VOORTMAN V353

CORTE POR LASER DE FIBRA EFICIENTE Y FLEXIBLE DE CHAPAS DE GRAN FORMATO

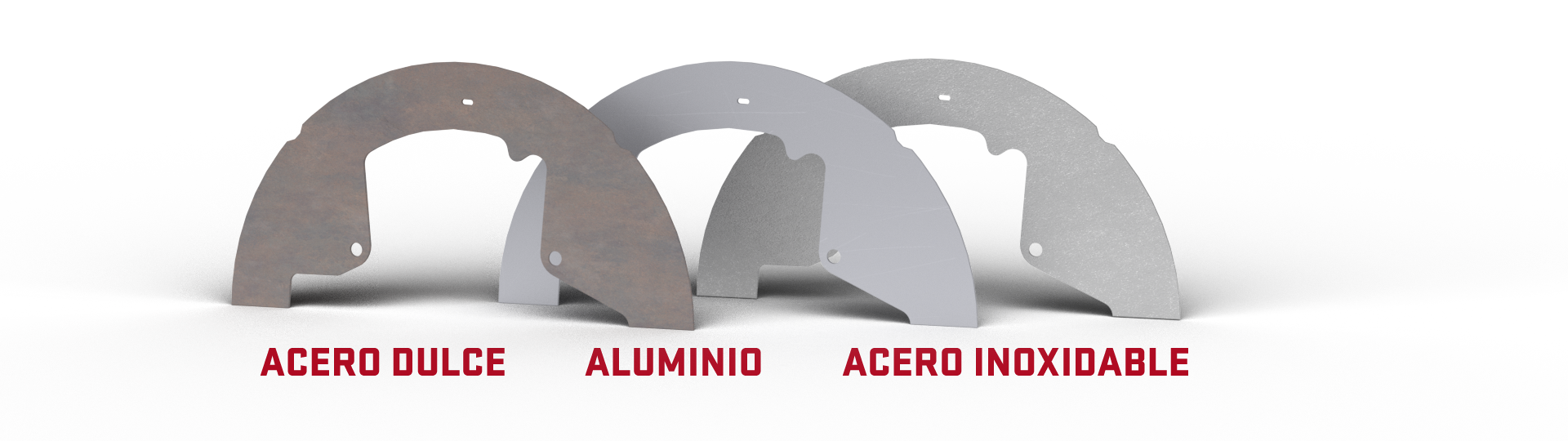

La V353 es una Maquina de corte Laser de fibra de última generación diseñada para el Procesamiento de acero carbono, acero inoxidable y aluminio con una precisión y eficiencia sin igual. Capaz de cortar Chapas de hasta 40mm (1,5 pulgadas) de espesor y manejar longitudes de mesa de hasta 36 metros (120 pies), se adapta tanto a trabajos pequeños como a gran escala. Esta flexibilidad, combinada con la capacidad de ejecutar múltiples espesores y trabajos simultáneamente, hace que la V353 sea ideal para la producción nocturna sin personal.

Utilizando la tecnología Laser de fibra, la V353 garantiza una calidad de corte superior que cumple con los estándares de la industria al tiempo que minimiza la intervención manual a través de su cambiador automático de boquillas equipado con tecnología de visión de boquillas. La avanzada Unidad de corte con bisel permite realizar cortes precisos de hasta 45 grados, suministrando productos listos para usar directamente desde la máquina. Con su gran área de Procesamiento, sus características de minimización de desperdicios y su capacidad de producción durante las 24 horas del día, la V353 reduce significativamente el coste por pieza, convirtiéndola en una solución versátil y rentable para el Procesamiento de chapas metálicas.

Productos listos para usar

La cortadora láser de fibra óptica V353 de Voortman ofrece un corte de orificios y una preparación de soldaduras precisos, a la vez que cumple la norma EN1090-2. Maneja una amplia gama de materiales y espesores, eliminando a menudo la necesidad de Taladrar gracias a la avanzada tecnología de visión y a los intercambiadores de boquillas. La máquina automatiza el Marcado para facilitar su trazabilidad y funciona con un Laser de fibra IPG de alta eficiencia con el software VACAM de fácil uso. Su Robusto diseño y Control de altura inteligente garantizan resultados fiables y de alta calidad, manteniendo tu Flujo de trabajo sin problemas y tus productos listos para el siguiente paso.

FLEXIBILIDAD MEJORADA

La V353 de Voortman maneja sin esfuerzo una amplia gama de proyectos y materiales, incluyendo acero, acero inoxidable y aluminio de hasta 40 mm (1,5 pulgadas) de espesor. El innovador cabezal de corte cuenta con planos focales y aumentos ajustables, lo que permite realizar cortes precisos en cualquier ángulo. Esta flexibilidad significa que usted puede manejar fácilmente una amplia gama de materiales y espesores con precisión, en cualquier ángulo.

Capaz de procesar grandes chapas de stock de hasta 12 metros (40 pies ) y con una cama de corte modular, la V353 ofrece una flexibilidad y fiabilidad sin igual para las tareas de fabricación simples y complejas.

Costes minimizados

El V353 es una solución potente, eficiente y rentable para las necesidades de corte por láser de alta precisión. Optimiza el uso de material y minimiza los residuos mediante el uso de grandes chapas de 3×6 metros (10×20 pies), permitiendo un eficiente Nesting (Anidado) de varias formas y manejando hasta seis grandes Chapas simultáneamente para agilizar el Flujo de trabajo. Combina tecnología Laser de fibra de alta velocidad y precisión con una base robusta para garantizar cortes fiables y de calidad, a la vez que requiere una formación mínima y mano de obra poco cualificada, lo que ayuda a mantener bajos los costes operativos. Las funciones inteligentes, como el control de altura avanzado y los adaptadores de Boquilla, evitan colisiones y protegen los componentes clave, reduciendo el tiempo de inactividad y los gastos de mantenimiento.

FUNCIONAMIENTO CONSTANTE

Esta cortadora láser es una solución de corte fácil de usar, eficiente y segura, diseñada para un funcionamiento suave y sin intervención. Tu puedes configurar múltiples trabajos, y el sistema automáticamente mide y alinea las Chapas. El cambio entre boquillas rectas y biseladas es rápido y automático, mientras que un sistema de visión supervisa el estado de las boquillas y un cepillo incorporado las mantiene limpias. El manipulador de boquillas de 24 posiciones permite realizar cortes largos e ininterrumpidos. Si se interrumpe, la función de reanudación lo retoma exactamente donde lo dejó para reducir los residuos. Los escáneres de seguridad vigilan el entorno, deteniendo la máquina si algo se acerca demasiado. Su diseño cerrado bloquea los reflejos del Laser, con sensores que aseguran que las puertas están cerradas antes de la operación.

TRANSFORME SU CADENA DE VALOR CON LA AUTOMATIZACION

Y DIGITALIZACION DE VOORTMAN

Aunque nuestras Máquinas de procesar placas ya proporcionan una notable optimización, Tu también puedes avanzar en otras áreas de tu negocio. Tu puedes optimizar todo tu proceso de Procesamiento, desde la preparacion del trabajo hasta el producto terminado, eliminando elementos innecesarios y Cuello de botella, implementando Automatizacion y Digitalizacion. Vea cómo las soluciones digitales de Voortman y SigmaNEST le permiten recopilar, conectar y analizar datos en tiempo real de forma eficaz, para que pueda tomar decisiones potentes que hagan avanzar su negocio con confianza.

Explore lo que tenemos que ofrecerle consultando nuestro nuevo folleto hoy mismo o vea el vídeo que aparece a continuación.

USABILIDAD SIMPLIFICADA

Gracias a su software VACAM fácil de usar, una vez que un Operador lo aprende en una máquina, puede manejar fácilmente cualquier máquina Voortman. La vista general de programación incorporada muestra exactamente qué trabajo debe ejecutarse a continuación, eliminando las órdenes en papel y proporcionando una visión clara de las tareas y los tiempos de producción. También comprueba la disponibilidad de herramientas antes de tiempo, evitando costosos tiempos de inactividad, especialmente durante los turnos de noche. La herramienta LoadManager simplifica la planificación de los Nidos y el seguimiento del progreso de los trabajos, permitiendo asignar y equilibrar las cargas de trabajo entre varias máquinas con un solo clic. Durante la clasificación, el Modulo de descarga de color codifica las piezas por colores según el cliente, la orden de trabajo o la ruta para mantener todo organizado. Los Operadores pueden marcar la calidad de las piezas para rechazar las de calidad inferior y reprogramarlas para futuros Nidos. La base de corte de la Voortman V353 está diseñada para facilitar el acceso, con un mínimo de componentes que retirar, por lo que la limpieza de los Contenedores de escoria requiere un tiempo de inactividad mínimo.

Especificaciones Voortman V353

| El Voortman V353 | ||

|---|---|---|

| Anchura de trabajo recta | pies | 10 |

| Longitud de trabajo recta | pies | 40 - 120 |

| Potencia de la fuente Laser | kw | 15 - 40 |

| Bisel de Anchura de trabajo | pies | 10 |

| Longitud de trabajo Bisel | pies | 40 - 120 |

| Cambiador de Boquilla | posiciones | 24 |

| Velocidad máxima de posicionamiento x-y (interpolada) | m/min | 140 |

| Velocidad máxima de posicionamiento z | m/min | 50 |

| Aceleración máxima | G | 1.0 |

| Peso máximo de la Chapa | LB/FT2 | 125 |

| Espesor máximo de corte | pulgada | 2 |