HOW WE MAKE UNMANNED LIGHTS-OUT PRODUCTION MORE ACCESSIBLE

Home | Knowledgebase| How we make unmanned production more accessible

Increase interaction

and ease for your operator

With built-in process knowledge and automations, your operator is relieved of specifically needed knowledge. A 24" touch panel provides valuable information and suggestions to make the production process as smooth as possible. We worked hard to simplify and shorten common manual tasks. The ease of your operator guarantees continuity in production quality and maximizes overall uptime.

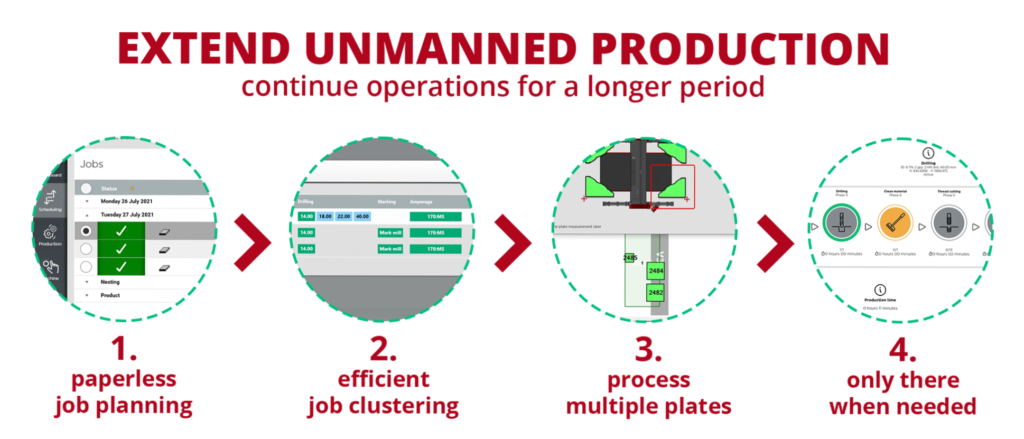

In order to provide you with as much machine feedback and information and to keep your plate processing machine running as efficiently as possible, some ground-breaking functionalities have been added to our VACAM control software. Herewith, you can appoint your operators as managers, since their main task will shift from operating the machine to loading and unloading and managing the entire workshop. How? Read more below!

Go unmanned with next-level features

Optimal efficiency - even overnight

Increase interaction and ease for your operator

It doesn't have to be challenging

JOIN US FOR A LIVE ONLINE DEMO

See what Voortman machines are capable of or see your own product created on our machinery!

Do you want to see a demo of one of our machines or see your product being created? From this moment on it is possible to get a live online demo of a machine of your choice and see your own product being produced. Just send us your product file and our experts will tell you everything you need to know and answer all your questions, while you can choose from which angle you want to watch the demo.