Introducing new machines & solutions at EuroBLECH

Come talk to machines and people of Voortman Steel Machinery at EuroBLECH in Hannover.

Visit the interactive booth 12-F66 from October 25 - 28, 2022

SEE OUR FULL EXHIBITION PROGRAM

- Do you want to learn more about unmanned running?

- Do you want to see in real time how to automate your production?

- Are you looking for the best in steel processing?

- Are you looking for the latest solutions to optimize your logistics?

- Are you looking for more flexibility?

- Is your operator already alerted when the machine needs attention?

Live machine demo's

Participate in various demos of the Voortman V310 plate processing machine and the Voortman V633 beam drilling and milling machine with four sub-axes. Real-time feedback, ease of use, increased interactivity, no process knowledge or programming required. The machine lets you know when you need to be at the machine. Discuss our vision on multi-processing.

Meet our latest machines and be inspired. The Voortman Plate Sorter and the Voortman Pipe Cutting Unit will be presented to you for the first time at EuroBLECH.

A fresh cappuccino and tasty Dutch specialty will be waiting for you at the booth. Come talk to machines and people.

Scroll down to see our detailed solutions and exhibition program!

SEE HOW YOU CAN INCREASE YOUR FLEXIBILITY

Increase your business moving forward with an innovative approach to multi-processing. This means that you can perform a wide variety of processes on a wide range of profiles and plates. By taking advantage of that, you will increase your opportunities and independence!

Fastest drilling, milling and layout marking machine

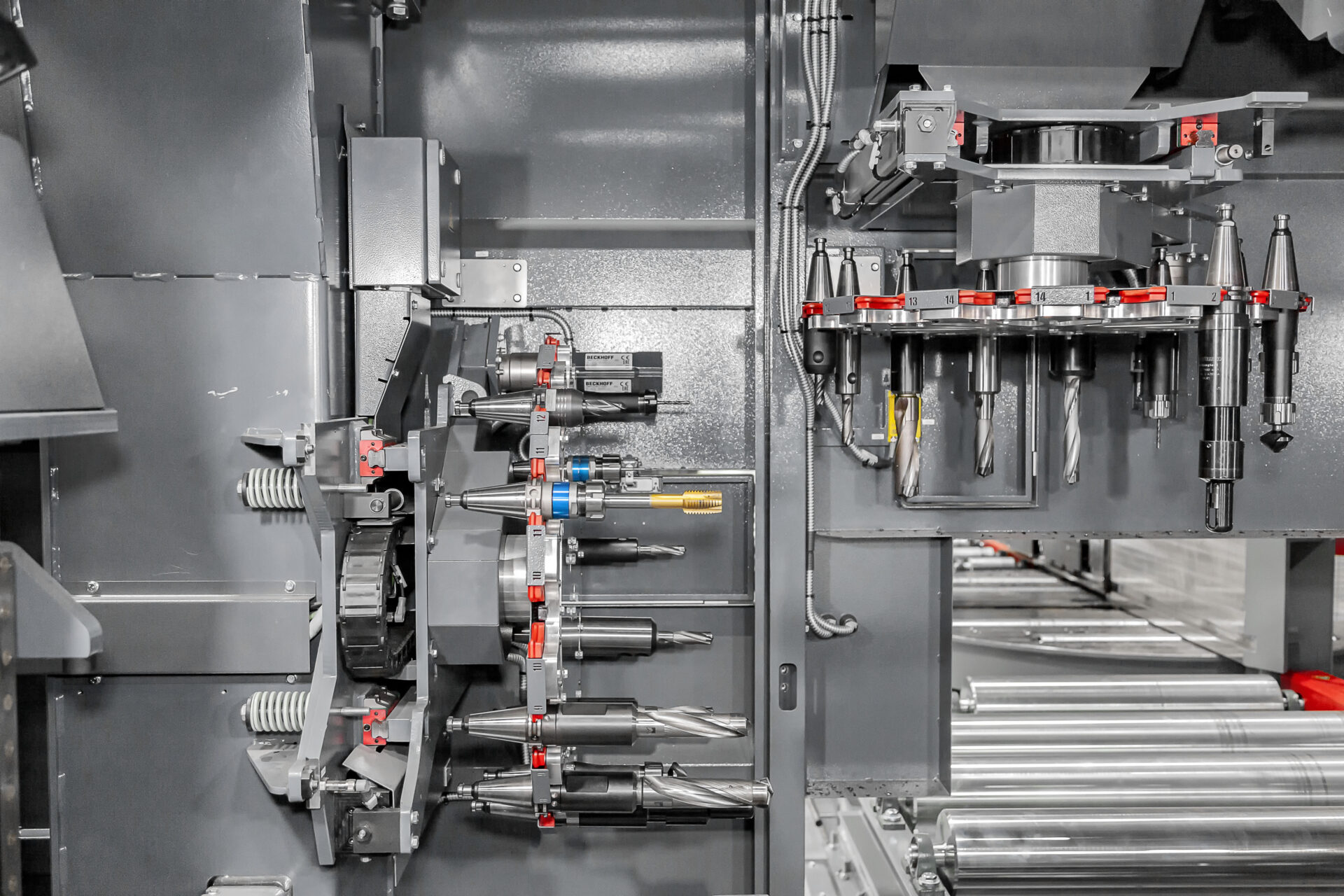

During the exhibition we will introduce you to the fastest drilling, milling and layout marking machine in the world! Four sub-axes enable simultaneously drill and mill on three sides, plus marking on four sides. The innovative solid build makes the machine truly stands out in the industry.

The design emphasis is based on strength and product quality, impressing all who have seen it in action.

The exterior of this great machine will be completely transparent, so that the efficiency on the inside can also be seen. Camera feeds will show real-time operations on a screen. Be impressed!

Pipe processing with the best cutting quality currently available

As the number of processes increases, we are also broadening our application of profiles. Let us introduce you to our NEW pipe processing unit. It is easy to integrate with your existing or new plate processing machine.

This unit is the only one in the industry that allows you to cut pipes with the same quality you are used to from our plate cutting machines. Our True Volt technology is combined with a predictive model, based on the complete cut. This makes it the best cutting quality currently available and reduces your costs and consumables at the same time!

SEE HOW YOU CAN IMPROVE YOUR LOGISTICS

Meet World's First-Ever Automated Plate Sorting Solution - the Voortman Plate Sorter

The NEW Voortman Plate Sorter will change your entire logistical routing of plate parts to your welding area, with maximum efficiency as a result. The days of sorting plate parts at the machine, missing parts at the welding area, and a complete chaos at your plate and welding area are over.

From now on you can nest and utilize your plates to the fullest.

Multiple phases and projects can be nested together in one plate, increasing your efficiency and reducing your material costs. Is the whole plate processed? Simply unload the finished parts from the cutting table, put them unsorted in a bin and move it to the Voortman Plate Sorter. It will do the rest! It scans and identifies the plates, checks their quality, sorts them into the right bin and stores them in a storage tower. It's that easy!

Create ready parts with our multi-processing solutions

Optimizing and streamlining your logistics process also is a core part of our multi-processing philosophy. Lean on Voortman's multi-processing machines in order to create a cost-efficient, flexible and streamlined production process. There's no need for moving or dividing material across different work stations anymore, resulting in less transport and intermediate stock in your workshop.

For instance, the Voortman V633 enables you to simultaneously drill holes and mark, but also mill up to a diameter of 20 mm in one powerful pass, all on one single machine! Additionally, the new pipe cutting unit extends your processing capabilities and reduces logistical movements through your factory, since the unit is placed directly next to the Voortman V303 or V310 plate processing machine.

SEE HOW YOU CAN AUTOMATE YOUR PRODUCTION

A level of automation and feedback you've never seen before!

Our next-level VACAM Software automates your plate production and provides lots of real-time feedback. Our machines have the largest touch panels in the market, and an easy-to-use interface makes it easy to navigate through them. But what really sets our machines apart is what's under the hood: One-button automation. It means that even the toughest processes can be carried out by anyone— Even if they have never done it before.

For example, do you want to create contours with mill quality on the Voortman V310? With the brand NEW Hybrid Milling functionality, you can save time and costs by opting to cut a part of the contour first, then mill away the remaining part. No process knowledge or programming needed; the machine makes these smart choices and does the work for you.

Speaking about smart choices, the software provides consumable proposals and shows tool overlap per nesting in order to maximize up-time and consumable lifetime.

Voortman's far-reaching emphasis on unmanned production

We make unmanned production as accessible as possible with our steel solutions. There's no need to be constantly present at the machine. When it comes to processing plates on the Voortman V310, simply cluster jobs, buffer multiple plates and activate the Unmanned Mode to bypass manual interventions for longer periods. The machine lets you know when to be present at the machine by the Operator Dashboard. During times when no one's needed at the machine, value can be added in other areas in the workshop.

Same counts for our latest addition to our beam drilling and milling portfolio, the Voortman V633. With its four independent sub-axes and all automated functions and built-in conveniences, the V633 is a real industry standout. Again allowing you to focus on other jobs in the workshop while processing unmanned.

It maximizes your productivity by using a full range of 14 tools per spindle and even allowing you to add or switch between those tools without causing downtime.

Experience it live with real-time processing demos at our booth!

LEARN HOW YOU CAN INCREASE UPTIME

Perfectly balanced with Evi

The success of any production is dependent on the balance between human interaction and machine automation. To contribute to success and maximize your machines' productivity, we would like to introduce you to Evi!

Evi will help you boost your uptime and output, providing insight on the current status of your machines, as well as tonnage and products produced during a specific timeframe. A clear and easy-to-use dashboard allows you to analyze data and explore instances of downtime. The cloud-based software tool also gives real-time information to machine operators, who are notified when their machine requires attention.

Evi is designed to be accessible from any location and any device—you'll always have access to the latest information. Evi is present at our booth and she likes to show off all the features we offer! Come and meet her.