Voortman V631

High speed beam drilling and milling

The Voortman V631 adds increased milling capabilities to its proven automated beam drilling machines. With its impressive milling capabilities and the ability to simultaneously drill and mark all sides, the V631 provides high speed processing to accelerate your production.

Fastest milling & high productivity

FASTEST MILLING IN THE MARKET

The V631 can boast the fastest milling in the market with using shorter tool lengths, which reduce the distance between the drill and the profile. The shorter the tools, the faster the drill units can move through the material and the longer your consumables will last. Robust bearing and securely mounting the drill units onto the heavy duty frame also helps improve milling speed and quality.

SIMULTANEOUS PROCESSING

The V631 drilling and milling machine can process both flanges and the web at the same time, greatly reducing labor hours and operating costs in your workshop. Each of the three drill heads has its own automatic toolchanger with stations for up to 8 tools each, increasing automatic processing capabilities for a wide range of processes. Voortman’s VACAM operating software optimizes the tool changing and sorting operation sequence, increasing output efficiency.

High quality processing

ROBUST MACHINE

The V631 is a beast of a machine with a very sturdy frame. It’s made with premium high-quality components improving its stability and accuracy. Tolerances can be smaller and product quality can improve based on the stability of the machine. Components are sourced from well-known established brands like Rexroth, Siemens and Festo. Components have a long lifetime and spare parts are available at strategic, globally-placed warehouses.

HIGH PRECISION CARBIDE DRILLING & MILLING

The V631’s motor provides a higher rotational speed, reaching speeds up to 4500 rpm. The impressive Weiss (a Siemens company) brand motors used in the V631 combined with the other high-quality machine components lead to extremely smooth drilling and milling while improving accuracy and quality in your products.

Fast and accurate measuring

FAST & ACCURATE PROFILE MEASURING

The V631 can be equipped with the Voortman roller feed system or with a gripper truck based on your needs. Voortman’s roller feed system is known for being fast and accurate on a minimal footprint, while the gripper truck can rotate its clamp to process all kinds of profiles automatically at the fastest speeds available.

YOU CAN SAVE TIME & COSTS

Learn more, get access to the full demo video

The Voortman V631 is a real all-in-one beam drilling & milling machine enabling multiple processes on one station, saving you logistics and manual handling. With its robust frame, bearings and short tool lengths, the V631 provides high quality processing and adds impeccable value to your workshop.

We recorded a demo video in which Tom tells you everything you need to know about the Voortman V631 beam drilling & milling machine.

Interested?

DEMO VIDEO / Heavy beam processing

Heavy beam drilling, marking, milling and sawing in one go!

Voortman machines do not care whether there is a light or very heavy profile in the clamps. They can handle them with the same accuracy and efficiency, so your production can switch between the two at the drop of a hat. Take a look at this example of a heavy (W36) beam that weighs 1377 kg/m (925 lbs./ft), 77 mm (3 inch) web and 115 mm (4 1/2 inch) flange thickness. Drilling, marking, milling and sawing in one go!

THIS IS WHAT WE CALL VERSATILITY

Integration in the workshop

Combined sawing and drilling with measuring rolls

The fastest measuring and transportation system for profiles in the market

The Voortman roller feed measuring system uses two feeder rolls to move material. Two measurement wheels are installed to accurately track the profile's position. Feeder rolls are often used because of the required space and the flexibility when integrated into a larger system. With a measuring roll system, it is also possible to load a new profile once the first profile has passed the edge of the cross transports.

Since a feeder roll does not have a rail, it is possible to feed into the machine from two sides. With Voortman, you have a choice in measurement systems, making it possible to tailor the system to the characteristics of your production database.

Combined sawing and drilling with feeder truck

A strong and robust servo driven gripper truck for processing many small products

Voortman also offers a strong and robust servo driven gripper truck. This truck is the fastest truck available, adapting its velocity dynamically to the profile's total weight. This makes the truck more agile and safe for the operator. The feeder truck holds the material with a wide clamp, which is rotated automatically when the geometry of the profile demands. This measuring system is capable of moving even the heaviest profiles without losing its stability.

The gripper truck can be combined with the VB beam sawing machine - often with an automatic Short Product Removal System (SPRS) where the gripper clamps all products up to 1.400 mm (4-1/2'). during cutting, and then short products are transported sideways. With the SPRS and the gripper truck, the drill and saw become fully autonomous with clean cuts automatically dropped into a separate bin. Just start your latest production run before you close the factory for the night and arrive in the morning with all products processed and sorted on the outfeed cross transports.

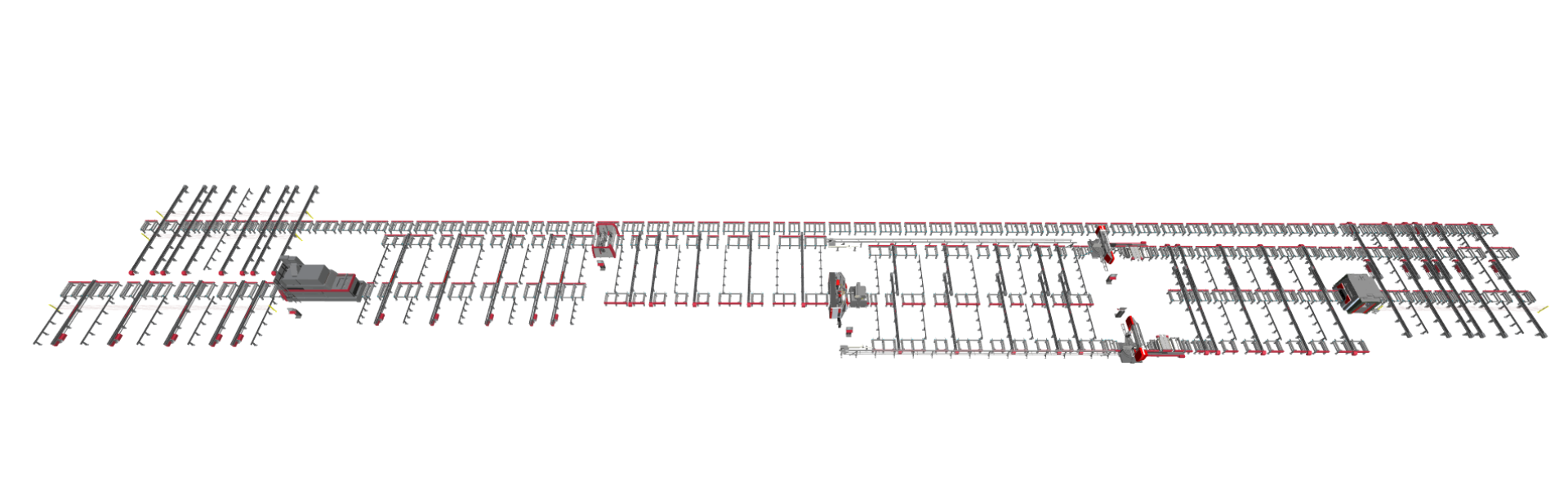

Full automation in a modular split system

Reduce labor costs and increase efficiency

MSI, also referred to as Multi System Integration, opens the door to fully automate your production by connecting machines with cross transports, roller conveyors, product buffers, and material sensors. Production data only needs to be imported once and then MSI automatically distributes the data to all machines integrated in your production system.

Vacam decides optimal material route

Based on the production on hand, customer preferences and the available machinery in the MSI-line, VACAM automatically decides the optimal route to reach the highest efficiency. MSI designates the end of transporting raw profiles and semi-finished products from machine to machine. MSI stands for one integrated production system. You can track and monitor every profile, product and future planning in real time by using VACAM, Voortman’s proprietary CNC control software installed on every machine.

Designing your optimal layout

Together with you, the Voortman team designs the entire layout based on your current or expected production characteristics, such as type of profiles, product length, number of processes, hours in your work week and budget.

Safety

An integral plan to keep your production line safe and up and running

After installing a machine or production line, Voortman installs a net of safety measures. These safety measures comprise of light curtains, emergency cords and emergency stop buttons. Voortman has made it one of its priorities to deliver a safe production line, yet not hold up production if the operator needs to enter the safe zone. This is accomplished by using gated light curtains allowing loading and unloading while the machines continue processing, and by delivering remote controls with a kill switch that operators can use when carrying out tasks inside the safety zone.

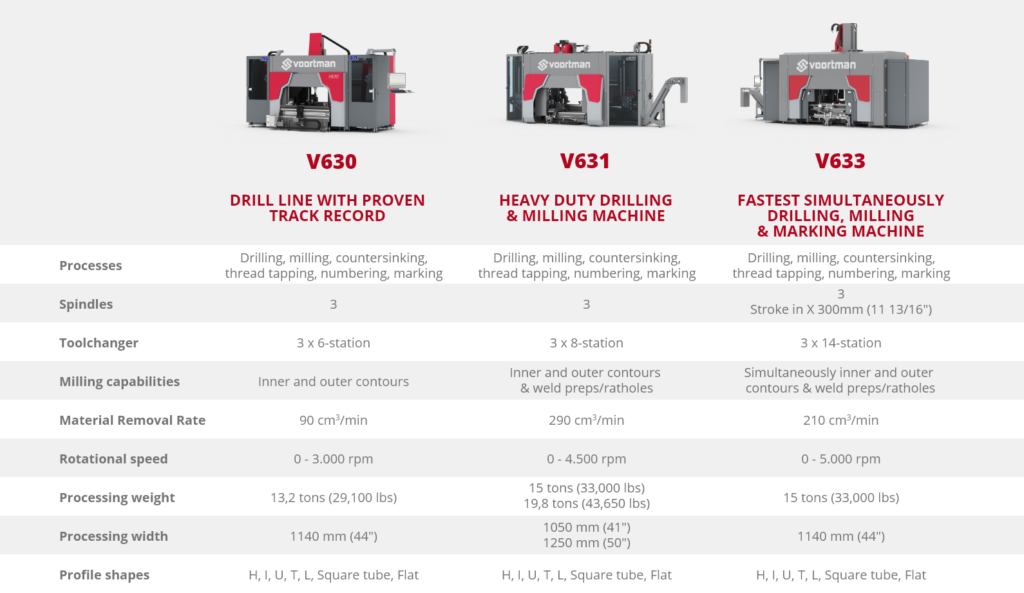

DIFFERENT SPECS FOR DIFFERENT NEEDS

Find which suits you best!

At Voortman, we offer a versatile range of machines in our beam drilling portfolio, each with unique specifications to cater to different production needs.

Take the time to explore your options and find a machine that perfectly suits your goals.

Contact us to learn more and let our team of experts assist you every step of the way.

Specifications

| Voortman V631 | |||

|---|---|---|---|

| Voortman V631/1050 | Voortman V631/1250 | ||

| Operating range | inch | 25/64 x 2 1/3 – 18 x 41 | 25/64 x 2 1/3 – 24 x 50 |

| Material weight | lbs | 33,000 | 43,650 |

| Drilling and positioning | Servo motors | ||

| Positioning speed X | f/min | 180 | 180 |

| Positioning speed Y | f/min | 100 | 100 |

| Positioning speed Z | f/min | 100 | 100 |

| Drilling units | 3 | 3 | |

| Speed | rpm (stepless) | 0 - 4.500 | 0 - 4.500 |

| Tool changer | 3 x 8 | 3 x 8 | |

| Drill holder | SK40 | SK40 | |

| Drill diameter | inch | 13/64 - 2 | 13/64 - 2 |

| Thread tapping | M6 - M30 | M6 - M30 | |

| Machine weight | lbs | 26,450 | 30,800 |