CNC MITRE BAND SAWS FOR STRUCTURAL STEEL HIGH-SPEED, AUTOMATED PROFILE CUTTING

Looking for a reliable sawing solution for structural steel?

Voortman’s VB series combines precision, durability, and automation to deliver clean cuts and reduced cycle times. From the VB Standard for everyday use to the Performance series for high-speed production, our saw machines are designed to fit your workflow and integrate seamlessly into automated lines.

REQUEST MORE INFO EXPLORE MACHINES

MITRE SAW CUTTING MACHINES

Voortman offers two series of CNC band saws to meet different production needs. The Standard series provides reliable, precise cutting with essential automation for everyday use, while the Performance series delivers high-speed sawing with advanced automation for maximum throughput and accuracy. Both are designed for clean cuts, mitre flexibility, and seamless integration into automated lines.

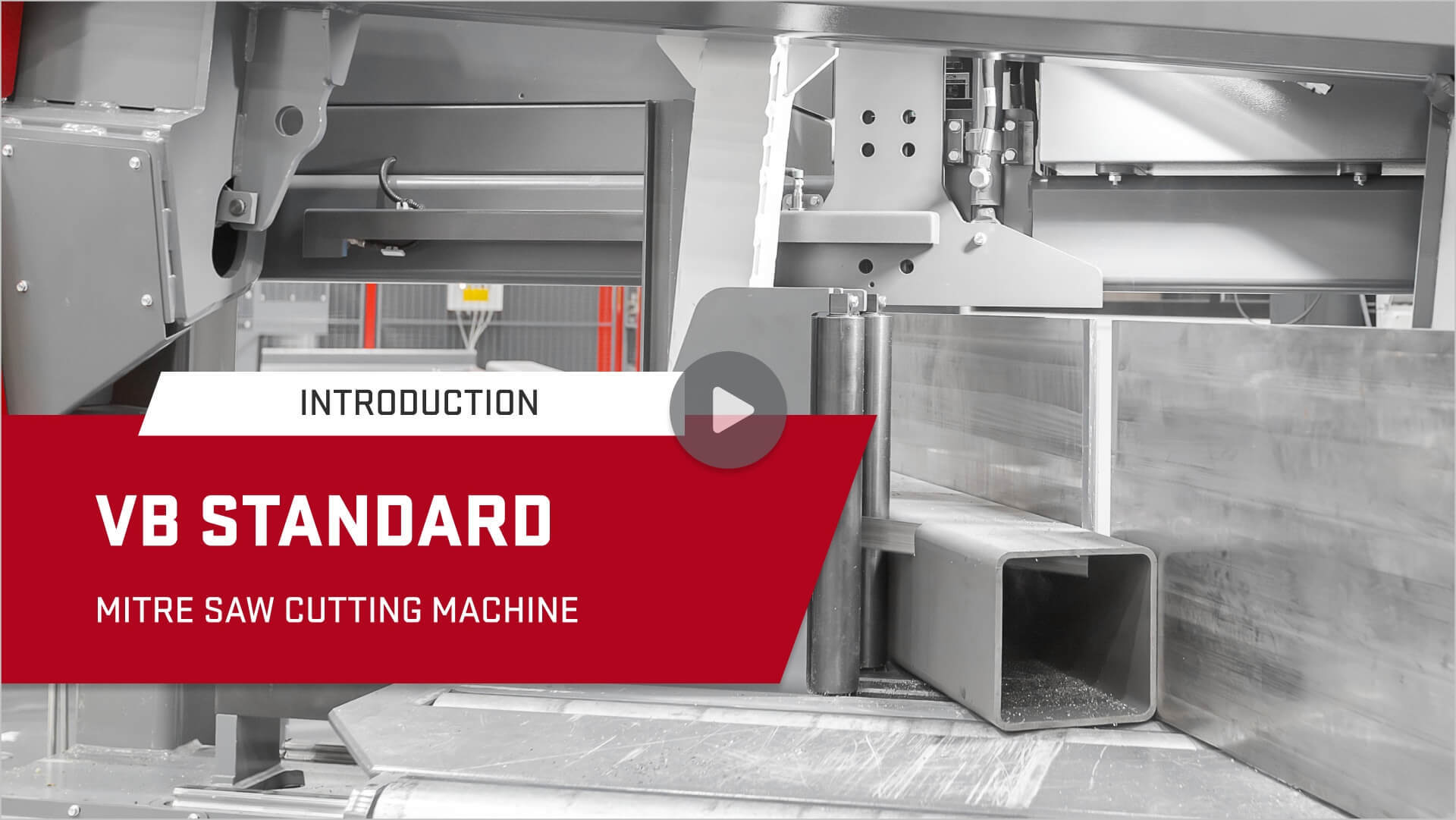

VOORTMAN VB STANDARD

The VB Standard series offers robust, reliable sawing for everyday use. With a double-angled frame, integrated cut kit, and precision feed control, it ensures accurate cuts, reduced cycle times, and extended blade life.

- Type: CNC band saw for structural steel

- Material: H, I, U, T, L profiles, square tube, and flat bar

- Processing Range: Width up to 1,140 mm (44"), Height up to 460 mm (18")

- Processing Capabilities: Straight and mitre cutting up to 60°, automatic feed control, carbide blade guides

- Automation: VACAM software, integrated cut kit, precision feed control

VOORTMAN VB PERFORMANCE

The Performance series is built for high-volume operations that demand speed and accuracy. With advanced automation and uninterrupted sawing, these machines maximize throughput and integrate seamlessly into fully automated production lines.

- Type: CNC band saw for structural steel

- Material: H, I, U, T, L profiles, square tube, and flat bar

- Processing Range: Width up to 1,250 mm (49"), Height up to 600 mm (23")

- Processing Capabilities: High-speed straight and mitre cutting, advanced clamping systems, uninterrupted sawing

- Automation: VACAM software, MSI-ready, optimized clamping and measuring systems

MANUAL VS AUTOMATED SAWING

WHY CHOOSE AN AUTOMATED SAW OVER A MANUAL SAW

Switching from a manual saw to an automated CNC band saw significantly improves both efficiency and quality in fabrication. By automating the cutting process, you eliminate the need for constant operator input, which reduces human error and ensures consistent, high-precision cuts every time.

- Cycle times are much shorter, thanks to automatic feed control and optimized cutting sequences.

- Labor costs and material waste are reduced, as the system works more efficiently and accurately.

For companies handling high volumes or complex profiles, automation is essential to stay competitive and meet tight deadlines without compromising quality.

CHOOSING PRECISION: A COMPARISON OF MEASURING SYSTEMS

Accurate measuring is key to achieving perfect cuts, and Voortman offers several integrated systems to match different production needs. Each system ensures precision, flexibility, and seamless integration with Voortman saws.

- The Gripper Truck provides absolute positioning by clamping and moving profiles with high precision, ideal for heavy-duty automation and high-speed lines.

- The Full-Stop System ensures exact positioning before each cut, delivering repeatable accuracy for semi-automated setups.

- The Pusher System is a cost-effective solution for compact layouts or smaller profiles, maintaining alignment and reducing manual handling.

Together, these systems give fabricators the tools to optimize accuracy, reduce manual effort, and adapt to a wide range of production environments.

COMBINE WITH OTHER VOORTMAN MACHINES

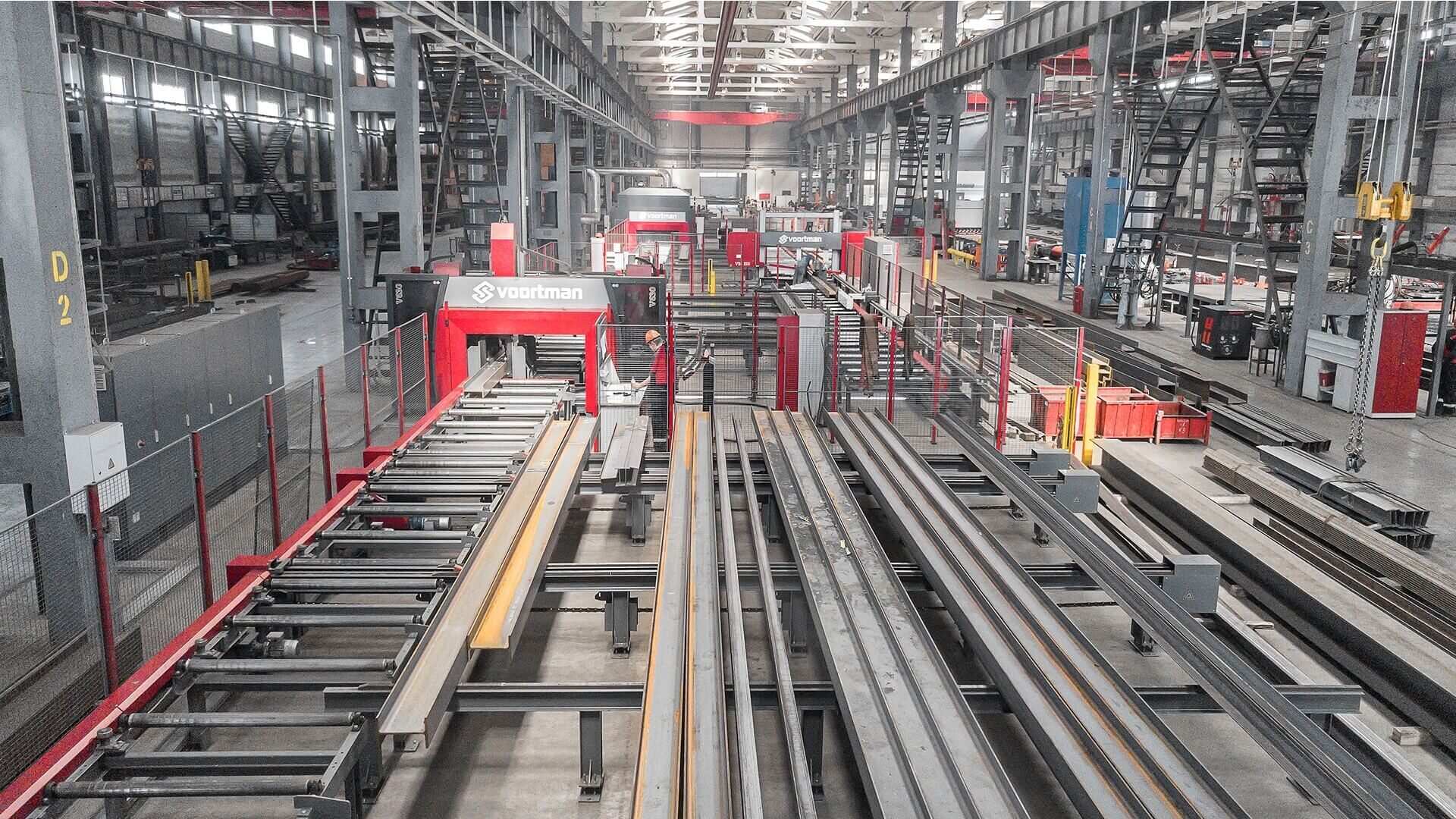

Voortman offers powerful solutions to streamline structural steel processing through intelligent system design. Whether you're aiming for full automation with Multi System Integration (MSI) or seeking compact productivity with a Back-to-Back configuration, both approaches significantly reduce manual handling and increase throughput. These setups are designed to optimize your workflow, minimize downtime, and deliver consistent, high-quality results across your production line.

BACK-TO-BACK

The Back-to-Back configuration combines a Voortman VB bandsaw with a beam drilling machine in a compact layout, sharing a single measuring system. This setup allows both machines to operate in tandem, reducing material handling and increasing throughput. It’s especially effective for fabricators who need to drill and saw in quick succession, as profiles are clamped only once and processed continuously. The shared measuring rolls streamline operations and save valuable floor space, making Back-to-Back an efficient solution for integrated beam processing.

FULLY AUTOMATED SAWING WITH MSI INTEGRATION

For fabricators aiming for maximum efficiency, Voortman’s Multi System Integration (MSI) connects saws, drills, and other machines into one intelligent production line. MSI uses VACAM software to coordinate material flow, optimize cutting sequences, and prevent bottlenecks, while LogicSteel MRP provides full control over planning and scheduling. This integration transforms your workshop into a smart factory, reducing manual work, increasing throughput, and delivering consistent, high-quality output from raw material to finished product.

INTERESTED?

Get in touch with us

We'd love to hear from you! Whether you have questions, need support, or want to learn more about our products and services, our team is here to help.