow loading and unloading while the machines continue processing.

Specifications

| Voortman V550-7 | ||

|---|---|---|

| Voortman V550-7 | ||

| Flat steel | inch | 2 x 3/16 - 19-5/8 x 1 |

| Flat steel (45° cut) | inch | 12-1/2 x 1 |

| Angle steel | inch | 2 x 3/16 - 8 x 5/8 |

| Marking | hydraulic numbering (standard) and/or milling (optional tool) | |

| Vertical punches | 7 punches and 13 dies | |

| Vertical punch capacity | tons | 120 |

| Horizontal punches | 1 | |

| Horizontal punch capacity | tons | 77 |

| Drilling units | 1 vertical (option) | 1 |

| Drill diameter | inch | 3/16 - 1-9/16 |

| Thread tapping | M6 - M30 | |

| Tool changer | 1 x 5 | |

| Drill holder | SK40 | |

| Nominal drilling power | Nm | 200 |

| Speed | rpm (stepless) | 0 - 4.500 |

| Shear | flat and angle (option) | |

| Shear capacity | tons | 270 |