V353

LARGE FORMAT PLATE CUTTING

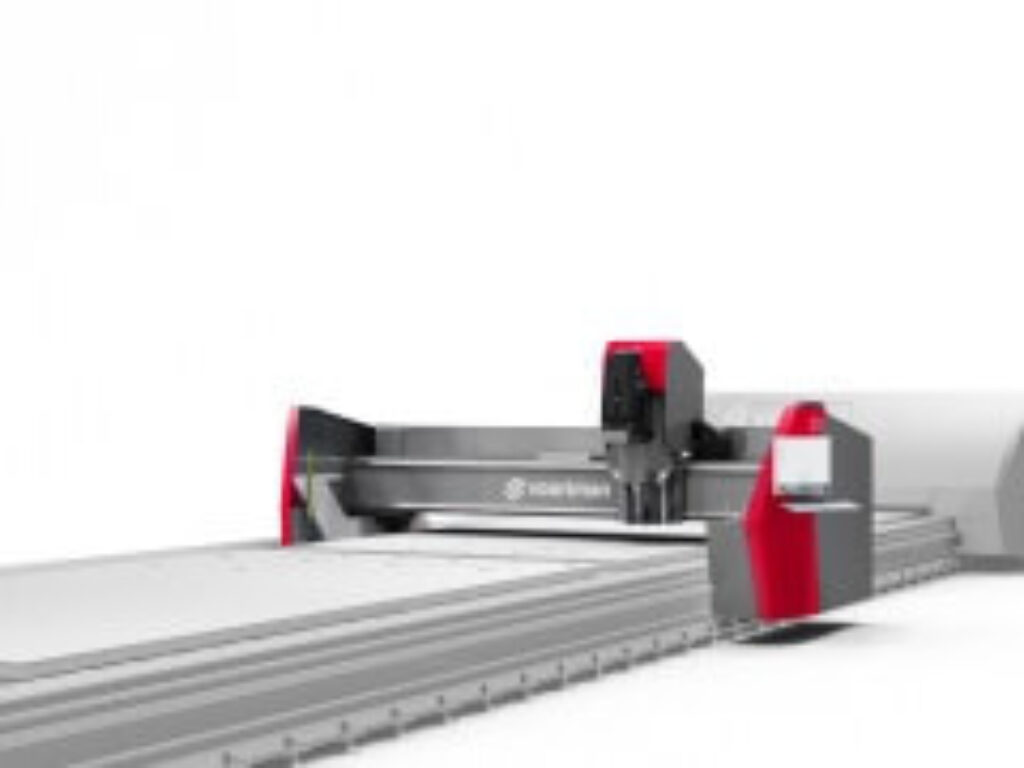

The Voortman V353 is a powerful fiber laser cutting machine for large plates. It combines high efficiency with full automation to deliver production-ready parts at unmatched output.

- Achieve 3x more output compared to traditional cutting methods.

- Cut labor costs with highly autonomous processing capabilities.

- Fewer material movements due to an extra-large cutting bed.

- Run continuously with overnight cutting across multiple thicknesses.

- Boost material yield using large-format plates for efficient nesting.

- Lower operating costs by reducing consumable usage.

12 meters up to 36 meters, modular per 3 meter.

Compatible software:

SigmaNEST, VACAM

OVERVIEW

The Voortman V353 processes plates efficiently and with minimal operator input. It creates precise cuts, including bevel cuts up to 45 degrees. Cut parts as long as the table it’s mounted on, which is modular from 12 up to 36 meters (40 - 120 feet) in length. The V353 handles thicknesses up to 75 mm (3 inches). And with up to 40 kW of laser power, automatic nozzle changes and a modular design, it runs continuously for maximum productivity. What are you waiting for? Turn plates into production-ready parts with unmatched output.

APPLICATIONS

HIGHLIGHTS

EXTRA-LARGE PROCESSING AREA

Size is no longer a limitation. Handle plates up to 36 meters (120 ft) long and 3 meters (9.84 ft) wide. Keep multiple plates on the table for rush jobs or big projects without constant changeovers.

BENEFITS

OPTIMIZED GAS MIXING

The V353’s ability to automatically mix gases for optimal balance between quality and cost is an advanced feature that improves efficiency and reduces operator workload.

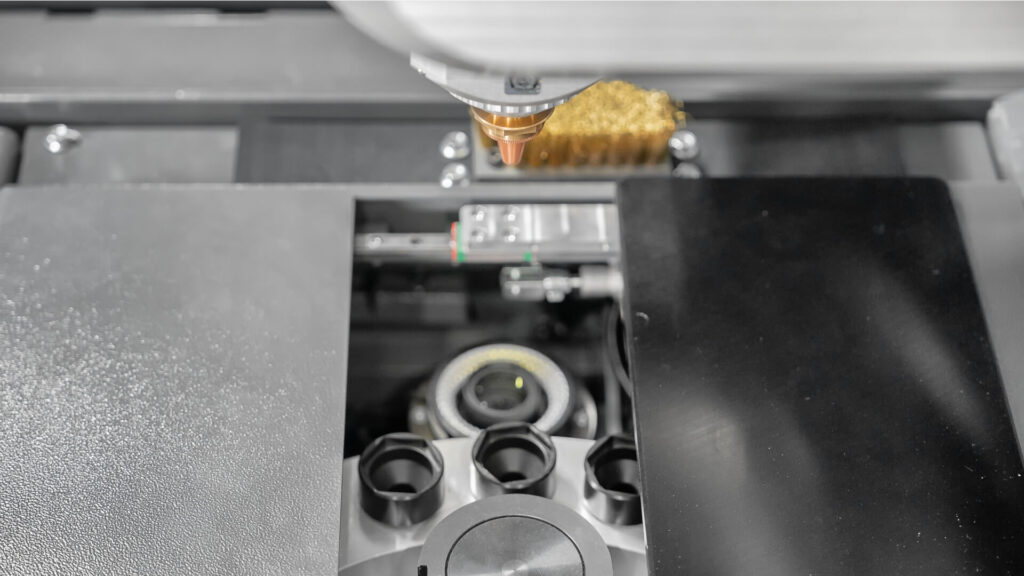

AUTOMATIC NOZZLE HANDLER

Manual nozzle changes take time. The V353 automatically selects the correct nozzle for each cutting task. With 24 positions, integrated vision, and cleaning, this handler ensures consistent quality and minimizes downtime.

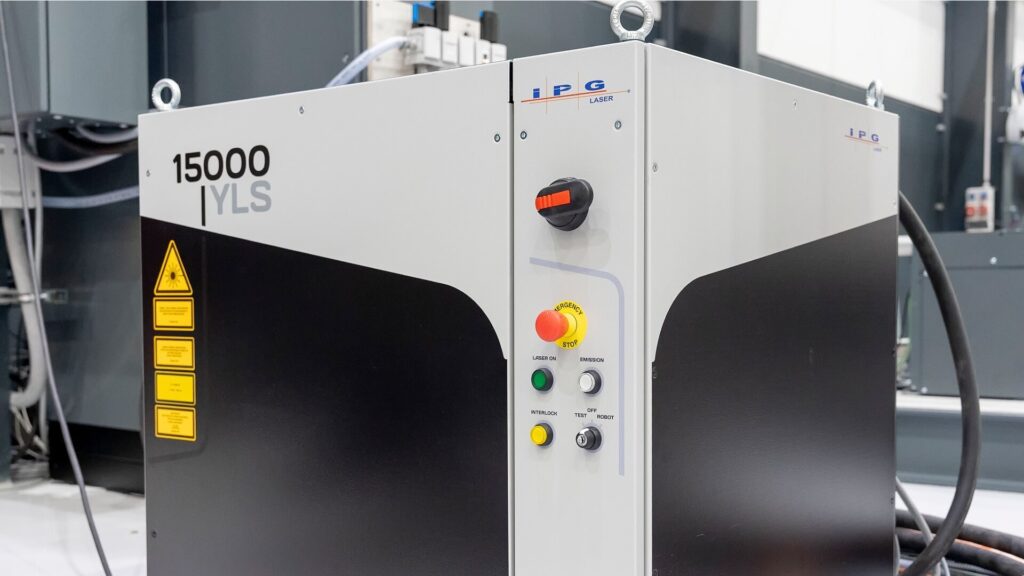

HIGH-POWER CUTTING

Choose 15 or 40 kW fiber laser power for clean cuts up to 75 mm (3 inches) thick. Perfect for heavy-duty applications requiring speed and precision.

LASER SAFETY CLASS 1

The V353’s fully enclosed housing prevents laser reflections and radiation, creating a safe environment for operators. Integrated sensors detect burnouts and ensure doors are closed before operation, guaranteeing maximum safety during cutting.

DOWNLOAD SPECIFICATIONS

UPGRADE YOUR MACHINE

Add drilling, tapping, and milling – V210 Extension

The V210 is a seamlessly integrated unit that adds drilling, tapping, and milling to your V353. Mounted on the same rails, it transforms your machine into a hybrid plate processing system. More about the V210 extension >>

Table Length

Customize your V353 to fit your production needs. The working area is always 3 meters wide, but length is modular, starting at 12 meters and extendable in 6-meter increments up to 36 meters.

Parking positions

An optional gantry parking position allows gantry to move out of the working area, enabling full‑length plate loading across the entire cutting bed.

Laser power

Choose the fiber laser power that fits your production needs, with output levels from 15 to 40 kW. The V353 is available with high‑quality laser sources from IPG or MaxPhotonics.

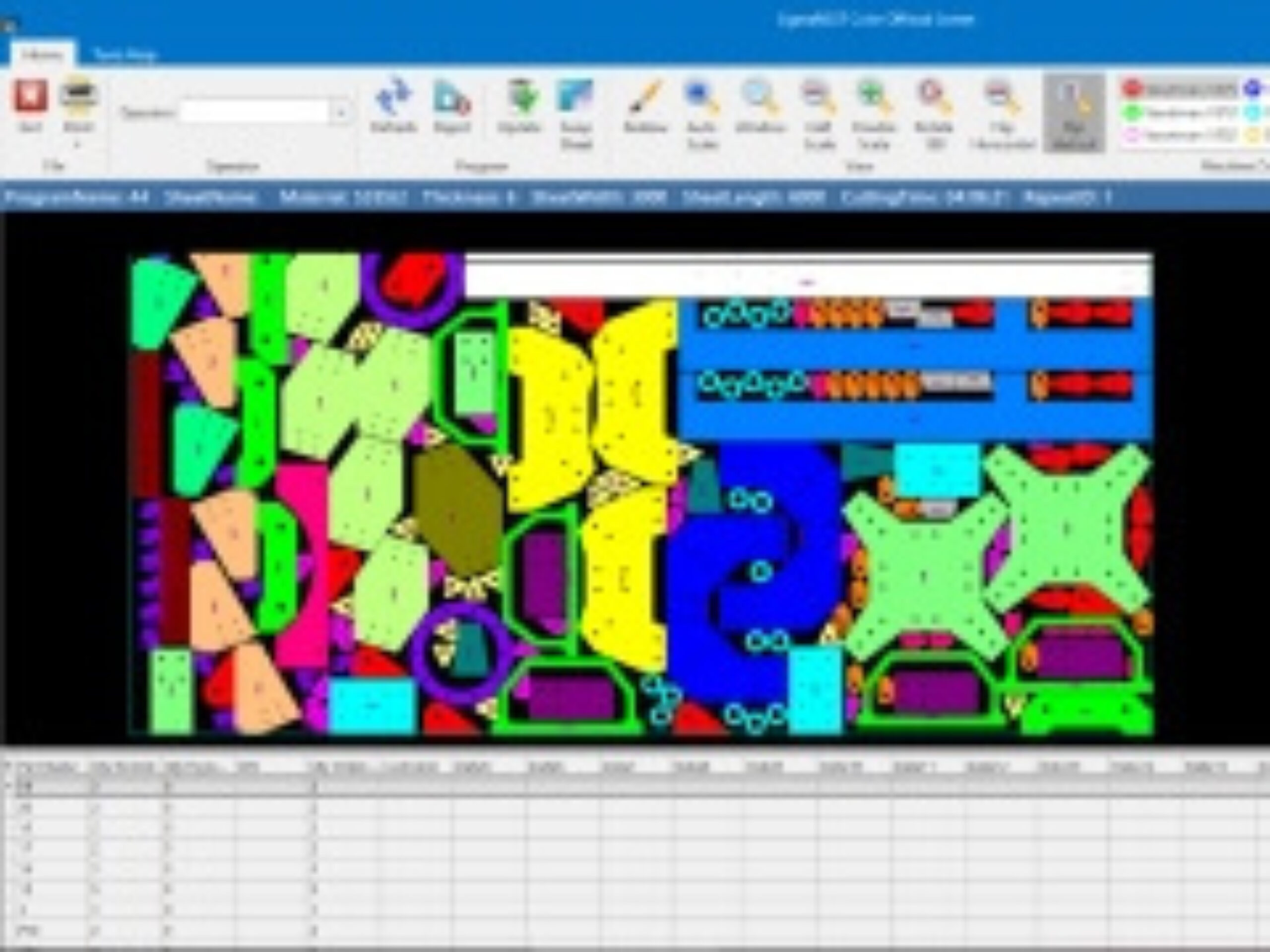

SigmaNEST options

The V353 is supplied as standard with SigmaNEST Techno, including support for drilling and bevel cutting. PowerPack is available as an option, adding plate inventory and remnant management. In addition, Color Offload and the optional Load Manager are available.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

FAQ

The V353 processes plates up to 3×36 meters (10×120 feet) and thicknesses up to 75 mm (3 inches).

Yes, the V353 delivers precise A-, V-, X, K, and Y bevel cuts up to 45 degrees.

No, the V353 is highly autonomous, reducing the need for high-skilled labor. Once parameters for the specific material are set, the machine takes care of the rest.

Yes. The V353 is designed as a fully integrated safety concept and complies with Laser Safety Class 1. Its enclosed housing, combined with continuous area monitoring, ensures safe operation even at very high speeds. Multiple safety scanners monitor the surroundings around and above the machine during loading, unloading, and processing, detecting people and objects in real time.

Compared to a shuttle table system, the V353 offers greater buffering capacity and reduced operator dependency. It enables more continuous, autonomous production. The V353’s moving‑gantry also avoids the size limitations of shuttle tables, allowing greater flexibility in processing larger plates and products.

The V353 processes urgent orders with minimal interrupting ongoing production. Operators prepare an urgent cutting job elsewhere on the bed while the machine continues cutting. The gantry then simply moves to the urgent job, processes it immediately, and then resumes the original buffered job without unloading or re‑measuring, because the plate never moved. Plate buffering, automatic measurement, and rotation eliminate manual handling, enable fast job switching, support just‑in‑time cutting per customer, and significantly reduce sorting effort and labor.

Yes. The V353 allows operators to load and unload sheets while processing buffered jobs, with integrated safety systems continuously monitoring the surroundings to ensure safe operation at all times.

Yes. The V353 is a fiber laser plate processing machine designed to cut mild steel, stainless steel, and aluminum.