VOORTMAN V631

OPTIMAL MILLING PERFORMANCE

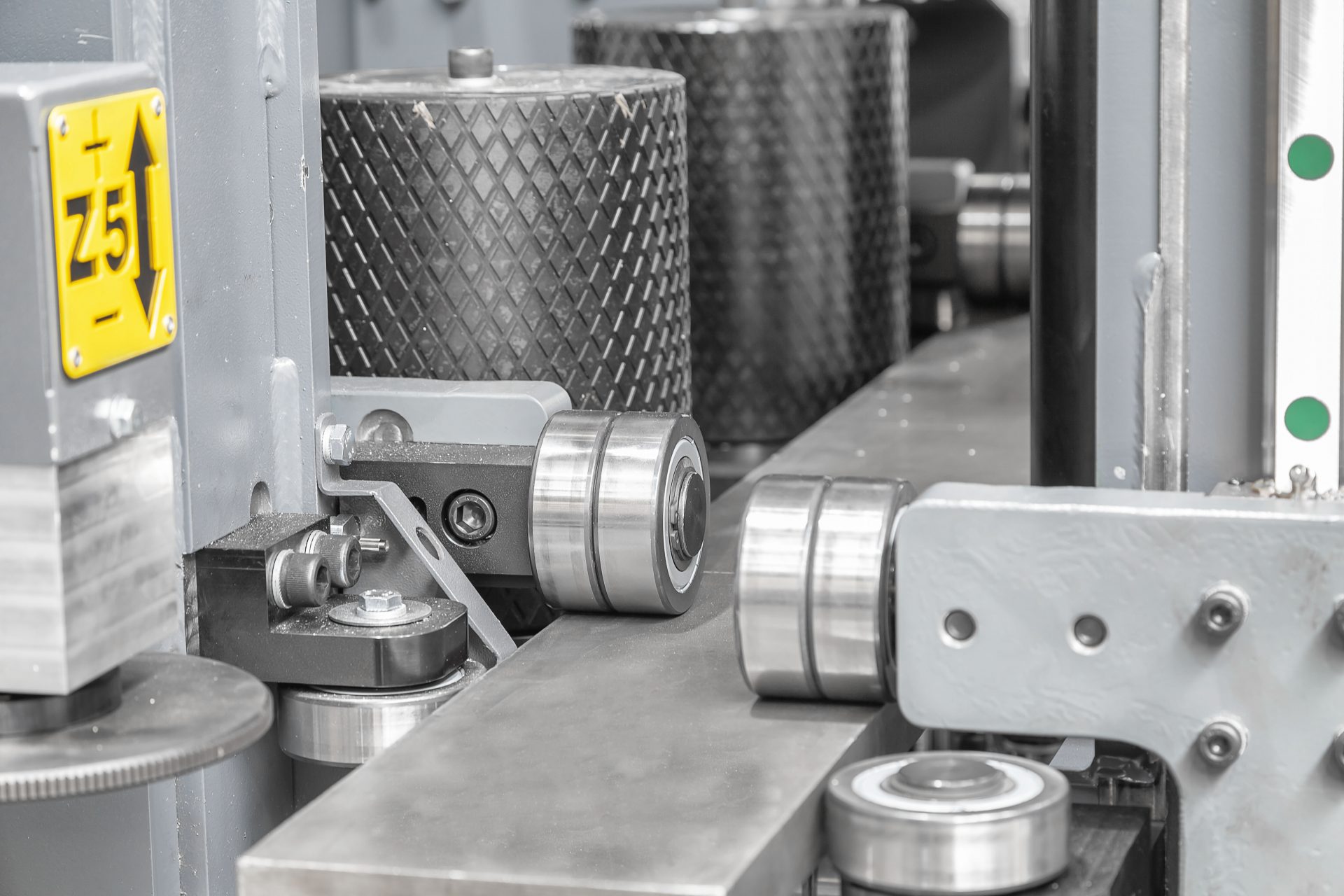

The robust frame, bearings and short tool lengths provide high quality milling with maximum milling speeds and little-to-no vibrations in which this machine guarantees optimal milling performance.

Process for instance oversized holes, slotted holes, block-outs and flange removals on every profile.

FASTEST MILLING

IN THE MARKET

The V631 can boast the fastest milling in the market by using shorter tool lengths, which reduce the distance between the drill and the profile. The shorter the tools, the faster the drill units can move through the material and the longer your consumables will last. Robust bearing and securely mounting the drill units onto the heavy duty frame also helps improve milling speed and quality.

PROCESS ALL PROFILES

The V631 can process the following profiles: I-Beams, H-Beams, Channels, Flat bar, Angle iron, T-bar, Square tubes and Rectangle tubes. These profiles have built-in settings to carry out processing without manual programming in the software, saving you a lot of time. Features are available for handling small profiles and performing more operations automatically, reducing labor costs and lead times for your projects. The V631’s fast gripper truck automatically adjusts the Y-Z position and clamping orientation to properly secure any profile.