SANTOS & SMULDERS - Scaling production with precision and reliability

“I flew to the Netherlands to buy one machine, and came back with a full line.”

Paulo Santos

Owner, Santos and Smulders Group

Inspired by this testimonial?

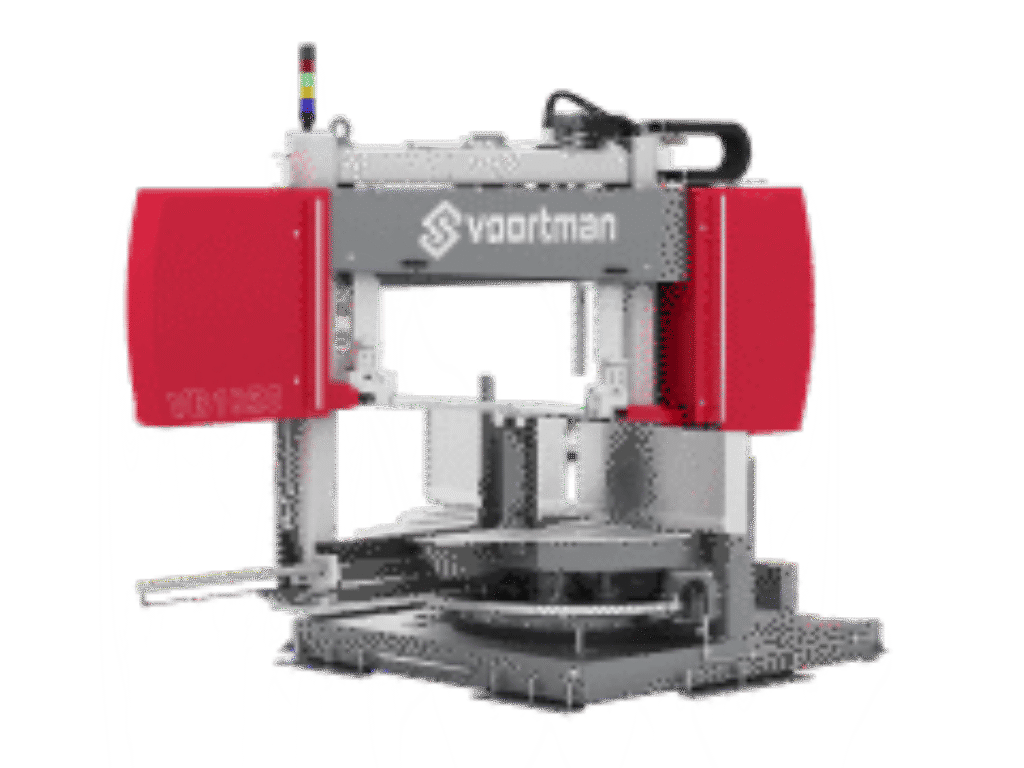

REFERENCED PRODUCTS

THE CHALLENGE

Paulo Santos grew up in a family-owned metalworking business in Portugal. Over time, the company expanded, taking on international projects, including a massive agro-industrial development in Angola covering nearly one million square meters. But with growth came new pressures. “The development of the local machines we had wasn’t enough,” Paulo recalls. Manual operations slowed production, and existing equipment couldn’t meet the precision and speed required.

ABOUT THE COMPANY

Santos and Smulders Group is a family-founded business based in Portugal with operations extending into Angola. Specializing in large-scale steel structures and silos, the company has grown from a small local workshop into a trusted international supplier. With around 60 employees in Portugal and nearly 200 across the group, including assembly and fabrication teams in Angola, the company is engaged in some of the region’s largest agro-industrial projects.

THE SOLUTION

Through his Dutch business partner, Paulo had long been familiar with the steel industry in the Netherlands. After visiting factories and watching Voortman machines in operation, he decided to make the leap. “I flew to the Netherlands to buy one machine,” he explains, “and came back with a full line.”

Today, his setup includes a V631 drilling and sawing line with VB1050, plus a V71 marking machine. He chose the back-to-back configuration because of its compact footprint. A crucial decision to save valuable workshop space while still achieving a highly efficient workflow .

To involve the next generation, Paulo even brought his sons along to the Netherlands to see the equipment firsthand. Their enthusiasm helped confirm the decision to invest in Voortman technology .

CONFIDENT FROM THE START

Installation of the Voortman line was straightforward and well-organized, with no unexpected setbacks. Paulo describes the process as smooth and efficient, allowing production to resume quickly. Training was another highlight. Voortman’s technicians provided thorough guidance both on-site and in the Netherlands, ensuring the operators felt confident from the start. “It was very easy for everyone to integrate and begin working. They all adapted very quickly,” Paulo says.

“If I had to go back and decide again, I’d buy Voortman every time. A winning team doesn’t need changing.”

Paulo Santos, owner Santos and Smulders Group

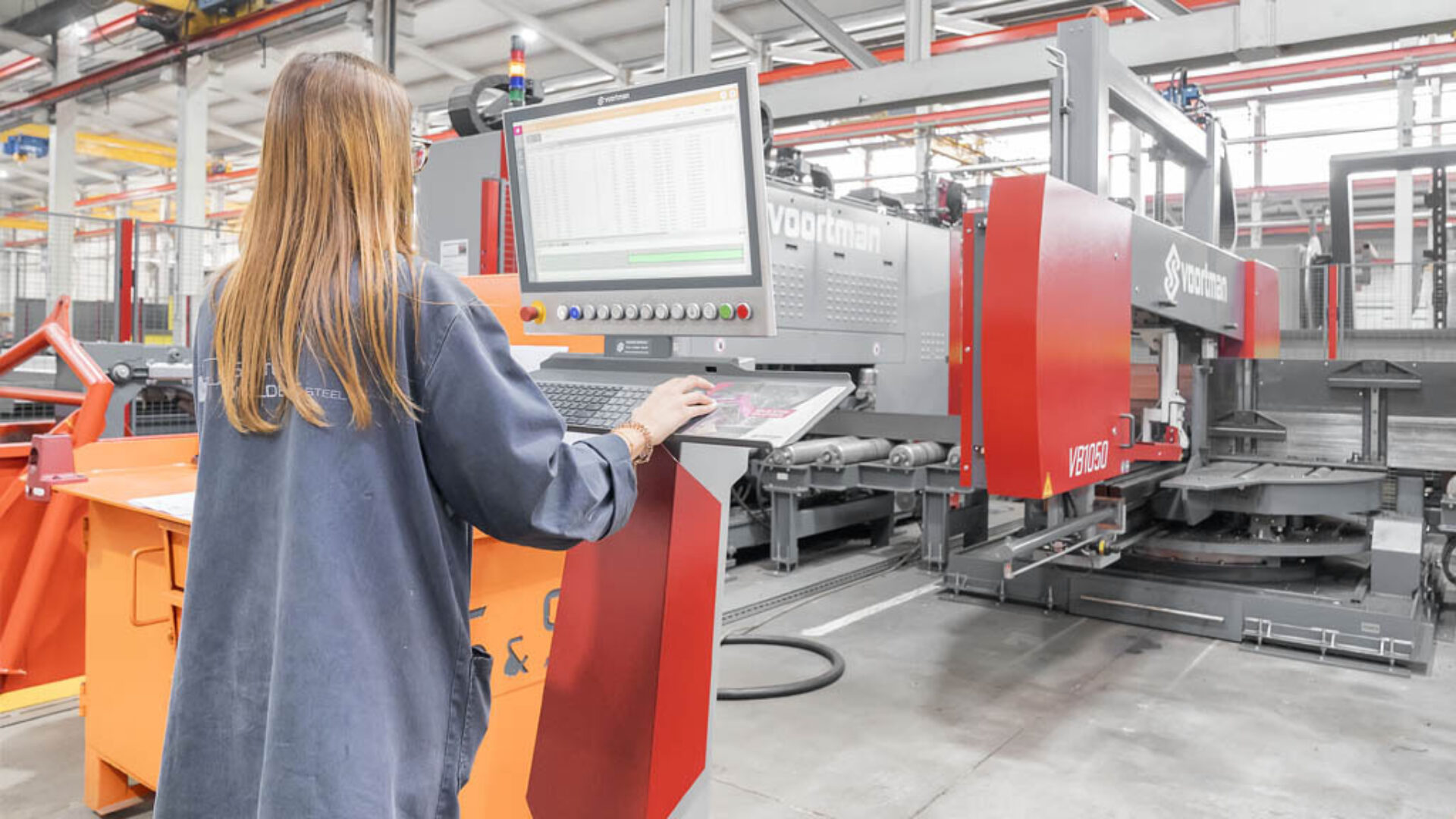

What stood out to him was how intuitive the machines are. Even staff with no prior background in CNC machinery could operate them with ease. “One of our operators is a young woman who had never worked with this kind of equipment before. She operates the machine without any difficulty,” he explains. This user-friendliness has helped the company train new employees faster, reducing reliance on highly specialized labor.

Equally important is the reliability of Voortman’s service. Downtime, once a common problem with older equipment, is now almost nonexistent. “If something goes wrong, we leave the machine on during lunch, and by the end of the day it’s solved,” Paulo notes. Remote access allows Voortman’s technicians to troubleshoot instantly, while replacement parts are shipped quickly and installed by Paulo’s own team. The responsiveness has given him confidence that his production line will not stand still.

NEW POSSIBILITIES

The impact has been dramatic. “Production has almost doubled - maybe ten times more than what was done by hand,” Paulo says. The precision of drilling and cutting has improved dramatically, ensuring millimeter accuracy even with slightly bent beams .

One of the biggest productivity boosts came from layout marking. The V631 automatically marks exact positions for plates and welds, eliminating guesswork. “It’s a huge help. You just bring the part, put it on the mark, and you know it’s right. No mistakes, no delays,” Paulo explains .

This automation not only speeds up fabrication but also reduces dependence on scarce skilled labor. Paulo estimates a five-year return on investment, faster than the industry average of seven years .

Looking ahead, he is already preparing to expand. The company has purchased land for two new production halls, with plans to add more automated and robotic equipment. “In the next decade, everything must be as robotic and process-driven as possible,” he says .

MORE TESTIMONIALS