AUTOMATED SURFACE TREATMENT MACHINES FOR EFFICIENT STEEL BLASTING & PAINTING

Looking to streamline your steel preparation process?

Voortman’s VSB and VP Ranges offer fully automated shot blasting and painting solutions that deliver clean, primed, and ready-to-process profiles in one seamless flow. Whether you're removing mill scale or applying welding primer, Voortman’s surface treatment line ensures consistent quality with minimal manual handling. Combine blasting and painting back-to-back for unmatched productivity and floor space savings.

REQUEST MORE INFO EXPLORE MACHINES

SURFACE TREATMENT MACHINES

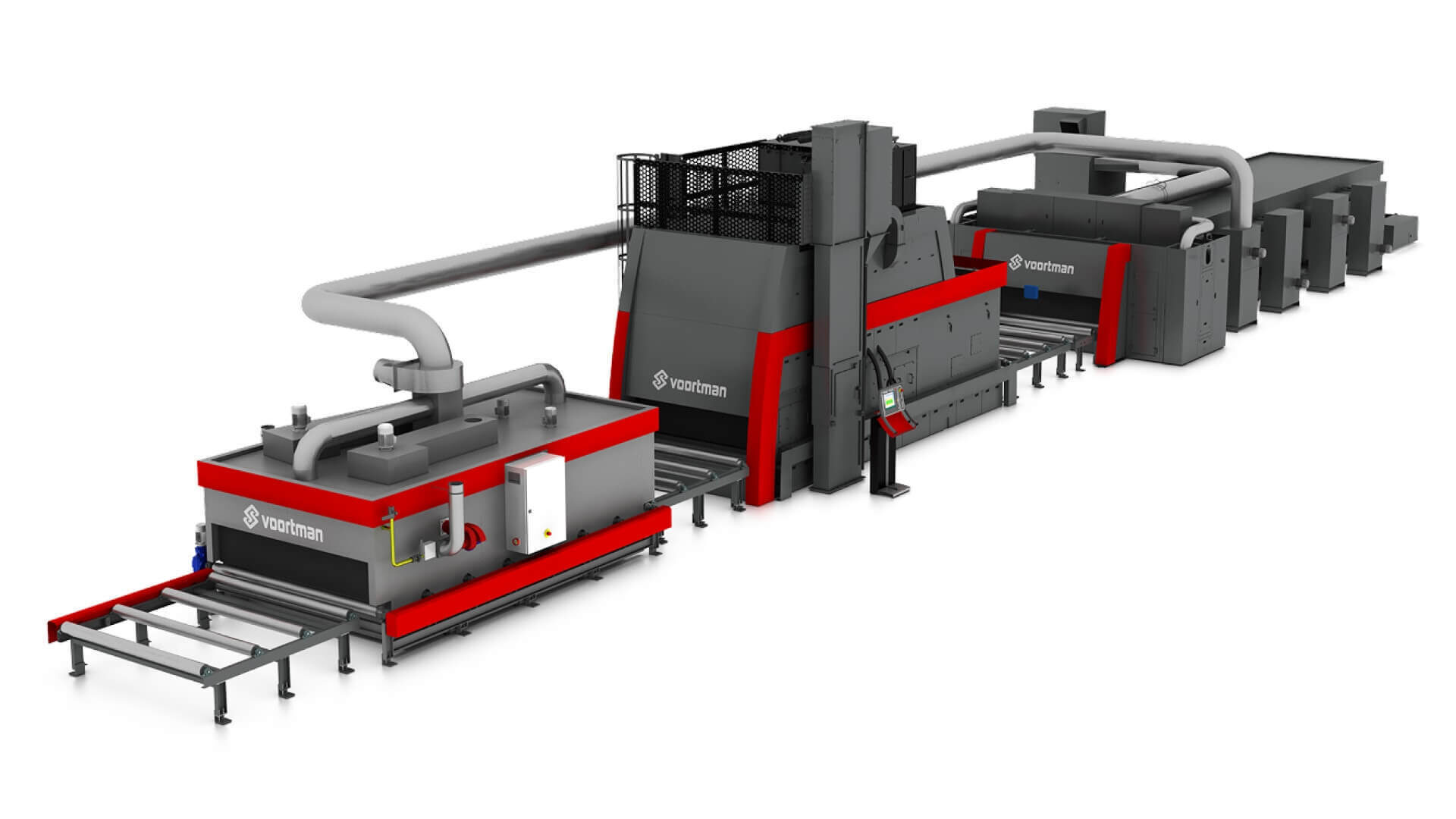

VOORTMAN VSB

The Voortman VSB Range is one of the most automated structural blasters on the market. With frequency-controlled turbines, automatic abrasive management, and intelligent batching, it delivers high-speed, high-quality blasting with minimal operator input. Its compact design allows integration with painting, drying, and pre-heating modules, making it ideal for prefabrication workflows.

- Type: CNC shot blasting machine

- Material: Plates and steel profiles

- Processing capabilities: Mill scale removal, rust cleaning, surface preparation to SA2.5 standard

- Automation: Fully automated

- Features: Automatic batching, brush height adjustment, abrasive refill, and in/outfeed handling

VOORTMAN VP

The Voortman VP Range is a fully automated welding primer machine that paints only when material is present, saving paint and reducing wear. It supports up to three paint types and integrates seamlessly with the VSB Range for a complete surface treatment line. Optional pre-heaters and blow-off units ensure optimal paint adhesion and drying.

- Type: CNC steel painting machine

- Material: Plates and steel profiles

- Processing capabilities: Automatic primer application, multi-color paint systems, solvent- and water-based paint compatibility

- Automation: Fully automated

- Features: Material detection, height adjustment, automatic paint selection, and cleaning systems

FROM BLASTING TO PAINTING; BACK-TO-BACK EFFICIENCY

Imagine blasting and painting steel profiles without moving them between machines. With Voortman’s integrated surface treatment line, your VSB shot blaster and VP painting machine work as one unit. This system provides one measurement for two processes, allowing you to blast and paint in a single flow. This results in a highly compact footprint, saving valuable floor space, and reduced handling by eliminating extra crane moves and wasted time. This integrated configuration is perfect for workshops that want speed, consistency, and automation without expanding their layout.

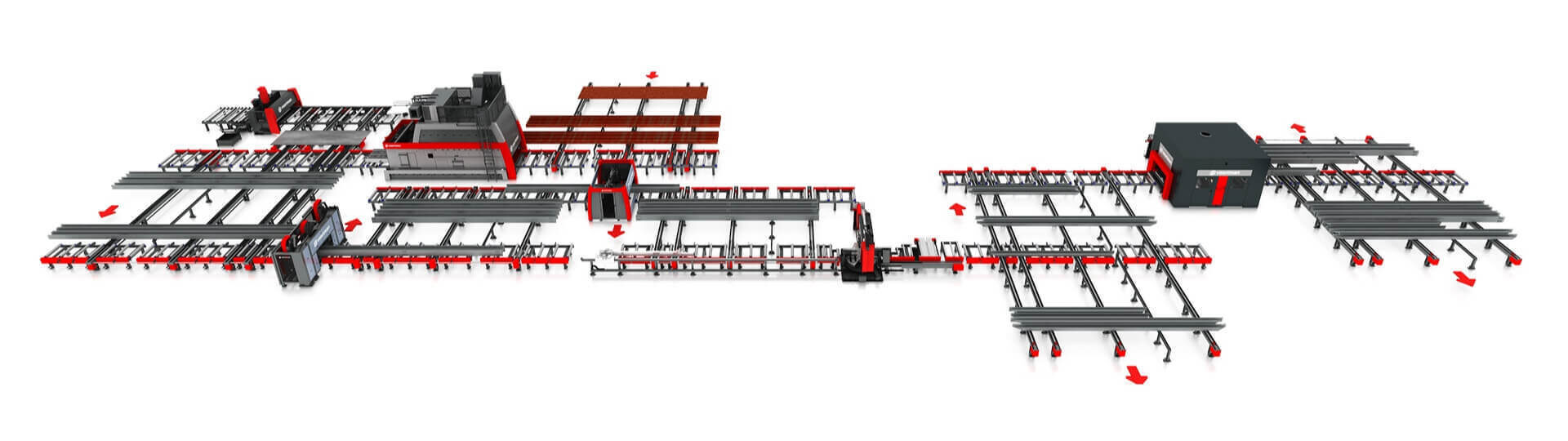

SMART FACTORIES MADE SIMPLE WITH MULTI SYSTEM INTEGRATION

For steel fabricators and distributors seeking full automation, Voortman’s Multi System Integration (MSI) offers a comprehensive solution. It seamlessly connects machines such as blasters, painters, saws, and drills through conveyors and buffer zones, enabling smooth material flow with minimal manual intervention. Powered by VACAM intelligence, the system continuously optimizes production in real time across all integrated components, eliminating bottlenecks. Additionally, LogicSteel MRP enhances operational efficiency by managing planning, scheduling, and reporting from 3D model to final delivery, all within a single platform.

MSI turns your surface treatment line into a smart, high-output system, reducing manhours per ton and delivering consistent, high-quality results.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.