RAZOS ENGINEERING - Becoming more efficient and cost-effective

"The service that we’ve had throughout has been exceptional.”

Steve Razos

CO-Owner Razos Engineering

Inspired by this testimonial?

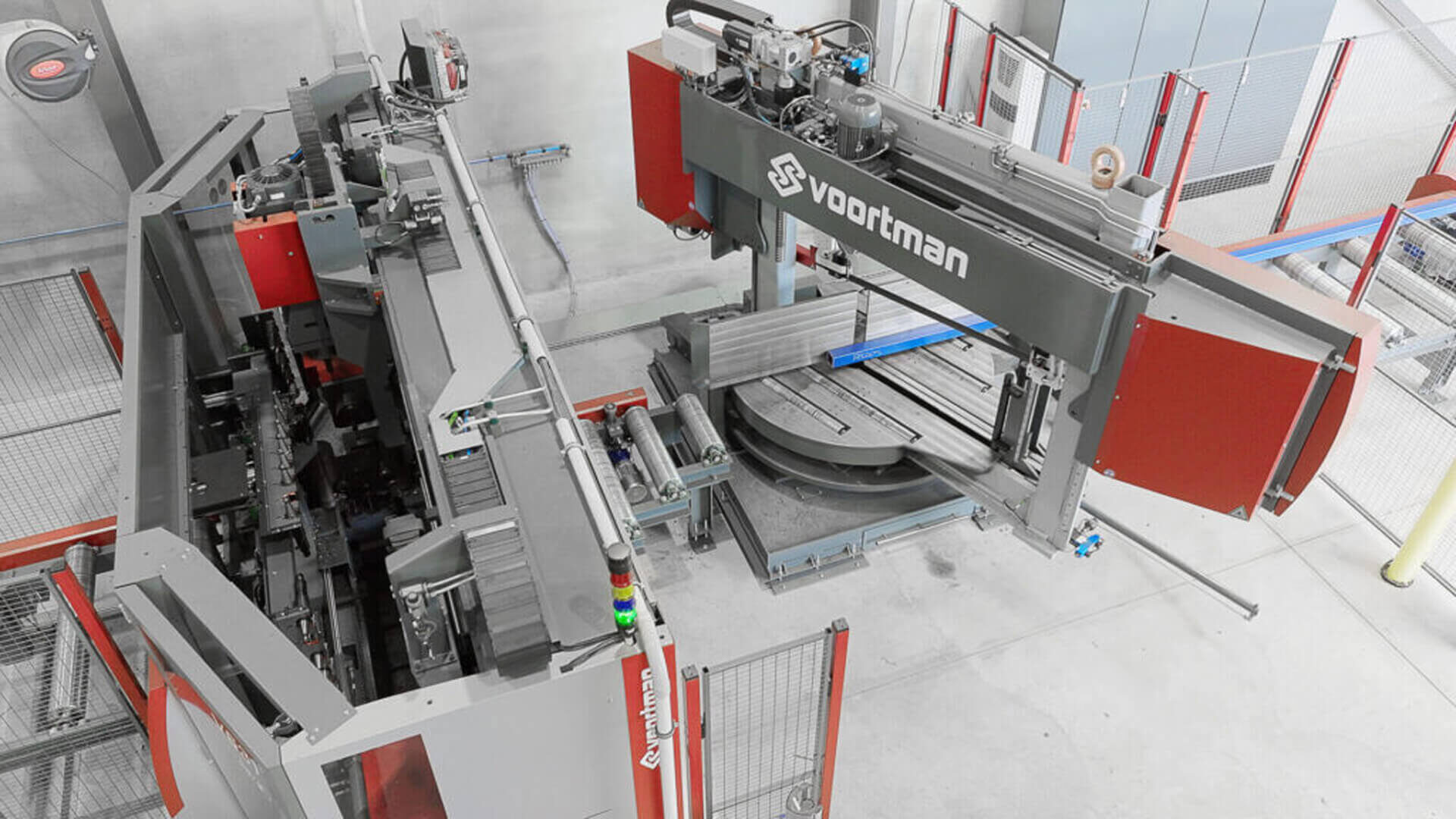

REFERENCED PRODUCTS

THE CHALLENGE

Razos Engineering relied on manual processes, which slowed operations and limited efficiency. To grow the business further, they wanted to increase their processing capacity. They began searching for an automation partner that could scale with them. Steve Razos and his team traveled across the globe to explore different technologies and suppliers, determined to find the right fit. Their goal? Streamline production and become more efficient and cost-effective.

ABOUT THE COMPANY

Razos Engineering is a family-owned business in Hastings, New Zealand. It specializes in structural steel fabrication and earthquake strengthening. With the goal of becoming more efficient and cost-effective, the company knew it was time to evolve. They set out to streamline their processes and invest in automation. This journey ultimately led them to Voortman.

BACK-TO-BACK DRILL/SAW LINE

Razos Engineering decided to invest in a Voortman back-to-back drill/saw line to improve their workflow and take the next step in automation. Voortman offered a V631 and VB1050 in a B2B (back-to-back) configuration, specifically designed to maximize workflow in their factory. This solution gives Razos Engineering the flexibility to handle a wide range of projects and the capacity to grow.

The V631 is a high-speed beam drilling and milling machine, capable of simultaneously drilling and marking all sides. It delivers fast, efficient processing to accelerate production. The VB1050 is a high-performance bandsaw that enables automated straight and miter cutting. Placing the V631 and VB1050 back-to-back significantly boosts productivity, efficiency, and accuracy. The control software VACAM ensures both machines work with precise specifications.

“The product, the service, everything has been exceptional. We’re very happy.”

Steve Razos, CO-Owner Razos Engineering

NEW POSSIBILITIES

The results have been promising for Razos Engineering. The new equipment has opened the door to new opportunities. Razos is now well positioned to take on more clients and larger projects as the region grows. Everything has met their expectations from the start. Delivery was on time, and the machines perform as promised. There have been no major issues. The experience so far has been smooth and impressive. The new setup has made work easier for the team. It’s already helping to boost productivity and profit.

MORE TESTIMONIALS