Laser cutting machines for tubes

Get the most out of tube processing with Voortman’s advanced laser cutting machine for tubes. Designed for you with accuracy, efficiency, and automation. Our CNC-driven solutions deliver precise cuts for various tube materials, including steel, stainless steel and aluminum. Whether you create structural components, machinery parts, or complex assemblies, you get optimal performance and productivity.

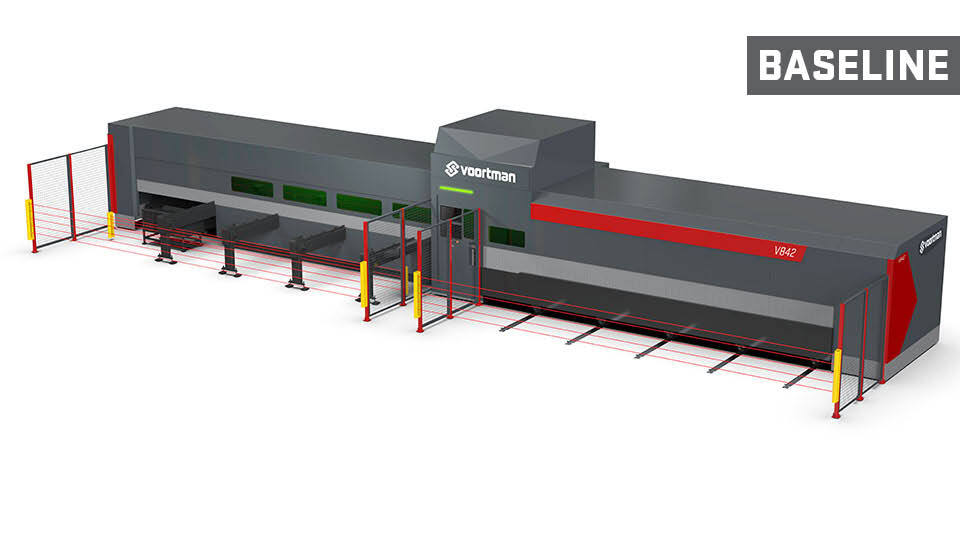

Check out our laser cutting machines for tubes

Why choose Voortman's laser cutting machines for tubes?

- Advanced CNC technology. Easy integration for precise and automated fiber laser tube cutting operations.

- Competitively priced. Entry-level laser cutters with great benefits. Perfect to meet Voortman's quality standards.

- Versatility. Process a wide range of steel materials and thicknesses with Voortman's tube cutters.

- Easy to use. The software on the machines is advanced, but the machines are easy to use. Everybody can be a operator.

- Durability & reliability. Engineered for long-term performance in high demanding environments.

- Backed by Voortman service. Experience world-class Voortman customer service with our global network of subsidiaries, warehouses, and service points. No matter where you are, we are always near you, ensuring prompt assistance.

Endless possibilities with tube laser cutting

Voortman’s laser cutting machines give you the chance to handle a variety of applications with ease. Whether you produce structural frameworks, precision components, or custom designs, you get consistent quality and efficiency. Advanced automation and intelligent software make complex shapes and cuts easy to achieve. This optimizes your production process and reduces waste. No matter the scale or complexity of your operation, you get the precision and reliability you need.

Minimal post processing

Voortman’s laser cutting machines for tubes are designed to minimize post-processing. Unlike traditional plasma cutting, laser cutting leaves no slag and delivers clean edges with precise finishes. That means less cleanup time for your team. They have more time to focus on what really matters.

Infinite chuck rotation

No repositioning. No downtime. Just continuous processing. Our CNC laser cutting machines for tubes come equipped with infinitely rotating chucks. This means long profiles and complex shapes can be cut in one smooth motion with no stops or manual intervention. Spiral cuts? Backside processing? Bring it on. By rotating the profile after each cut, the laser head avoids leftover material, reducing the risk of collisions. That also means fewer nozzle replacements and lower maintenance costs. It’s all about keeping your production flowing and your efficiency high.