V320

PLATENBEWERKINGSMACHINE

Ontworpen voor precisie en productiviteit: de V320 combineert boren en geavanceerde plasmasnijtechnologie met geautomatiseerde materiaalhandling voor efficiënte, nauwkeurige plaatbewerking.

- Maximaliseer de productiviteit met lange, onbemande shifts dankzij automatische gereedschapswissels en soepele afvoer van onderdelen.

- Bespaar tijd en vloerruimte door boren en plasmasnijden te combineren in één geïntegreerd systeem.

- Verminder materiaalverlies en kosten met geavanceerde nestingtechnologie en geminimaliseerde dode zones.

- Neem slimmere beslissingen met een realtime dashboard dat de voortgang van opdrachten en prestatie-inzichten toont.

- Voorkom stilstand tijdens lange runs met automatische spaanafvoer die het snijgebied schoon houdt.

Beschikbare modellen:

2.000 x 6.000 mm | 2.000 x 9.000 mm | 2.000 x 12.000 mm

3.000 x 6.000 mm | 3.000 x 9.000 mm | 3.000 x 12.000 mm

OVERZICHT

De V320 is een geïntegreerd platenbewerkingssysteem dat boren met hoog koppel en geavanceerd plasmasnijden combineert in één geautomatiseerd platform. Uitgerust met een 10-stations gereedschapswisselaar, magnetische toortsmontages en intelligente nestingalgoritmen, zorgt het systeem voor nauwkeurige gatbewerking, geoptimaliseerde snijpaden en minimaal materiaalverlies. Automatische spaanafvoer, een botsveilig ontwerp en de functie ‘snijden hervatten’ leveren continue productie en consistente kwaliteit bij uiteenlopende plaatdiktes.

MACHINES IN DEZE PRODUCTLIJN

SUCCESVERHALEN

We hechten veel waarde aan onze klanten en hun feedback; dat is wat ons drijft om te blijven verbeteren en innoveren. Benieuwd hoe onze machines het verschil maken? Luister naar onze klanten terwijl zij hun ervaringen delen.

TOEPASSINGEN

KENMERKEN

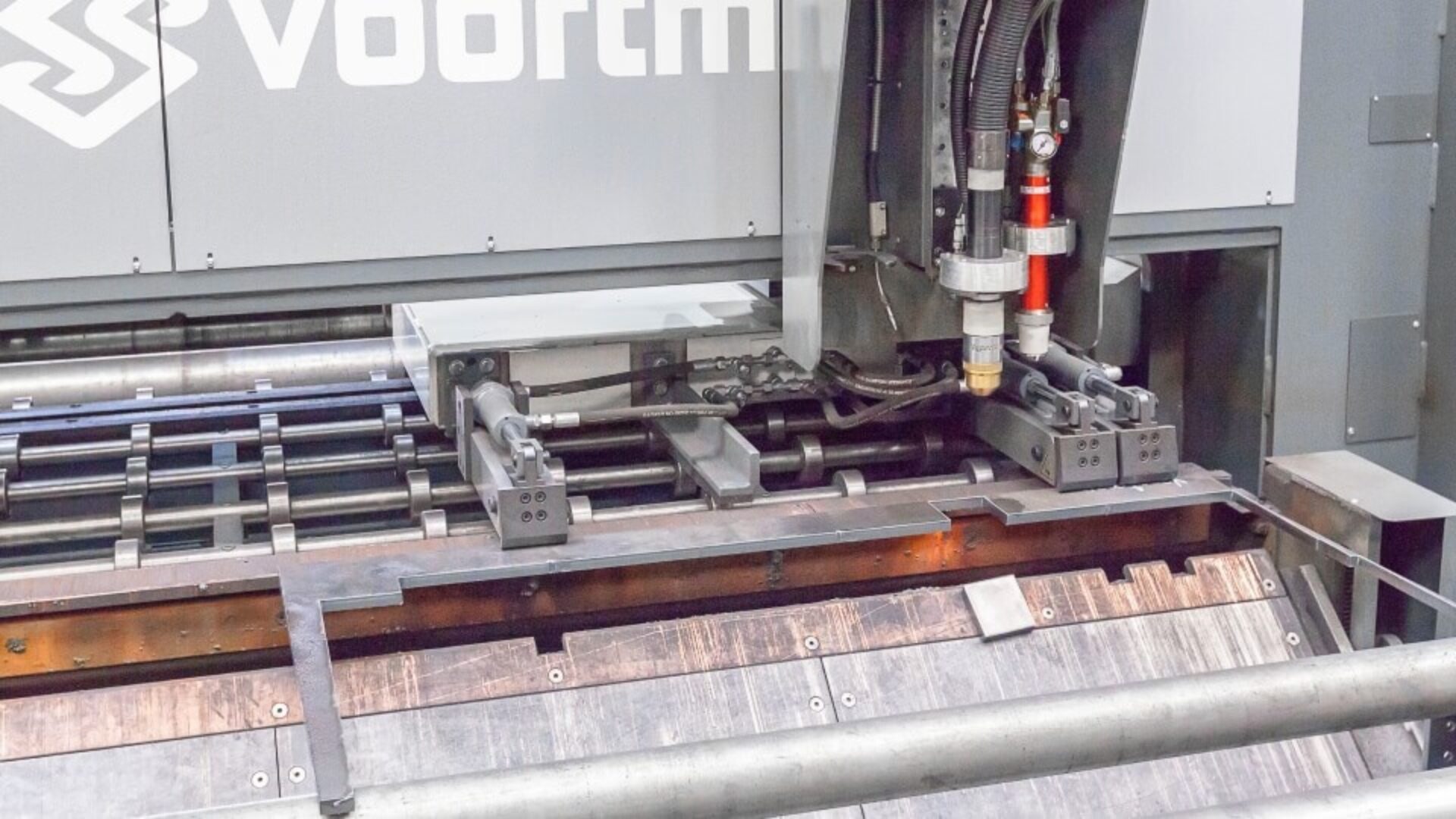

AUTOMATISCHE GEREEDSCHAPSWISSELAAR

Een 10-positie gereedschapsstation elimineert handmatige tussenkomst tussen boorbewerkingen, vermindert stilstand en verlaagt arbeidskosten. Dit betekent hogere output en minder afhankelijkheid van de operator — cruciaal in productieomgevingen met hoge volumes of onbemande productie.

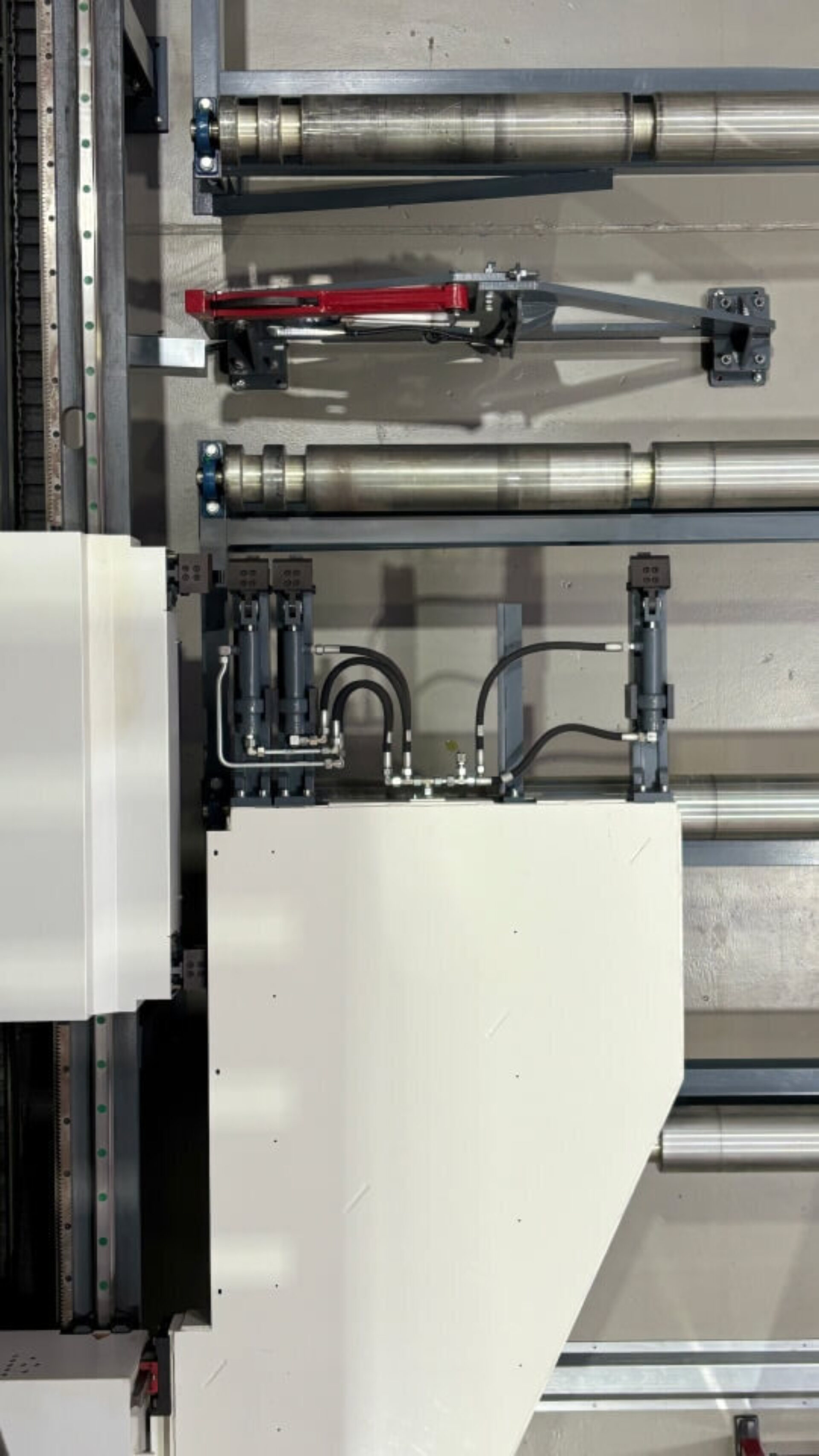

ROBUUST GRIPPERTRUCKSYSTEEM

Sterke achter- en ondersteunende zijwagens: nauwkeurige plaatpositionering en veilige klemkracht minimaliseren dode zones en maximaliseren materiaalyield. Dit resulteert in minder materiaalverlies en betere nesting-efficiëntie — een belangrijke kostenbesparende factor voor constructiebedrijven.

MAGNETISCHE TOORTSMONTAGE

Botsingen zijn onvermijdelijk bij plasmasnijden. Deze functie voorkomt schade en maakt herkalibratie overbodig, bespaart uren onderhoud en voorkomt dure vervangingen — essentieel voor uptime en operationele continuïteit.

VOORDELEN

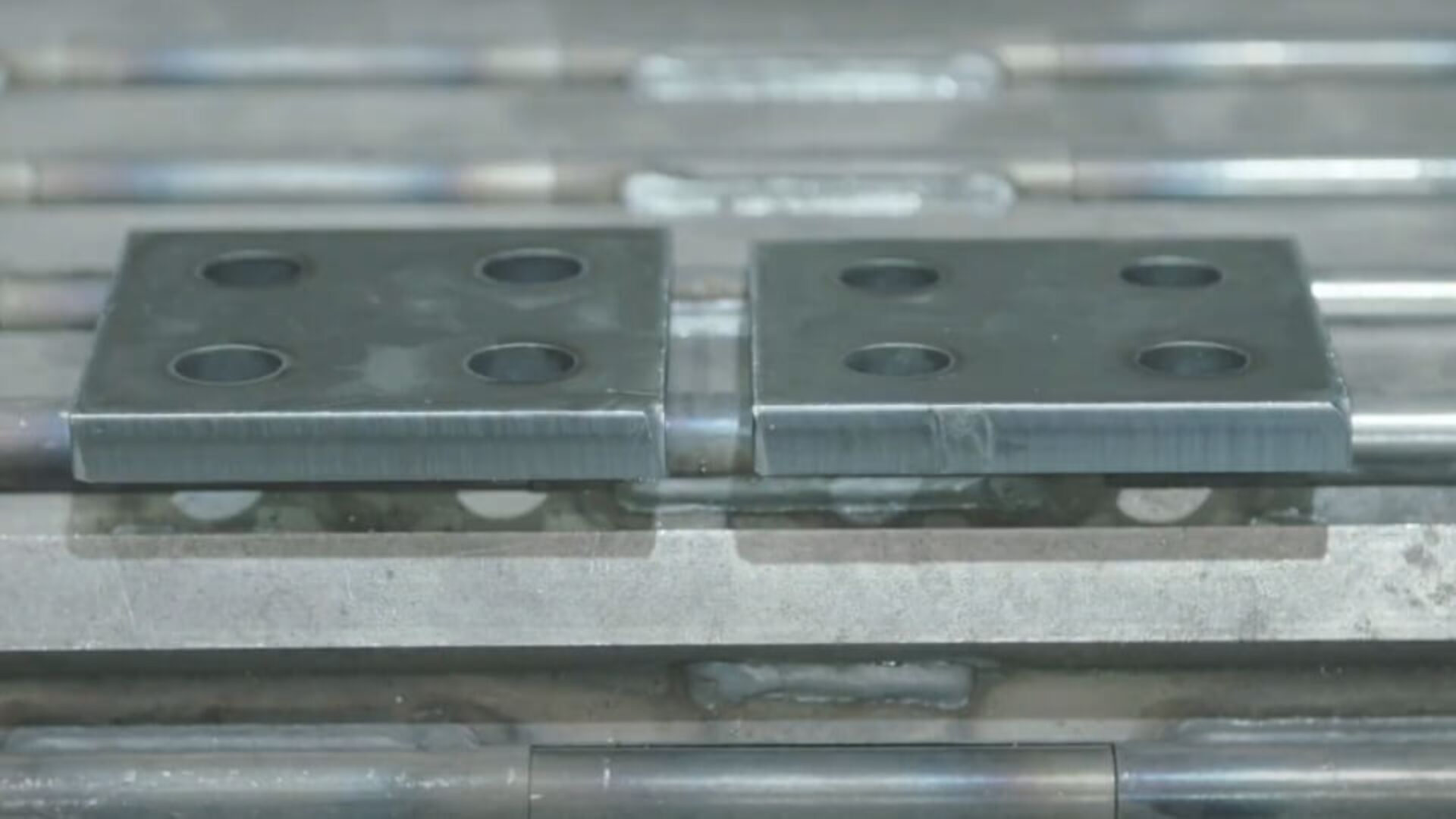

MINDER DODE ZONE

Door de zijgripper in de laatste bewerkingsfase vrij te geven, snijdt de V320 tussen de gripperklemmen door en over de volledige plaat, waardoor dode zones worden geminimaliseerd en het materiaalgebruik toeneemt.

TRANSPORTBAND & VALKLEP

Een 750 mm brede transportband verplaatst producten tot 500 mm diagonaal, terwijl de zware valkleptafel onderdelen snel uitlaadt tot 500 × 500 mm en 75 kg. Dit versnelt afvoercycli en maakt langere onbemande runs mogelijk.

SPAAFAFVOER

Een dubbelwerkende spaanborstel veegt eerst de plaat schoon en maakt daarna een tweede passage om resterende spanen te verwijderen, zodat het plasma niet over vuil snijdt — dit voorkomt defecten en verbetert de snijconsistentie.

STARRE KLEMMING

Hoogstabile boorklemmen onderdrukken trillingen zodat de hoogkoppelspil vol vermogen kan leveren. Dit voorkomt puntslijtage en ‘chatter’ en verbetert zowel gatkwaliteit als standtijd.

BRUGSNIJDEN

Brugverbindingen in het nest ontladen volledige rijen in één keer, verminderen plasma-herstarts en perforaties, en besparen tot 8 seconden per product — lagere verbruikskosten en hogere opbrengst.

HD MULTIDROP-WERKSTROOM

Een sequentiële multi-dropstrategie maximaliseert het gebruik van het plaat‘skelet’ terwijl minder meters worden gesneden, waardoor afval en operationele kosten dalen en materiaalhandling afneemt.

RESTSTUK-NESTING

Plaatverificatie met lasercontourtracering en VACAM auto-rotatie maakt nesting in reststukken mogelijk met één intacte hoek, waardoor materiaalverlies en insteltijd afnemen.

SNIJDEN HERVATTEN

Een eenvoudige UI hervat onderbroken sneden exact op het foutpunt met vrijwel onzichtbare markeringen, minimaliseert stilstand en behoudt snijkwaliteit.

SPECIFICATIES

2000

Werkbereikbreedte

2.050 mm

Maximaal plaatgewicht

7.500 kg

3000

Werkbereikbreedte

3.050 mm

Maximaal plaatgewicht

9.000 kg

Meer informatie nodig?

Download gratis brochures, technische specificaties en productdocumenten voor deze machine. Alles wat u nodig hebt om een weloverwogen beslissing te nemen, is slechts één klik verwijderd.

UPGRADE UW MACHINE

Hydraulische duwers

Hydraulische duwers aan de invoer trekken de plaat met één druk op de knop terug naar de referentielijn, voor snelle, herhaalbare uitlijning en kortere insteltijd.

Dwarsbuffer

Handmatig bediende dwars-transporten zorgen voor een invoerbuffer en kunnen per meter worden uitgebreid, waardoor het laden gelijkmatiger verloopt en stops afnemen.

Hypertherm-plasmabronnen

Kies XPR300- of XPR460-bronnen om de snijsnelheid te verhogen en schone randen te behouden bij dikkere materialen.

Layout-markeergereedschap

CNC-gestuurd krassen van onderdeelnummers en referentielijnen zorgt voor consistente markeringen, snellere setup en minder verwisselingen op de werkvloer.

Uitvoerrollenbaan

Deze kan met 1,5 meter worden verlengd om grotere rest-plaatskeletten en grote platen op te vangen die niet automatisch kunnen worden uitgeladen en handmatig moeten worden uitgeladen. De uitvoerlengte bepaalt de maximale productlengte en kan dus 1,5 m of 3 m zijn.

Load Manager-module

Met de SigmaNEST Load Manager-module hebt u volledige controle over complexe werkorders; de productie kan snel worden beoordeeld en orders kunnen eenvoudig aan elke compatibele machine worden toegewezen.

GEÏNTERESSEERD?

Neem contact met ons op

We horen graag van u! Of u nu vragen hebt, ondersteuning nodig hebt of meer wilt weten over onze producten en diensten: ons team staat voor u klaar.

Schakel de Dross Inhibitor in voor plasma-piercing. Vlak voor het piercen verstuift het systeem een dunne olielaag op het materiaal; de “vulkanische” uitbarsting van gesmolten metaal tijdens het piercen raakt deze laag en kaatst terug in plaats van aan de plaat te hechten. Dit vermindert spetters en slak rond het pierce-punt drastisch en verkort de nabewerkingstijd.

Een spanningsarm, thermisch en mechanisch behandeld portaal vormt een stijve basis, uitgerust met precisie lineaire geleidingen en voorgespannen kogelomloopspillen; in combinatie met direct-drive servo’s, high-resolution encoders, automatische smering en omgevingsbescherming behoudt het systeem de geometrie, minimaliseert het slijtage en blijven toleranties jaar na jaar strak.

Voortman biedt remote diagnostiek, preventieve onderhoudspakketten en volledige serviceondersteuning. De meeste problemen kunnen op afstand via de machine-interface worden opgelost, waardoor stilstand en servicekosten dalen. Reserveonderdelen worden regionaal op voorraad gehouden, zodat er snel kan worden gereageerd wanneer fysieke interventie nodig is.

Hoogwaardige snijkwaliteit vereist frequente hoogtemetingen; bij een typisch onderdeel met vier gaten kan meer dan 30% van de cyclustijd opgaan aan bewegingsgerelateerde controles. Onze ultrasnelle hoogteregeling minimaliseert deze overhead, zodat u de meetfrequentie kunt afstemmen op de gewenste kwaliteit en de maximaal haalbare productietijd benut. Dankzij magnetische montage deelt de oxy-fuel toorts dezelfde snelle hoogteregeling, waardoor zowel plasma als oxy-fuel profiteren van hogere throughput met consistente snijkwaliteit.

Gebruik VACAM’s live tellers voor start-stop-aantallen en totale snijlengte om wisselintervallen in te stellen die passen bij uw kwaliteitsdoelen. Dit houdt de snijkwaliteit consistent, voorkomt te vroege wissels, vermindert scrap en rework, verlaagt uw kostprijs per onderdeel en maximaliseert uptime.

De Voortman V320 combineert een stijve doorvoerarchitectuur met een krachtige boorspindel en servo-aangedreven precisiebeweging, zodat grotere hardmetalen gereedschappen met hogere voedingen kunnen worden ingezet terwijl gatkwaliteit en positioneringstoleranties strak blijven. Concreet gebruikt hij een 40 HP boorspindel tot 2.500 rpm, gekoppeld aan servodrives en precisie kogelomloopspil-positionering voor snelle, stabiele Z-asvoedingen — precies wat u nodig hebt voor zware platen en korte cycli.