FASTEST DRILLING, MARKING AND MILLING

The Voortman V633 is the latest in our line of drilling and milling machines.

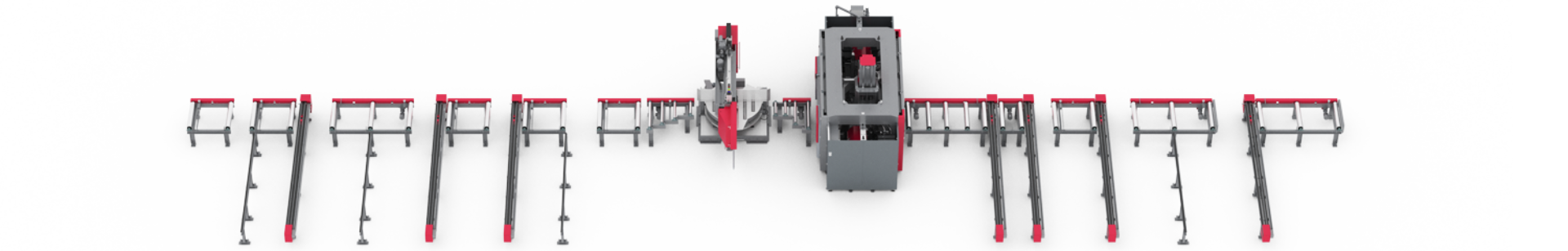

Four independent sub-axes make the fastest drilling, marking and milling machine ever made. We’re known for our ability to consistently achieve high quality and speed. By implementing multiple sub-axes, we can now simultaneously perform these features on three or even four sides at the same time.

We go the extra mile. Equipped with four sub-axes it can process three or four sides simultaneously. Drill holes, mill and mark with unprecedented stability, speed and quality. With its innovative and solid build, this machine truly stands out in the industry.

MAXIMIZE YOUR OUTPUT

AND EXCEED YOUR CAPACITY

Meet the fastest drilling, milling and marking machine in the world.

This machine does everything all at once, and it's unmatched powerful, too.

In the earliest designs, engineers planned for the machine to withstand powerful forces. Forces which are released when performing heavy processing simultaneously on all sides. We made our initial emphasis on strength and product quality, and the result has impressed everyone who has seen it in action.

VOORTMAN WEBINAR \ UNVEILING THE V633

https://youtu.be/jzf3jK4pOPk?s...

To celebrate the launch of the V633 we hosted a live webinar where the V633 was unveiled, with a live demo. We look back on a successful webinar with a large number of participants and interesting questions! Our presenters Henk Maassen van den Brink (Sales Director) and Valentijn Velten (Product manager), covered all the things you don't want to miss about this machine. Missed the webinar or want to watch it again? You can watch the recorded version here!

UNMATCHED ACCURACY AND QUALITY

YOU'LL BE AMAZED

This machine is made to deliver quality. The machine can easily handle the powerful forces coming from the three drilling units. Everything within this machine is subservient to consistent quality, such as accurate measuring systems, short tool lengths and a very rigid sturdy box frame. Even when milling three sides of your material in one pass, and at the same time, the quality is real.

Impressive

milling

AUTONOMOUS PRODUCTION WITH GREAT EASE OF OPERATION

PROVIDES A WAY TO FOCUS ON OTHER TASKS

This machine comes with a complete package of features that make a real difference to assist operators.

Less operator time is required in preparation, production and maintenance.

The automated functions and built-in conveniences of this machine allow operators to focus on other jobs in your workshop while processing unmanned.

WHAT ABOUT THOSE STITCHES?

To ensure a safe and optimal process and a possible follow-up automatic production in an MSI production line, large debris parts stay attached to the profile by their outer contours.

Loose parts with great speed can damage your machine, or even worse, injure your employees.

All it takes is a grinder to remove the remaining stiches for a product that is instant-ready for welding or construction!

Integration in your workshop

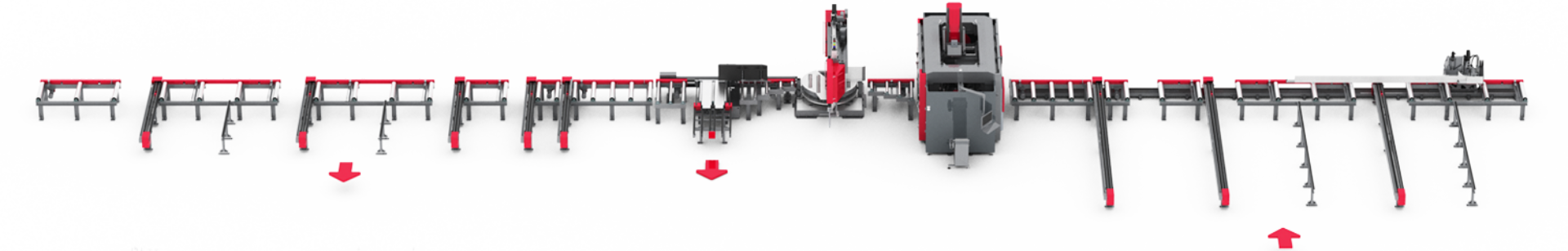

Combined sawing and drilling with measuring rolls

The fastest measuring and transportation system for profiles in the market

The Voortman roller feed measuring system uses two feeder rolls to move material. Two measurement wheels are installed to accurately track the profile's position. Feeder rolls are often used because of the required space and the flexibility when integrated into a larger system. With a measuring roll system, it is also possible to load a new profile once the first profile has passed the edge of the cross transports.

Since a feeder roll does not have a rail, it is possible to feed into the machine from two sides. With Voortman, you have a choice in measurement systems, making it possible to tailor the system to the characteristics of your production database.

Combined sawing and drilling with feeder truck

A strong and robust servo driven gripper truck for processing many small products

Voortman also offers a strong and robust servo driven gripper truck. This truck is the fastest truck available, adapting its velocity dynamically to the profile's total weight. This makes the truck more agile and safe for the operator. The feeder truck holds the material with a wide clamp, which is rotated automatically when the geometry of the profile demands. This measuring system is capable of moving even the heaviest profiles without losing its stability.

The gripper truck can be combined with the VB beam sawing machine - often with an automatic Short Product Removal System (SPRS) where the gripper clamps all products up to 1.400 mm (4-1/2'). during cutting, and then short products are transported sideways. With the SPRS and the gripper truck, the drill and saw become fully autonomous with clean cuts automatically dropped into a separate bin. Just start your latest production run before you close the factory for the night and arrive in the morning with all products processed and sorted on the outfeed cross transports.

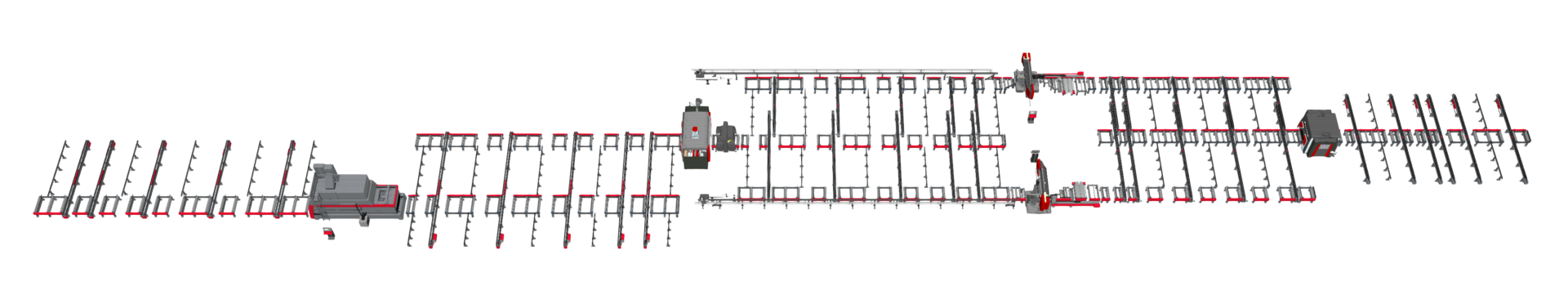

Full automation in a modular split system

Reduce labor costs and increase efficiency

MSI, also referred to as Multi System Integration, opens the door to fully automate your production by connecting machines with cross transports, roller conveyors, product buffers, and material sensors. Production data only needs to be imported once and then MSI automatically distributes the data to all machines integrated in your production system.

VACAM decides optimal material route

Based on the production on hand, customer preferences and the available machinery in the MSI-line, VACAM automatically decides the optimal route to reach the highest efficiency. MSI designates the end of transporting raw profiles and semi-finished products from machine to machine. MSI stands for one integrated production system. You can track and monitor every profile, product and future planning in real time by using VACAM, Voortman’s proprietary CNC control software installed on every machine.

Designing your optimal layout

Together with you, the Voortman team designs the entire layout based on your current or expected production characteristics, such as type of profiles, product length, number of processes, hours in your work week and budget.

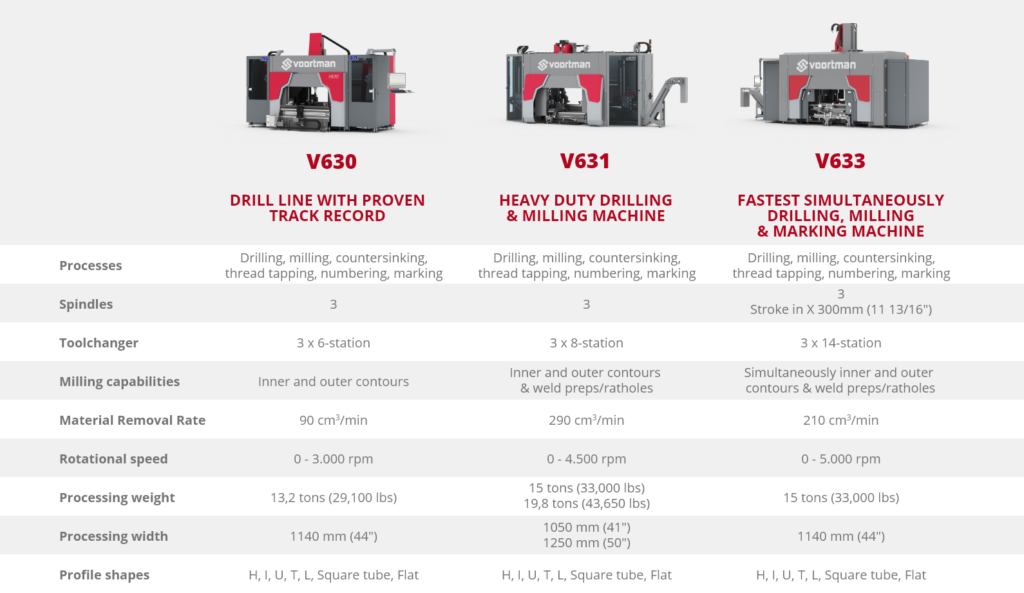

DIFFERENT SPECS FOR DIFFERENT NEEDS

Find which suits you best!

At Voortman, we offer a versatile range of machines in our beam drilling portfolio, each with unique specifications to cater to different production needs.

Take the time to explore your options and find a machine that perfectly suits your goals.

Contact us to learn more and let our team of experts assist you every step of the way.

Specifications

| Voortman V633 | ||

|---|---|---|

| Voortman V633 | ||

| Operating range | inch | 25/64 x 2 – 18 x 44 |

| Material weight | lbs | 33.100 |

| Machining and positioning | Servo motors | |

| Positioning speed X | f/min | 82 |

| Positioning speed Y | f/min | 82 |

| Positioning speed Z | f/min | 82 |

| Drilling units | 3 | |

| Spindles stroke in X | inch | 11 13/16 |

| Tool changer | 3 x 14 | |

| Drill holder | SK40 | |

| Drill diameter | inch | 13/64 - 1-37/64 |

| Thread tapping | M6 - M30 | |

| Machine weight | lbs | 26,460 |