WE CREATE HIGH-END STEEL PROCESSING MACHINES WITH INTEGRATED BUSINESS SOFTWARE THAT AUTOMATE AND OPTIMIZE YOUR PRODUCTION PROCESS.

WITH THE BEST CUSTOMER SERVICE.

VOORTMAN IN NUMBERS

WHO WE ARE

Welcome to Voortman Steel Machinery, a name synonymous with innovation, excellence, and a deep commitment to quality. We have grown from modest beginnings into a large global leader, creating unparalleled CNC steel processing machinery with integrated business software solutions that automate and optimize your production process.

WHAT DRIVES US

It's simple: Your needs and exceeding them. Our mission extends beyond just the machine; we engineer complete solutions. And we do this with a promise of the best customer service, treating each project and customer as a part of our extended Voortman family.

HOW IT ALL STARTED

“It's my privilege to share the story of our company, a journey that is close to my heart and woven into our family business. It all began in a humble chicken shed in The Netherlands back in 1968. The vision and hard work of my father laid the foundation for what Voortman is today.

Those early days were full of pioneering spirit and innovation. We initially focused on building steel structures, a venture that demanded not only skill but also a vision for the future. By the 1995s, our ambitions had grown, leading us to develop steel processing machines — a significant leap that marked the beginning of a new chapter: Voortman Steel Machinery.

Over the years, our company has evolved into a global leading manufacturer of CNC steel processing machinery and software solutions, catering to diverse industries. I am proud to say that we have installed countless machines worldwide. Our journey, marked by milestones and partnerships, wouldn't be possible without our valued customers and talented employees. Their dedication, expertise, and passion have been pivotal in every step of our progress.

I invite you to explore the key moments of our journey, which are not just achievements but also represent the trust and relationships we have built with our customers and partners.

Thank you for being a part of our story or just beginning to explore it!”

HOW WE DO IT

Machines + Software + Service = Your total solution partner

Our goal is to be your total supplier – a partner who doesn't just provide equipment, but a complete solution for your industry. As time marches on, we've evolved beyond just being a machine manufacturer; we've become an architect of software solutions. We understand that in the tapestry of modern production, software is not just a thread but a vital lifeline. It's the key to unlocking the full potential of your production process, optimizing every step to perfection.

Envision a situation where every beam, pipe, and plate machine is part of a greater, more intelligent system. This is what we create with our advanced VACAM Software and the comprehensive DIGI-STEEL Software Suite. It's about creating an ecosystem that's intuitive, efficient, and seamlessly connected.

And we don't just stop at providing state-of-the-art machines and software. Our commitment to you includes powerful, localized customer service. We believe that support should be as accessible as it is efficient, ensuring that no matter where you are, we're just a call or a click away. We're here to make things easy for you, ensuring that from the moment you start working with us, your journey is worry-free.

You can benefit from our in-house approach

At the heart of our ethos lies a blend of forward-thinking innovation, commitment to automation, and an unwavering focus on quality. It's not just what we do, but how we do it that sets us apart. We believe passionately in the power of bringing processes in-house – it's our key to being efficient, independence, and consistently excellent.

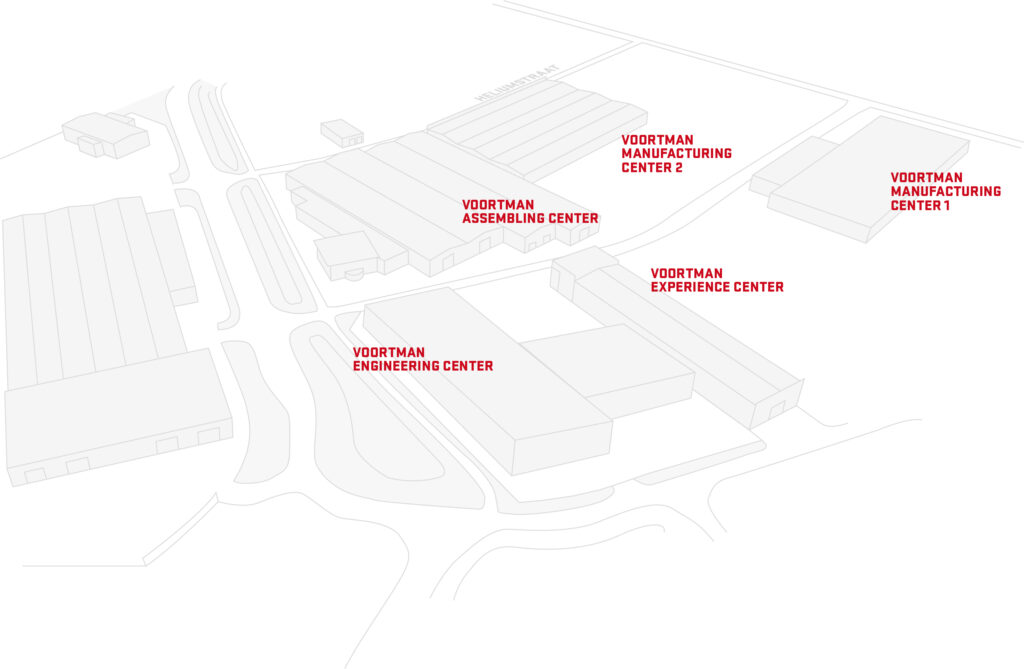

Every building on our large Voortman Campus pulses with a unique aspect of our in-house philosophy. From in-house assembling and thorough testing to in-house production of the robust machine frames and cabinets. We have everything in control, so you know you get a top-notch quality product!

And the best part? We're excited to share this world with you. Join us on a tour of our facilities. We'll pull back the curtain and show you what happens behind those walls, so you can see firsthand the care, expertise, and passion that goes into crafting each of our solutions.

Experience the Voortman Campus / An Exclusive Behind-the-Scenes Look

ㅤ

https://youtu.be/PYVLlZ5vyPU?s...

Voortman Experience Center

Interactive showroom, demo and training center

https://youtu.be/R4j-3L-FJHw?s...

Voortman Manufacturing Center 1

Use our machines to build our machines

https://youtu.be/UGQ17A5FunE?s...

Voortman Manufacturing Center 2

Welding parts together and electrical cabinet production

Interactive showroom, demo and training center

Come visit the Voortman Experience Center

We warmly invite you to our Voortman Experience Center – a space that's more than just a showroom, it's an interactive adventure. Explore our machines up close, choose one that interests you, and we'll arrange a live demo just for you. See innovation firsthand as our machines turn raw materials into masterpieces. Can't visit in person? No problem! Experience it online.

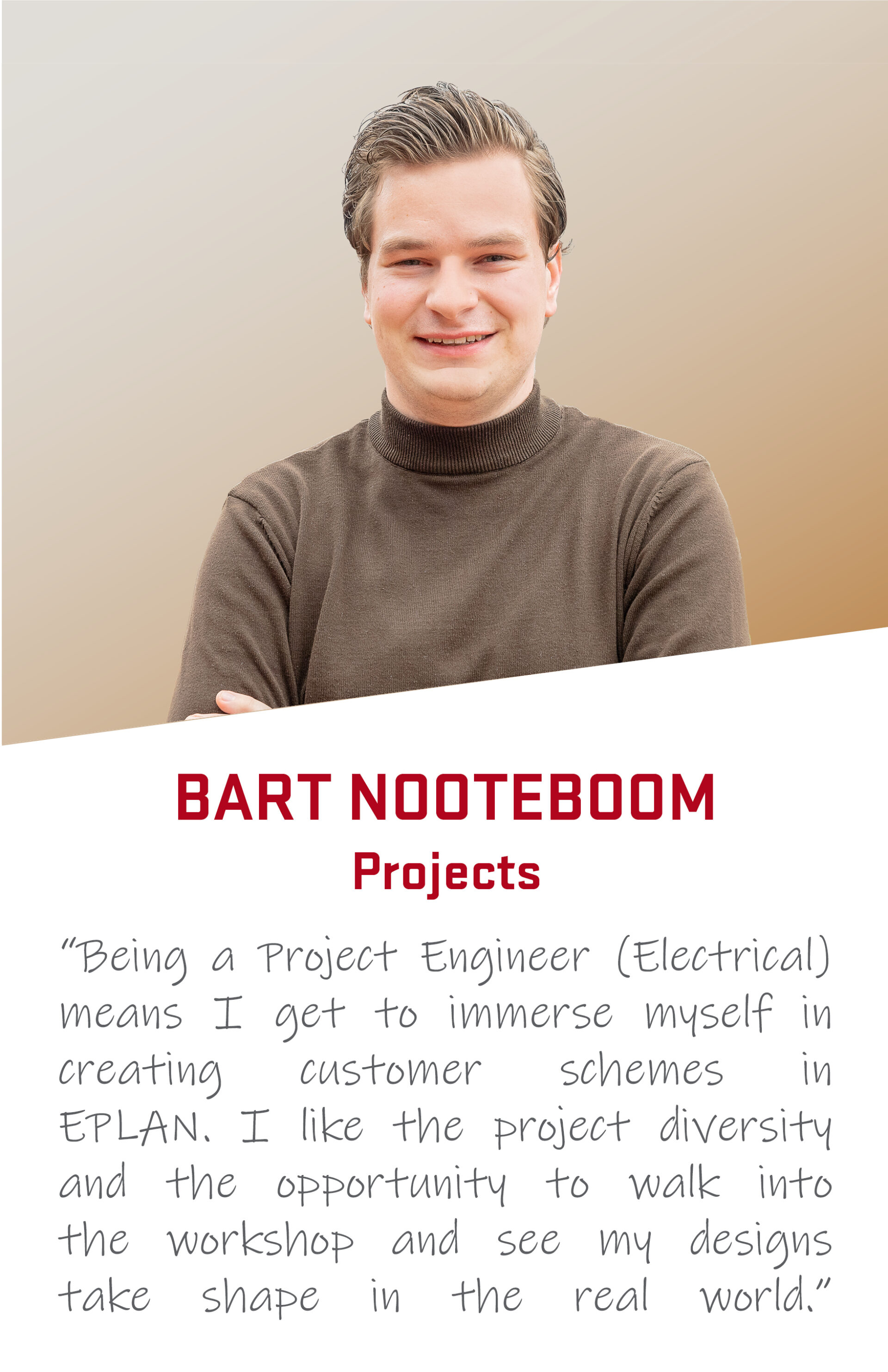

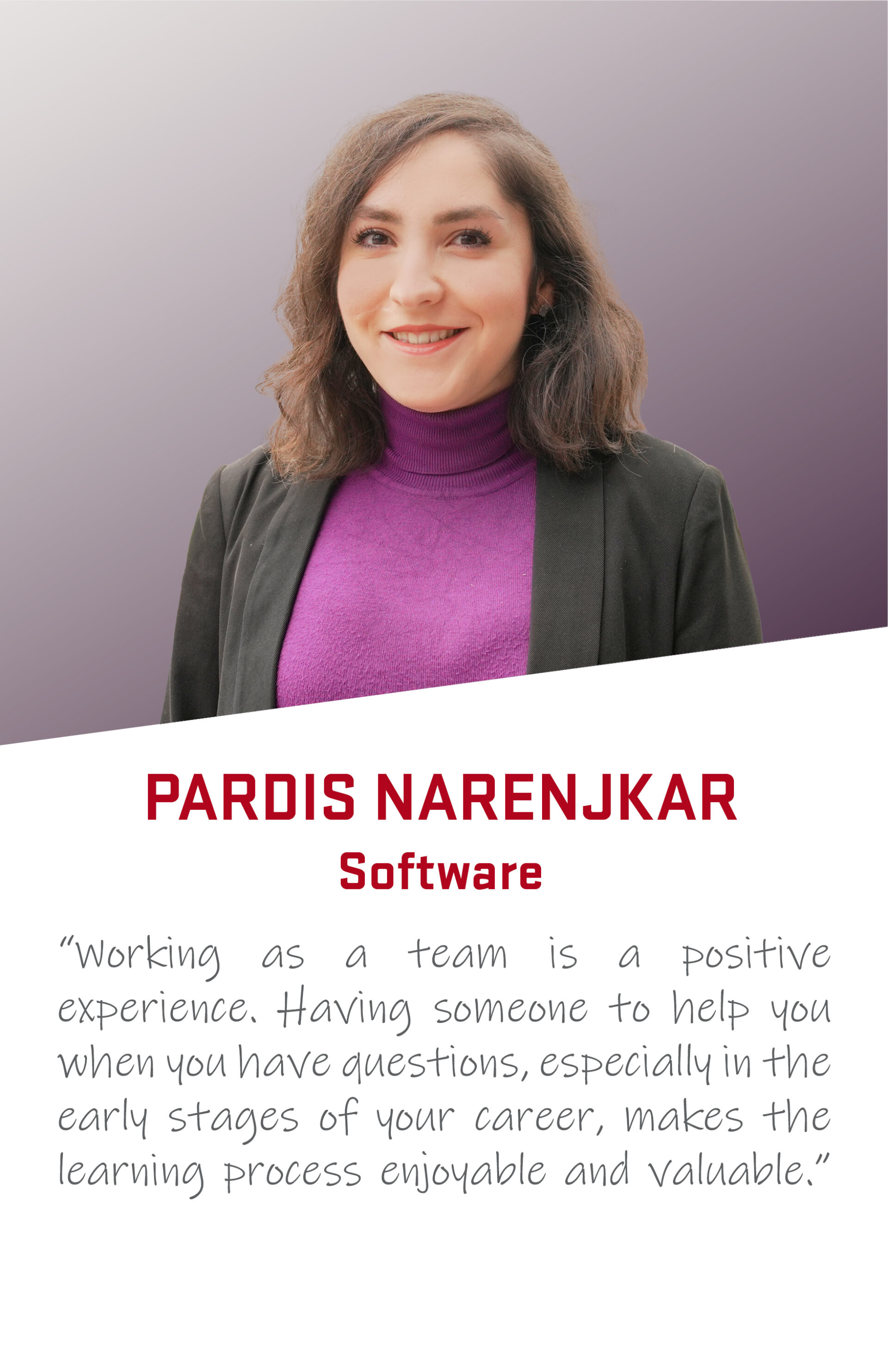

A GLIMPSE OF OUR PROFESSIONALS

At Voortman, we pride ourselves on the diverse and rich experiences of our 600-strong workforce.

Each employee carries a unique story. While it's not feasible to share every individual narrative, we believe it's important to spotlight some of them to give you a glimpse into the Voortman culture that drives us.

THE VOORTMAN JOURNEY CONTINUES, YOURS TOO?

As we look to the future, we are excited about the possibilities that lie ahead. We remain committed to our mission of delivering exceptional value to our clients and playing a vital role in the advancement of the steel processing industry. We continue to innovate, grow, and create lasting impacts across the globe.

But here’s a question for you: What are your plans for the coming 10 years?

Why wait for inspiration when you can find it now, right?

We will help you discover it.

Our monthly newsletter is your personal gateway to a world brimming with exciting developments and exclusive insights. By signing up, you'll not only be at the forefront of industry trends but also be part of a community that values staying informed and ahead of the curve. Don't miss out on this opportunity to enrich your knowledge. Join us today by subscribing to our newsletter and start receiving your monthly dose of inspiration and insight!