HOGESNELHEIDS CNC-BALKBOORMACHINES VOOR CONSTRUCTIESTAAL EN MAXIMALE PRODUCTIE

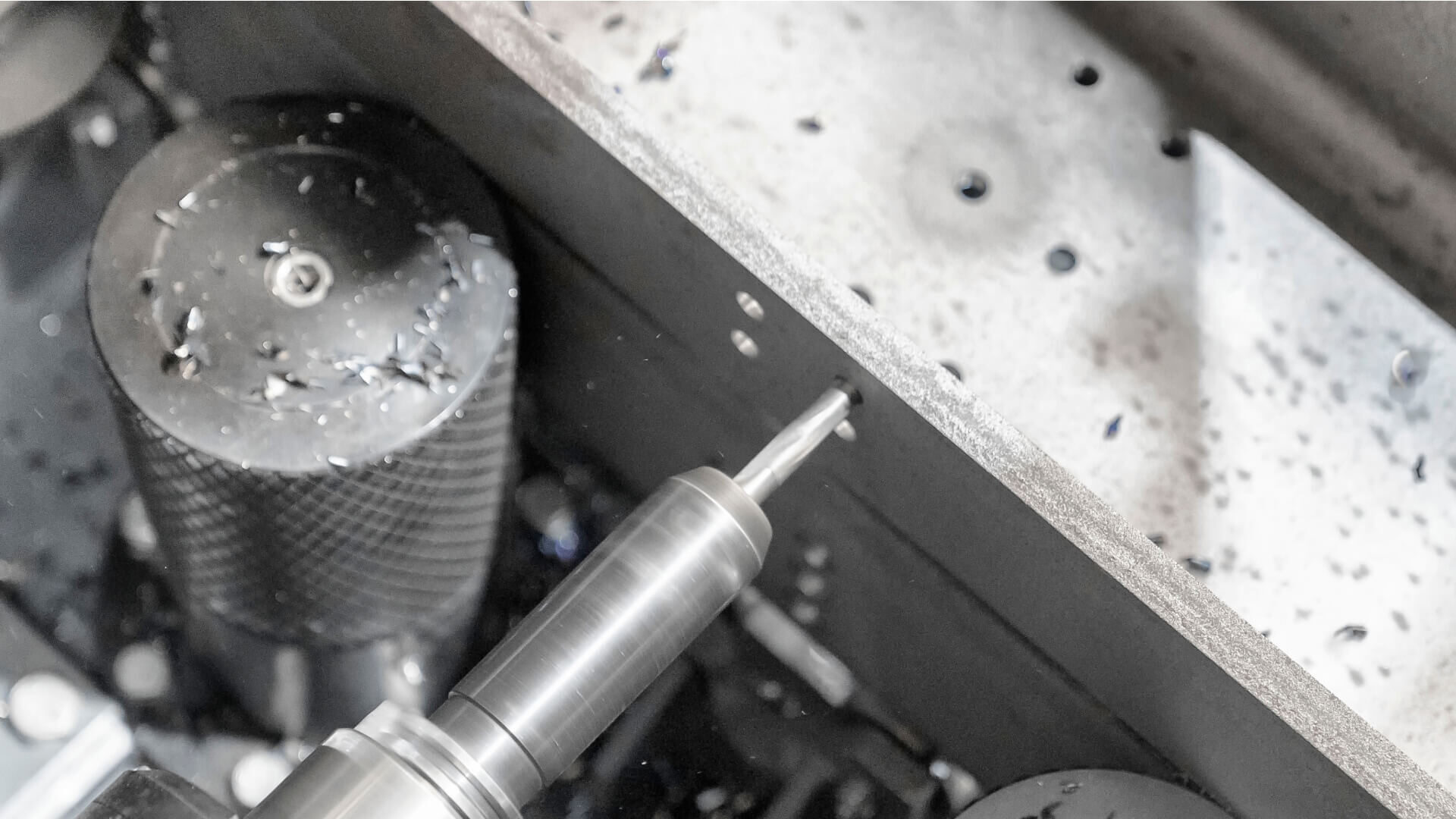

Op zoek naar snel en nauwkeurig boren voor constructiestaal?

Bent u op zoek naar een hoogwaardige CNC-boormachine voor constructiestaal? Voortman biedt een compleet assortiment balkboormachines die zijn ontworpen voor maximale output, automatisering en nauwkeurigheid. Of u nu I-profielen, H-profielen, U-profielen of buizen verwerkt, onze machines leveren lasklare profielen in één bewerkingscyclus. Van standalone boormachines tot volledig geïntegreerde productielijnen: de V630, V631 en V633 zijn ontwikkeld om te automatiseren, productie te verhogen en processen te vereenvoudigen.

BALKBOORMACHINES

VOORTMAN V630

De Voortman V630 is een compacte krachtpatser voor het boren van constructiestaal. Met drie onafhankelijk werkende boorkoppen en automatische gereedschapswisselaars voert hij boren, frezen, draadtappen en markeren uit in één bewerkingscyclus. VACAM en LogicSteel software automatiseert productie en nesting, vermindert operator interventie en verhoogt de output. Ideaal voor fabrikanten die betrouwbaarheid en efficiëntie zoeken binnen een compact design.

- Type: CNC-balkboor- & freesmachine

- Materiaal: H-, I-, U-, T-, L-profielen, vierkante buis en vlak

- Bewerkingsbereik: Breedte tot 1.140 mm (44")

- Bewerkingsmogelijkheden: Boren, frezen, verzinken, draadtappen, nummeren, lay-outmarkering en middelpuntmarkering, binnen- en buitencontouren

- Automatisering: Volledig autonoom

- Kenmerken: 3 spindels, 3 x 6-stations gereedschapswisselaar, integratie van VACAM en LogicSteel software.

VOORTMAN V631

De Voortman V631 biedt het snelste frezen op de markt met een materiaalverwijderingssnelheid van 290 cm³/min en toerentallen tot 4.500 rpm. Elke boorkop ondersteunt tot 8 tools, waardoor volledige multi-procesautomatisering mogelijk is. Gebouwd met hoogwaardige componenten en integratie van VACAM en LogicSteel software, garandeert hij hoge nauwkeurigheid, meer automatisering en langdurige betrouwbaarheid. Perfect voor staalconstructiebedrijven met hoge productievolumes.

- Type: CNC-balkboor- & freesmachine

- Materiaal: H-, I-, U-, T-, L-profielen, vierkante buis en vlak

- Bewerkingsbereik: Breedte tot 1.050 mm (41") of 1.250 mm (50")

- Bewerkingsmogelijkheden: Boren, frezen, verzinken, draadtappen, nummeren, lay-outmarkering, binnen- en buitencontouren & lasvoorbereiding/ratholes

- Automatisering: Volledig autonoom

- Kenmerken: 3 spindels, 3 x 8-stations gereedschapswisselaar, VACAM en LogicSteel software voor geoptimaliseerde sequenties en rol-aanvoer of grijptruck voor profielmeting

VOORTMAN V633

De Voortman V633 is de snelste in de industrie voor gelijktijdige meerzijdige bewerking. Met vier sub-assen, toerentallen tot 5.000 rpm en geavanceerde klemsystemen levert hij ongeëvenaarde doorvoer voor veeleisende productieomgevingen. Ideaal voor grootschalige, geautomatiseerde staalproductielijnen.

- Type: CNC-balkboor- & freesmachine

- Materiaal: H-, I-, U-, T-, L-profielen, vierkante buis en vlak, inclusief kleine profielen vanaf 50 mm

- Bewerkingsbereik: Breedte tot 1.140 mm (44")

- Bewerkingsmogelijkheden: Boren, frezen, verzinken, draadtappen, nummeren, lay-outmarkering en middelpuntmarkering, gelijktijdige binnen- en buitencontouren & lasvoorbereiding/ratholes

- Automatisering: Volledig autonoom

- Kenmerken: 3 spindels met slag in X 300 mm (11 13/16"), 3 x 14-stations gereedschapswisselaar, VACAM en LogicSteel software voor volledige automatisering, servo-aangedreven sub-assen voor meerzijdige bewerking.

MEETSYSTEMEN

Precisie die prestaties aandrijft. Nauwkeurig meten is de sleutel tot perfect boren en zagen. Voortman biedt twee geavanceerde opties: een grijperwagen voor zware profielen en hoge-snelheidsautomatisering, en meetrollen voor continue nauwkeurigheid in realtime in compacte opstellingen. Beide garanderen precisie en flexibiliteit voor elke productiebehoefte.

GRIJPERWAGEN / AANVOERWAGEN

Klemt en verplaatst profielen met absolute precisie. Ideaal voor hoge-snelheidsautomatisering en zware profielen, verkort cyclustijden en garandeert herhaalbare nauwkeurigheid.

MEETROL / AANVOERROLLEN

Biedt continue meting tijdens de aanvoer voor nauwkeurigheid in realtime. Perfect voor kleinere profielen en compacte lay-outs, elimineert handmatige meting en minimaliseert fouten.

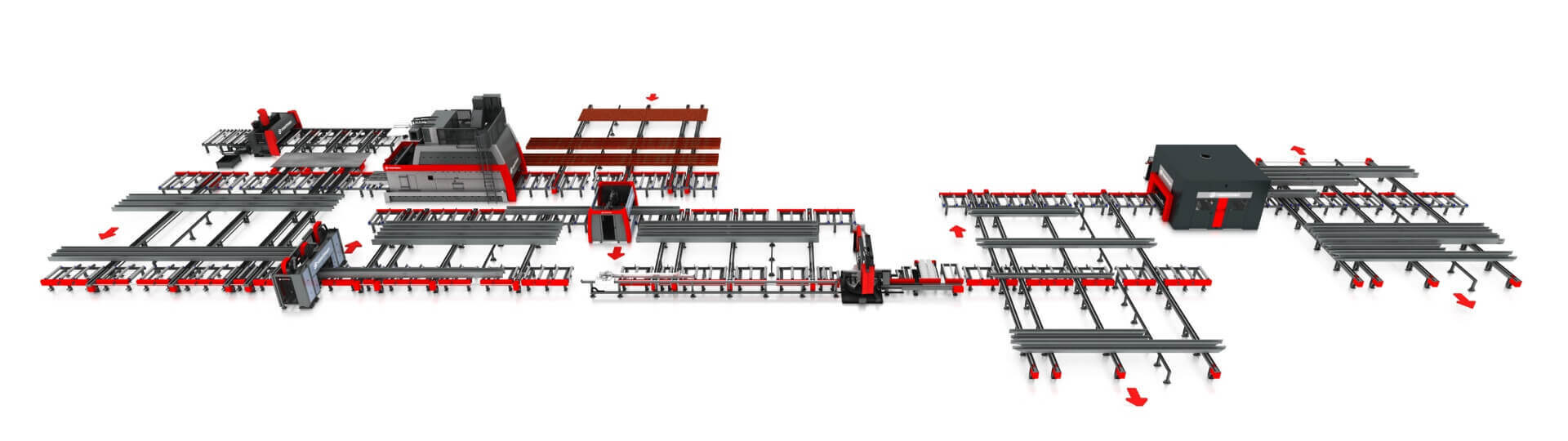

VAN BOREN TOT ZAGEN: RUG AAN RUG EFFICIËNTIE

Stel u voor dat u profielen boort en zaagt zonder ze tussen afzonderlijke machines te hoeven verplaatsen – de Voortman Back-to-Back Drill Saw Line maakt dit mogelijk door de V63x boormachine en de VB bandzaag te integreren in één samenhangend systeem. Met slechts één meting worden zowel het boren als het zagen uitgevoerd in een continue stroom, waardoor de handelingstijd aanzienlijk wordt verkort en de noodzaak voor extra kraanbewegingen wordt geëlimineerd. Deze compacte configuratie bespaart niet alleen waardevolle vloerruimte, maar biedt ook snelheid en precisie – een ideale oplossing voor werkplaatsen die hun efficiëntie willen vergroten zonder hun indeling uit te breiden.

SLIMME FABRIEKEN GEMAKKELIJK GEMAAKT

Voor staalconstructiebedrijven en distributeurs die volledige automatisering (industrie 5.0) nastreven, biedt Voortman’s Multi System Integratie (MSI) een transformerende oplossing. Door machines zoals boren, zagen en copingrobots naadloos te verbinden via slimme toevoerrollen en bufferzones, maakt MSI een volledig geïntegreerde workflow mogelijk. Aangedreven door VACAM-intelligentie worden productiegegevens over alle systemen verspreid voor realtime optimalisatie, waardoor handmatig werk drastisch wordt verminderd en de doorvoer aanzienlijk toeneemt. Met LogicSteel MRP krijgen gebruikers volledige controle over hun fabrieksactiviteiten – van 3D-modellering tot uiteindelijke levering – via één platform voor planning, planning en rapportage. Uiteindelijk verandert MSI uw werkplaats in een slimme fabriek, minimaliseert het aantal manuren per ton en zorgt voor een consistente, grootschalige output.

GEÏNTERESSEERD?

Neem contact met ons op

Wij horen graag van u! Of u nu vragen heeft, ondersteuning nodig heeft of meer wilt weten over onze producten en diensten, ons team staat klaar om u te helpen.