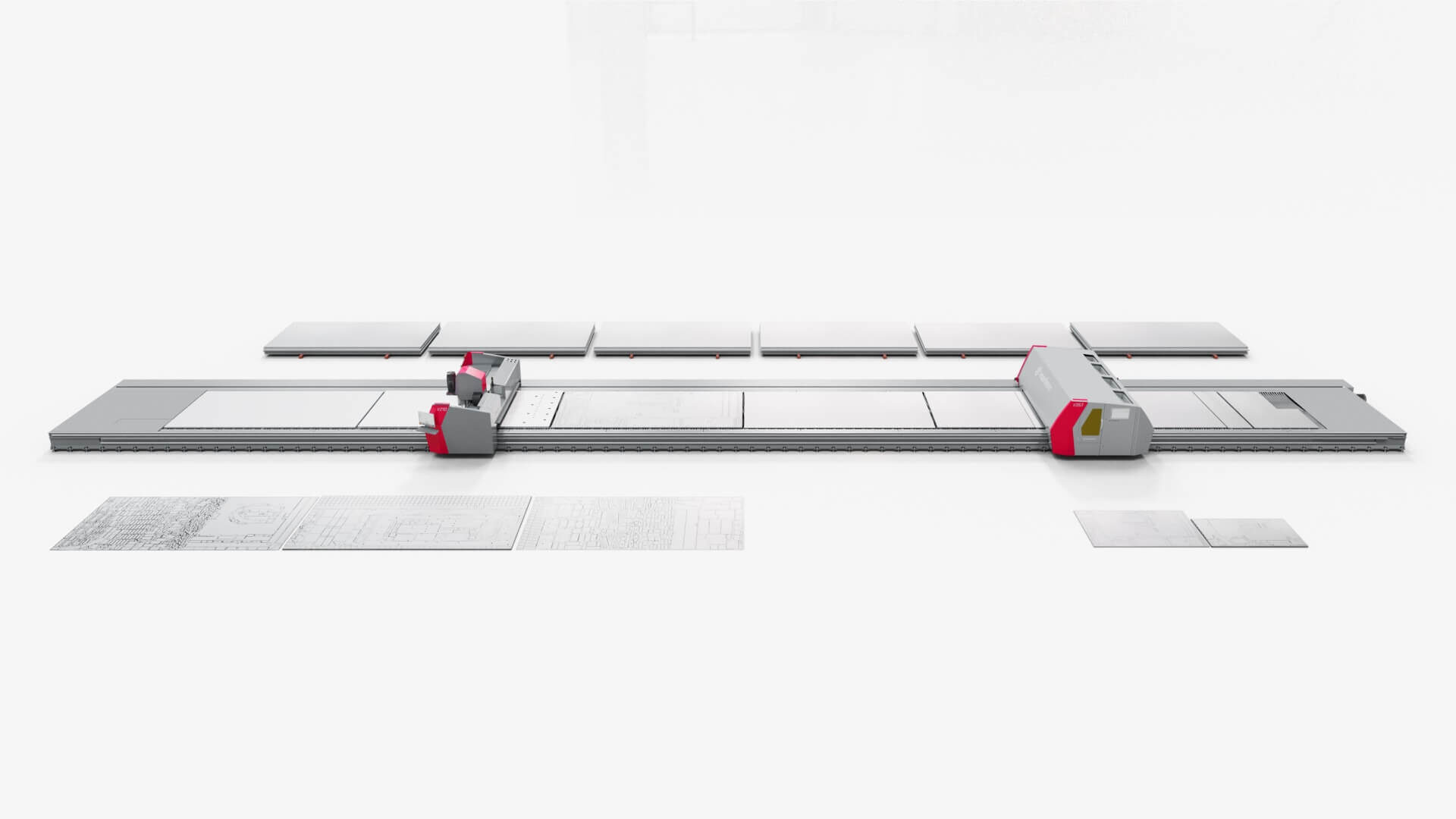

V210

EXTENSION FOR VOORTMAN V353

Combine the speed and precision of laser cutting with the versatility of machining. Add drilling, tapping and milling to the V353 fiber laser plate processing setup with the V210 machining gantry.

- Complete plate processing in one setup: no need to reposition material.

- Maximum versatility: perfect alignment between laser-cut and machined features.

- Faster throughput: fewer handling steps, reduced crane time.

Compatible with:

SigmaNEST | VACAM

OVERVIEW

The Voortman V210 is a plate processing machine. This moving gantry machine complements the V353 fiber laser, without compromising speed and precision, allowing both machines to operate on the same bed. By adding drilling, tapping and milling to the setup, you gain versatility in plate processing and can deliver production-ready products.

The V210 handles plates up to 75 mm (3 inches) thick, drills high-quality holes up to 50 mm (2 inches) with threads up to M30, and offers up to 28 tools with automated selection and advanced software for a streamlined workflow. Engineered for complete plate processing, the V210 extension is ideal for Steel Service Centers and machinery fabricators. Combined with the V353 fiber laser cutting machine it is the ultimate hybrid solution.

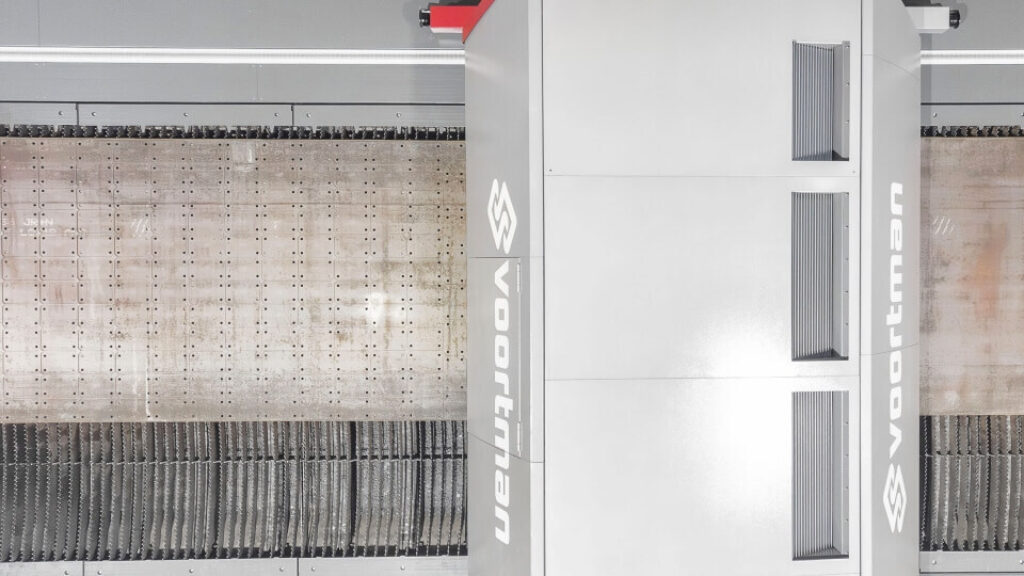

BUILT ON THE PROVEN V310 PLATFORM

The V210 combines trusted machine performance with the added flexibility of laser cutting of the V353. Providing you with powerful spindle for maximum productivity.

BENEFITS

OPTIMAL VERSATILITY

Maintain perfect alignment with all operations on a single bed. Handle both high-mix, low-volume and batch production with the same setup.

HIGH PRECISION & SPEED

Balance high-speed laser cutting with precision machining in one integrated system to achieve maximum accuracy.

SIMPLIFIED WORKFLOW

Switch seamlessly between cutting and machining, without moving the plate(s), for faster throughput and reduced crane time.

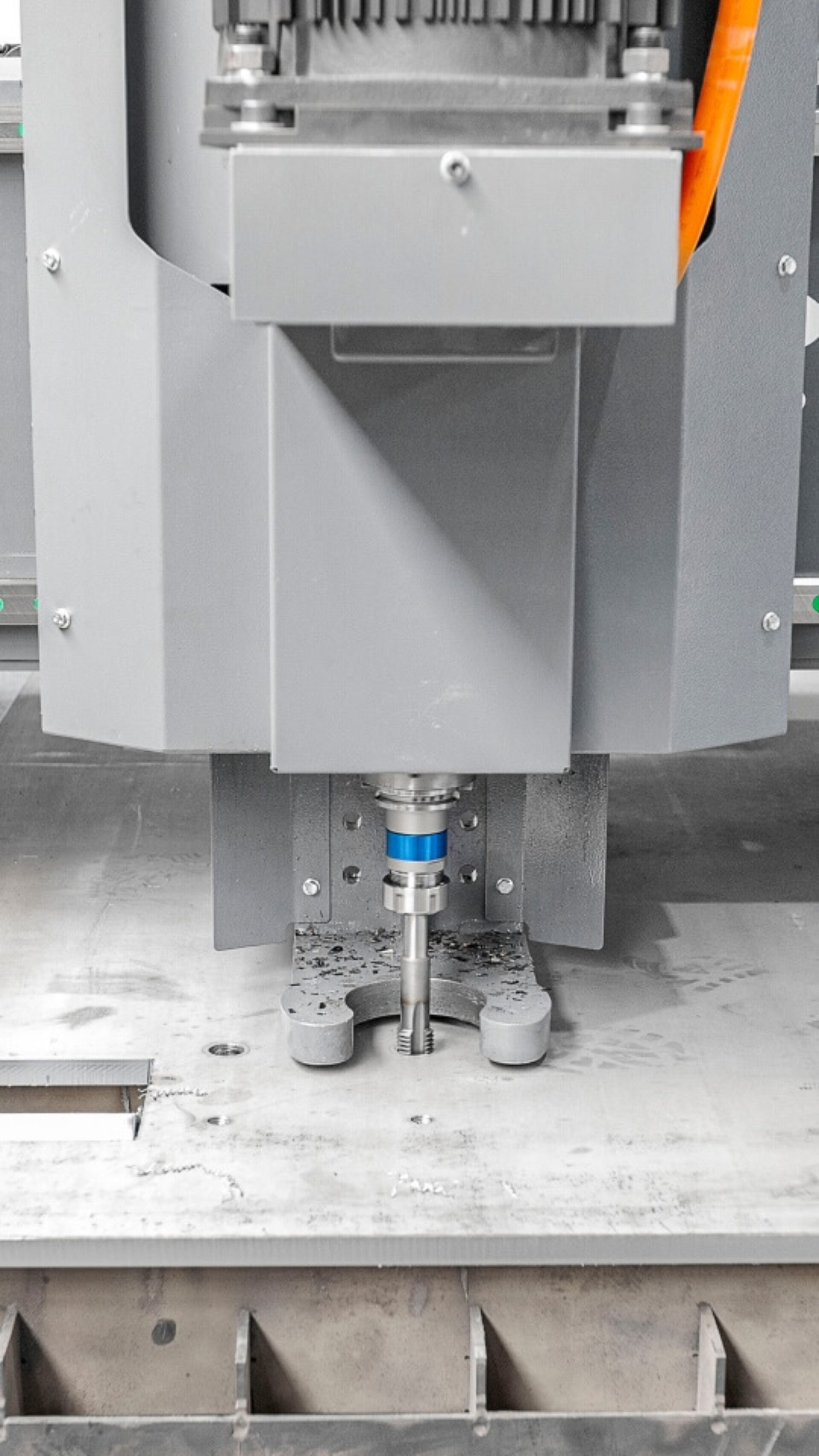

SMART DRILLING & MILLING

High‑stability drill clamps suppress vibration so the high‑torque spindle can apply full power, for better hole quality, longer tool life, and no tip damage.

SPECIFICATIONS

LASER POWER MEETS MACHINING VERSATILITY

The Voortman V353 is a fiber laser cutting machine for large plates. Laser technology delivers high cutting speed and precision while ensuring superior edge quality. When combined with the V210 product extension, you enjoy the advantages of laser cutting as well as the versatility of machining. This complete plate processing setup enables you to create production-ready products, maximize efficiency and support full automation for increased throughput.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.

The V353 delivers all the benefits of laser technology. By adding the V210 extension, you can integrate drilling, tapping, and milling into the V353 plate processing setup, combining laser cutting with machining versatility in a single workflow.

The gantry and bridge are built for heavy drilling. The rigid construction minimizes vibration and maintains stable feed rates—even for deep or large holes. This ensures precision, longer tool life, and consistent performance in demanding drilling and milling tasks.

Voortman provides remote diagnostics, preventive maintenance, and full-service support. Most issues are resolved via the machine interface, minimizing downtime and costs. Regionally stocked spare parts ensure fast response when on-site service is needed.