V310

THE ULTIMATE AND MOST COMPLETE PLATE PROCESSING MACHINE

A plate processing solution that combines advanced automation with versatile, intelligently engineered cutting and milling capabilities. The V310 is ideal for fabricators or manufacturers who need to perform a full range of processes on steel plates.

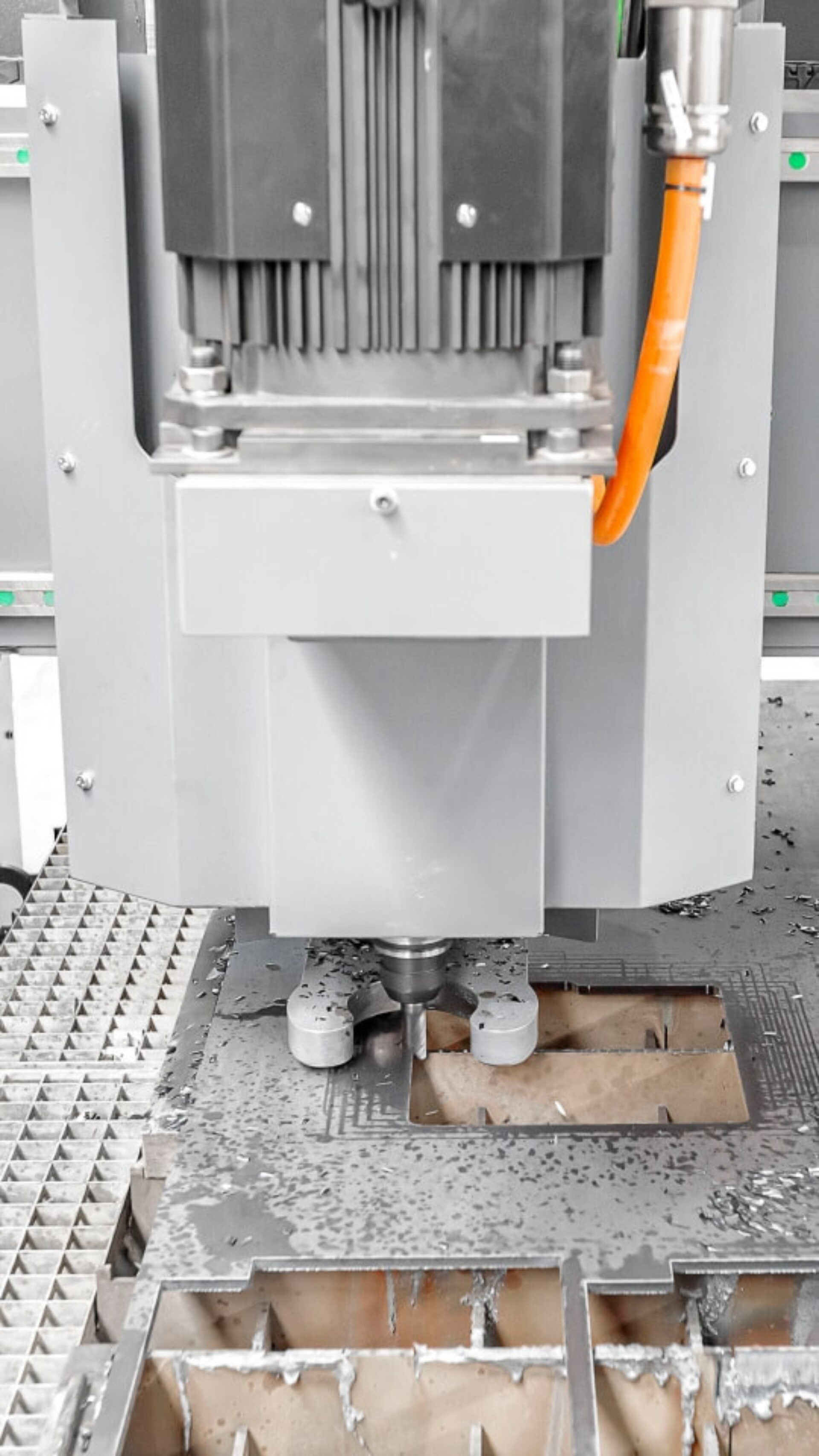

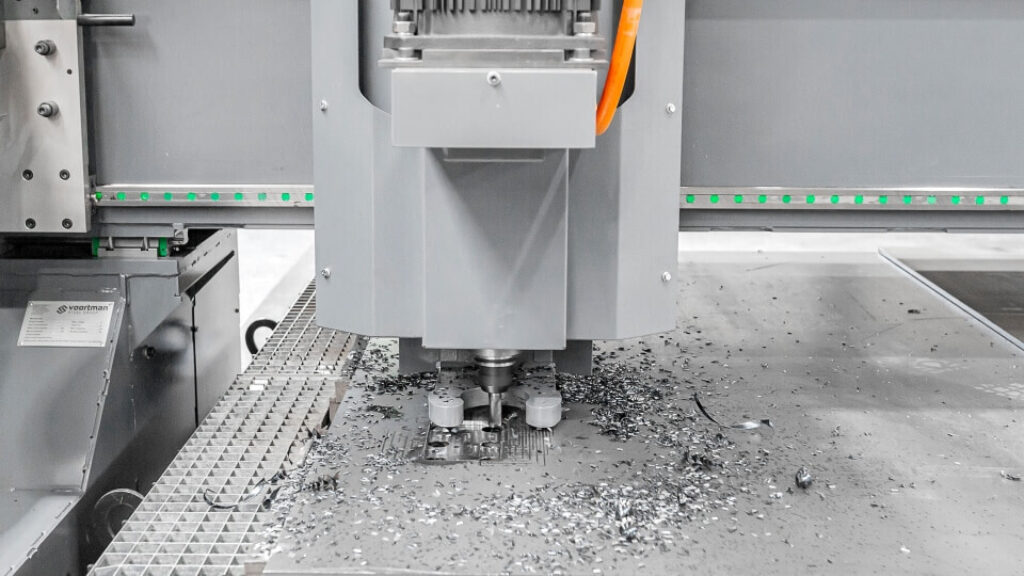

- Fully automatic high-speed carbide drilling, milling, and thread tapping

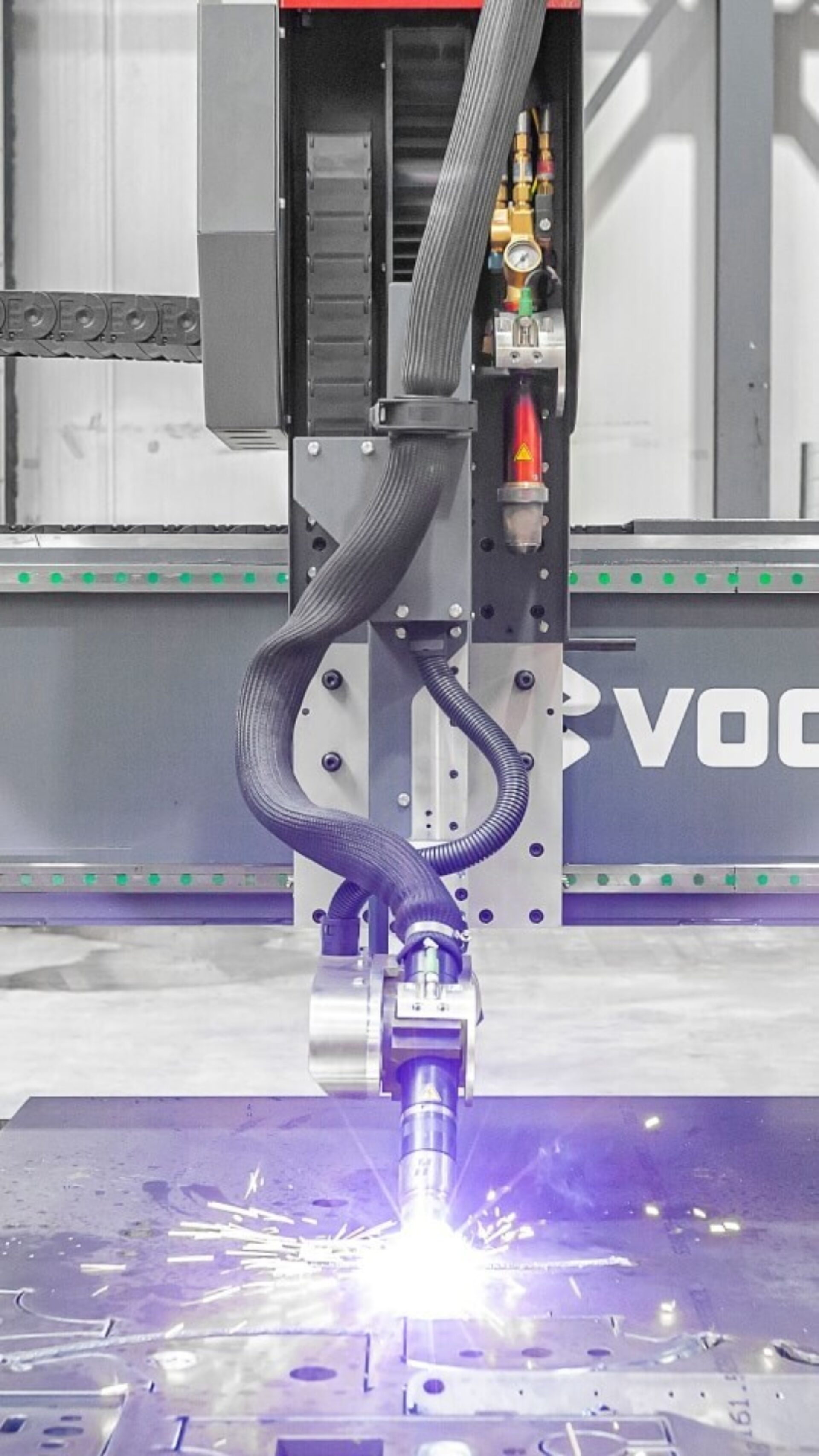

- High-definition plasma with unrivalled 3D bevel cutting quality

- Scheduling and buffering for complete unmanned operation of different plates

- Real-time dashboard insights to maximize processing uptime and monitor progress

Compatible with software solutions:

LogicSteel CADCAM | SigmaNEST

OVERVIEW

The Voortman V310 is a multifunction CNC plate machine combining plasma and oxy-fuel cutting, drilling, tapping, milling and bevelling in one setup. It processes plates up to 200 mm and handles holes from 5–50 mm with threads up to M30. With up to 28 tools, automated selection, advanced software and unique plasma cutting technologies, it’s built for high automation, precision, uptime and reduced manual labour through lean, lights-out workflows.

MACHINES IN THIS PRODUCT LINE

SUCCESS STORIES

We deeply value our customers and their feedback; it's what drives us to keep improving and innovating. Curious how our machines make a difference? Hear directly from our customers as they share their experiences.

APPLICATIONS

FEATURES

28 TOOLS FOR MAXIMUM FLEXIBILITY

An 8-position tool changer mounted on the gantry for rapid tool swaps close to the drilling head, complemented by an additional 20-position stationary tool changer that extends capacity and supports fully automated tool exchange.

NON-TCP BEVEL HEAD

The V310’s non-TCP bevel head offers high rigidity, accuracy, and low maintenance. Its compact design reduces vibration and eliminates TCP calibration, ensuring faster setup and reliable operation. Combined with Xtensive Bevel Technology, it automatically corrects angles for consistent, high-quality bevel cuts.

VERY HEAVY & RIGID DESIGN

The V310’s gantry design is specially engineered for heavy drilling operations. Its robust, rigid construction minimizes vibration and ensures stable feed rates, even with large hole diameters. This strength delivers higher accuracy, longer tool life, and consistent performance during demanding drilling and milling tasks.

BENEFITS

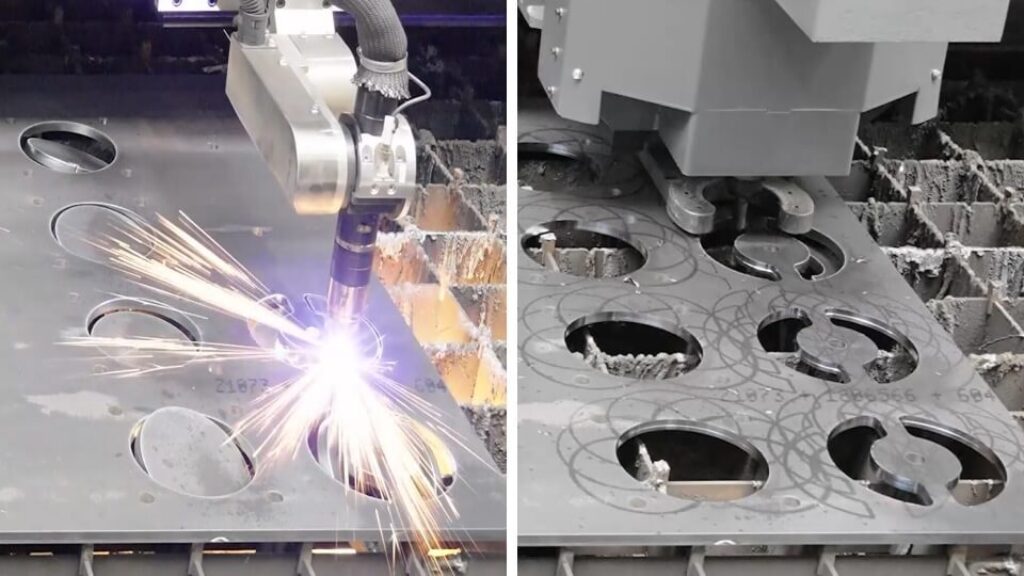

HYBRID MILLING

Hybrid Milling function saves time and costs by plasma cutting first, then milling the rest — automatically, with no programming or process knowledge required.

LOWERED X-RAIL

In a nesting of 400 parts, operators may cross the rails hundreds of times. That’s why the X-rail is designed with a stair-like step height, making loading and unloading easier.

UNMANNED OPERATION

Process multiple plates with buffer management, paperless dashboarding, job clustering, automated tool selection – maximizing uptime with minimal supervision.

SMART DRILLING & MILLING

Sequence of clamp measurement, contact drill with material detection, torque measurement – improve performance of the process and lifetime of the tooling.

SPECIFICATIONS

UPGRADE YOUR MACHINE

Extend machine length

With the modular construction of both the machine and the cutting table you are assured of maximum output. Extend your X-rail and table length to scale effortlessly as your production demands increase.

Second gantry on one x-rails

A second gantry can be added to the same X-rail system, allowing two machines to work simultaneously on one long table improving throughput and maximizing uptime without increasing floor space.

Pipe Cutting Unit

The V310 can be equipped with a pipe cutting unit, allowing precise plasma cutting of round tubes directly on the same machine with perfect profiling and belling for welding.

Load Manager Module

With the SigmaNEST Load Manager module, you have full control over complex work orders, production can be assessed quickly and orders can be easily assigned to any compatible machine.

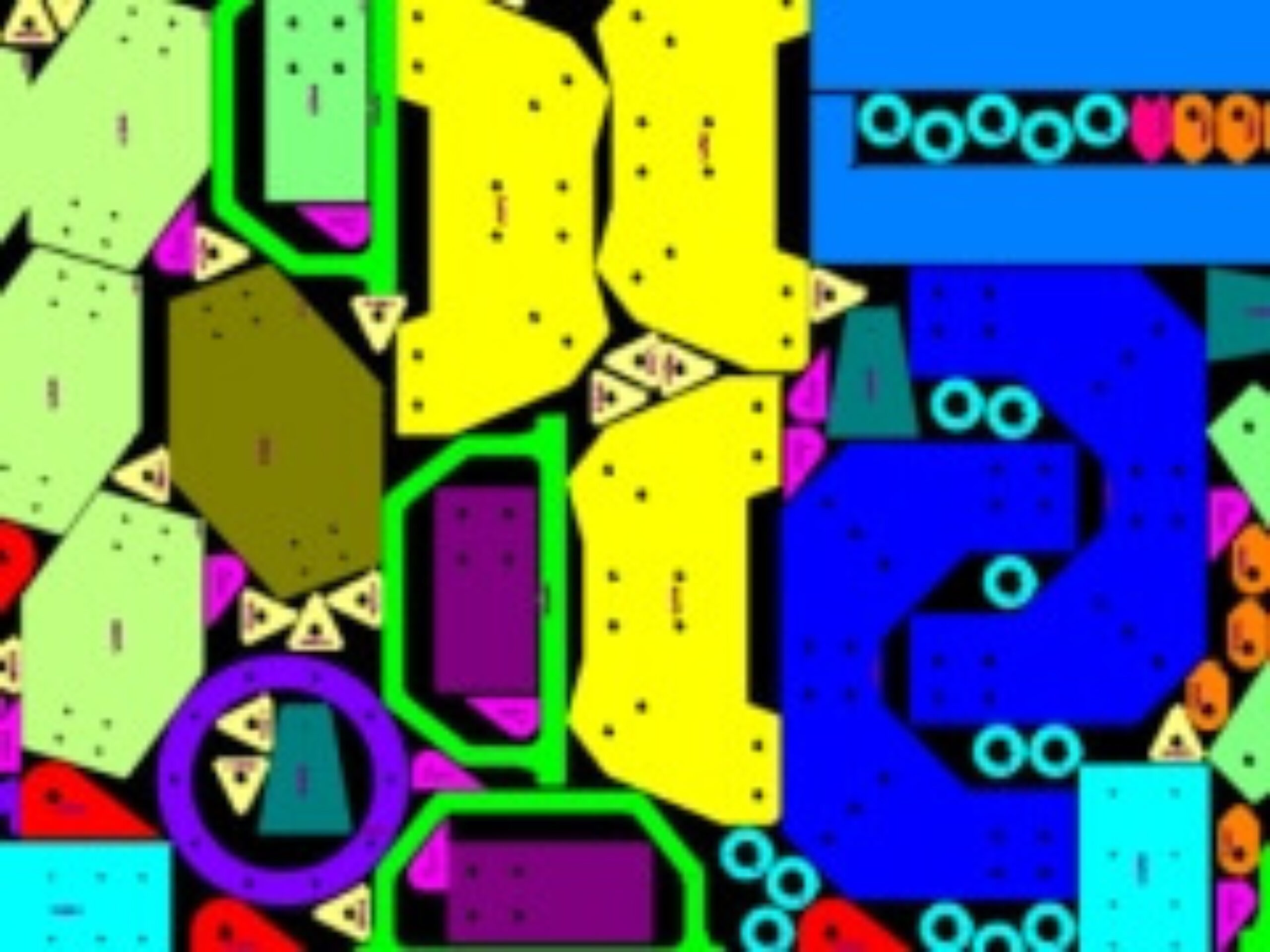

Color Offload Module

Make unloading easier and more accurate by color coding. The Color Offload module eliminates operator confusion by displaying nested parts in colors that can be assigned by customer, work order or factory routing.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

The V310 uses a heavy-duty gantry with helical rack-and-pinion drives and precision linear guides. This combination minimizes mechanical play and resists vibration even during heavy drilling or high-speed cutting, ensuring consistent accuracy over years of operation with minimal recalibration.

Voortman offers remote diagnostics, preventive maintenance packages and full service assistance. Most issues can be solved remotely through the machine interface, reducing downtime and service costs. Spare parts are stocked regionally, ensuring fast response when physical intervention is required.

The V310’s cutting table can be equipped with a shuffle conveyor that automatically transports slag and small parts into collection bins. This significantly reduces manual bin emptying and handling. By preventing buildup beneath the cutting zone, it also improves dust extraction efficiency, allowing fumes to be removed more effectively from the cutting process — ensuring a cleaner and safer working environment.

The machine’s gantry and bridge are specially engineered for heavy drilling. Their rigid construction minimizes vibration and ensures stable feed rates even for deep or large-diameter holes, resulting in higher precision, longer tool life, and consistent performance during demanding drilling and milling tasks.

The V310 features a laser pointer that can be used also to trace the outer contour of the nesting on the plate before cutting. This allows operators to visually verify that all parts fit correctly, helping to avoid material waste and confirm alignment without starting the actual cutting process.