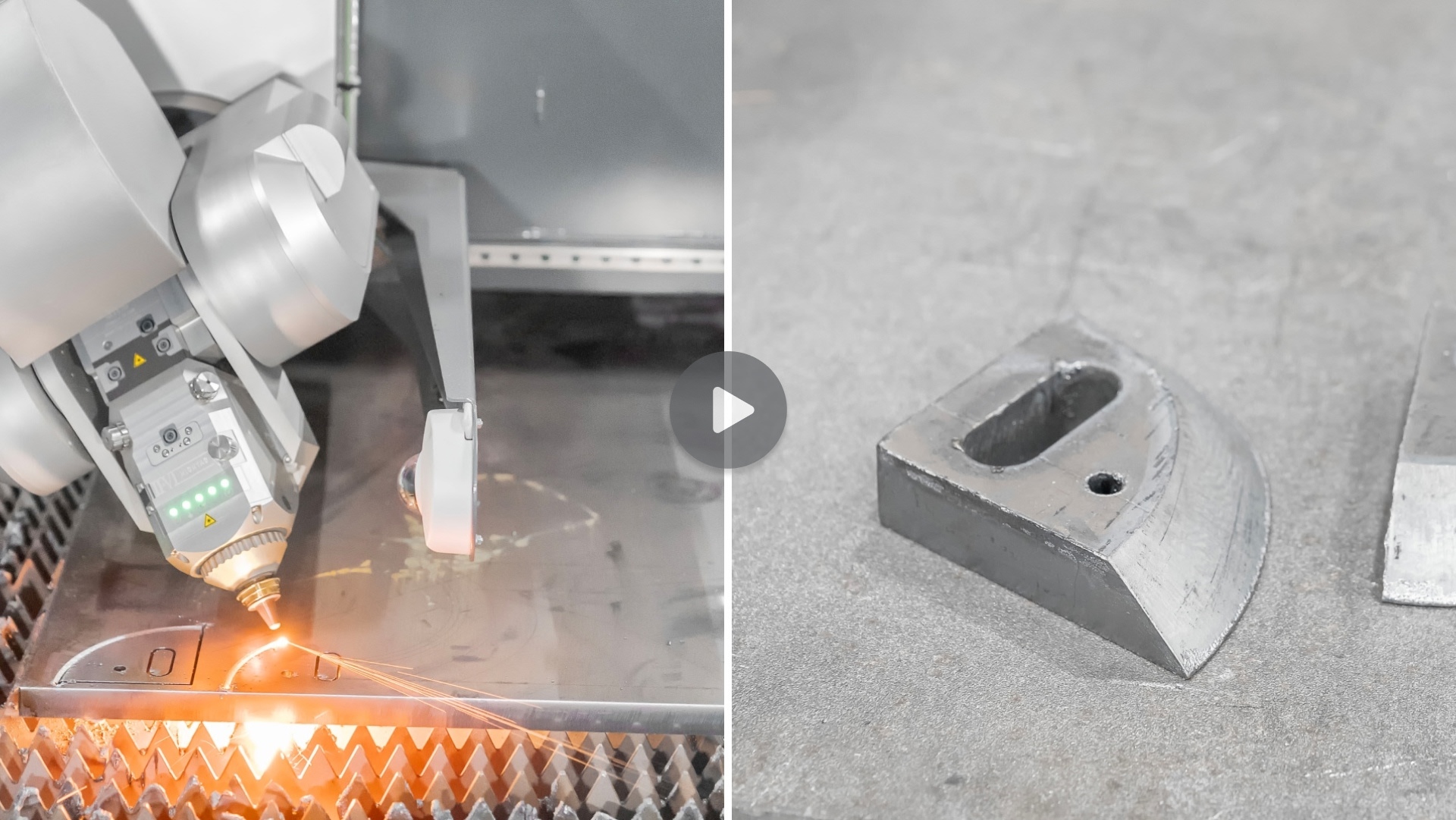

DEMO - V353: Bevel laser cutting

The two components shown here demonstrate the V353’s advanced bevel cutting capabilities in a real‑world application. Both parts were produced from 25 mm thick steel using a 15 kW fiber laser, featuring precise reminder cuts and complex 3D bevel geometries. The beveled edges are clean and consistent, with smooth transitions between straight cuts and angled surfaces, illustrating how the machine maintains accuracy and surface quality even when cutting multi‑axis contours.

This example highlights the strength of laser bevel cutting on the V353: producing weld‑ready parts directly from the cutting process. Traditional bevel preparation often requires secondary operations such as milling or grinding. With the V353, bevels are cut directly into the plate with high positional accuracy, reducing manual labor and ensuring that fit‑up at the next production stage is faster and more consistent.

The Voortman V353 is designed to handle a full range of industrial bevel types, including A‑, V‑, X‑, K‑, and Y‑bevels up to 45 degrees. Its high‑dynamic cutting head and advanced control software make it possible to combine straight cuts and bevel cuts in a single, uninterrupted process. This allows manufacturers to create complex parts from flat plate while maintaining full control over geometry and edge preparation.

What sets the V353 apart in bevel cutting applications is its stability, automation and repeatability. Intelligent cutting strategies, automatic parameter selection and unmanned production capabilities ensure consistent bevel quality across multiple parts and thicknesses. For companies working in steel construction, heavy equipment or fabrication, the V353 enables efficient production of complex, ready‑to‑assemble parts—combining flexibility, precision and high output in one automated cutting solution.

REFERENCES & RESOURCES