Hello steel distributor!

Transform your business with Voortman

In the steel distribution sector, simply meeting demands isn't enough; adding value at every step is key to distinguishing your business. Your goal as a steel distributor is clear: provide your customers with complete, top-quality products while maintaining short lead times. That’s exactly where Voortman steps in with its diverse range of multi-processing machines and solutions.

Below you'll find more info on:

1. Becoming a value-adding one-stop-shop for your customers.

2. Maximizing logistical efficiency.

3. Creating transparency in your value chain with automation and digitization.

1. BECOME AN EFFICIENT, VALUE-ADDING ONE-STOP-SHOP

Imagine starting your day with an opportunity from a sought-after customer. The challenge? Their project needs extensive drilling and milling, and they want more than just cutting steel to length. They seek a full-package provider, with various in-house processes to enhance their business value. Shipping costs also add pressure - you need more than steel cutting to outpace competitors; it requires a holistic approach.

Your goal is simple: deliver complete, top-quality products to your customers with short lead times. In essence, you need to transform into a value-adding, one-stop-shop.

Consider these strategies to uplevel your business:

- Expand production processes: Incorporating more processes boosts your capabilities, making you a versatile service provider.

- Enhance flexibility: This enables you to cater to diverse customer needs, making your company a go-to solution for customers.

- Reduce manual handling and logistics: This improves efficiency, cuts costs, and accelerates production.

That's where Voortman steps in with its diverse range of multi-processing machines and solutions

2. MAXIMIZING LOGISTICAL EFFICIENCY

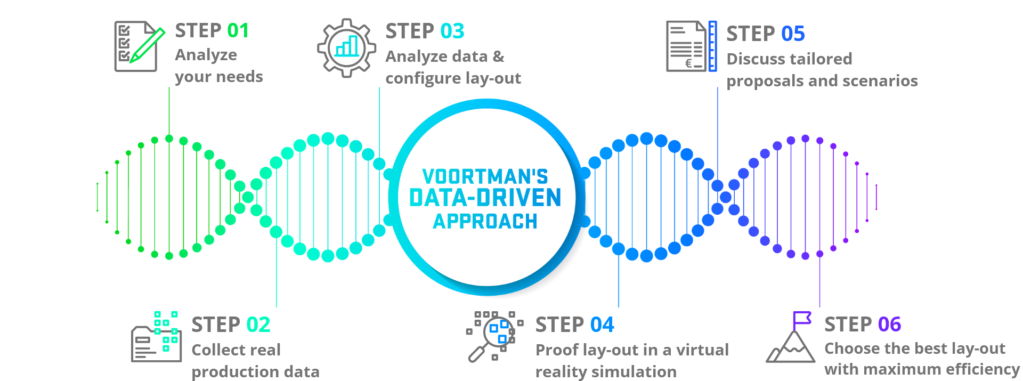

Although it might seem that adding more processes could potentially disrupt your workflow, this is a misconception. Voortman machines and software are designed for speed, efficiency, and seamless integration, ensuring your logistical process flow remains uninterrupted. Let's be honest, it's all about this perfect logistical flow! To come to such a perfect flow, Voortman's innovative data-driven approach and simulation software is implemented. By analyzing customer's actual "DNA" and production data, multiple scenarios are evaluated, ultimately ending up with the best and optimal lay-out solution.

An example at one of our customers

Finding the optimal logistical routing

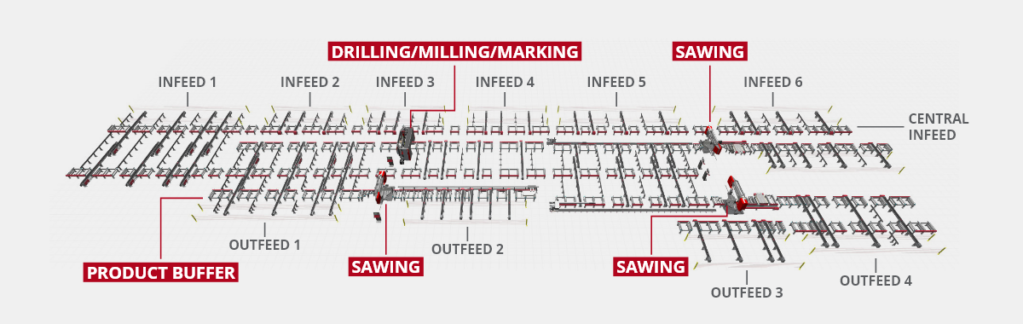

To better understand the importance of finding the perfect logistical routing, let's take an example from one of our customers that brings this subject matter to life. When we started at one of Finland's leading steel distributors, primary bottlenecks were found in the transportation of steel to their four outdated saws. This process relied heavily on manual operations, resulting in extended delivery times and soaring operational costs. Recognizing the need for optimization, a team of experts has successfully developed a highly efficient layout that enables the loading of profiles from six different halls onto various infeed zones. This innovative design revolves around strategically positioned infeed and outfeed locations, as well as the seamless integration of specialized machinery and streamlined processes.

Increased output, short lead times, enhanced competitiveness

The Voortman V631 drilling and milling machine and Voortman VB1250 band saws with an automatic short piece removal system effectively perform their tasks. Additionally, a dedicated route incorporating the Voortman VB1250 band saw featuring a backstop system, enables high-volume profile- and bundle cutting. Time-consuming material movements, bottlenecks, and complicated logistics are eliminated. With intelligent buffer management, load balancing principles, and efficient routing, the system can operate autonomously for extended periods, ensuring maximum throughput. Moreover, the sawing capacity has doubled twice and crane capacity is used more efficiently. The substantial increase in output marks a significant advancement in the logistics process, resulting in fast lead times and enhanced competitiveness – from stock to finished product.

3. CREATING TRANSPARENCY IN YOUR VALUE CHAIN

WITH AUTOMATION AND DIGITIZATION

Establishing all the necessary processes and logistical routing are essential - but why stop there? The final step is to ensure full transparency in your value chain. Not only for yourself but also for your customers. By integrating DIGI-STEEL's comprehensive digital solutions with your ERP system, utilizing VACAM's transparent machine control, and harnessing EVI's business insights, we are completely dedicated to assisting you on this path. Now, let's take a closer look at these digital solutions designed for different phases in your workflow.

Rainham Steel is running at full capacity

A major steel distributor in the UK

Rainham Steel, a major steel distributor in the UK since 1973, is committed to meeting its customers' demands in a timely and complete manner. With this in mind and the need to increase capacity, the company invested in a Voortman MSI line. A shot blasting and painting line combined with a drill-saw, blasts, drills and cuts profiles to length in full automation. Now that the system is running at full capacity, Rainham can take on more jobs than ever before and is even looking to expand further!