CNC plasma table

Get superior cutting quality and efficiency with Voortman’s CNC plasma table solutions. Built for accuracy, speed, and reliability, these machines ensure seamless operation. You can cut a wide range of materials and thicknesses with ease. For both high-volume production and custom fabrication, you get outstanding results with minimal setup time.

Why choose a Voortman CNC plasma table?

- High-Speed cutting – Optimize productivity with rapid, precise plasma cutting

- Advanced CNC technology – Ensures consistent, repeatable accuracy for every cut

- Durable & reliable build – Engineered for long-lasting performance in demanding environments

- Smart software integration – Automate processes and streamline production with intelligent software

- Flexible material handling – Cut various material with ease

Get more out of your work with a CNC plasma table

Voortman CNC plasma tables give you the flexibility to handle various cutting applications. From structural components to custom designs, you get the precision you need. Automated height control, intelligent nesting, and autonomous running boost your efficiency. These features also help keep your workspace clean and safe. You achieve maximum precision and cost-effectiveness in both intricate details and high-speed production.

Take a look at the Voortman V310 in action

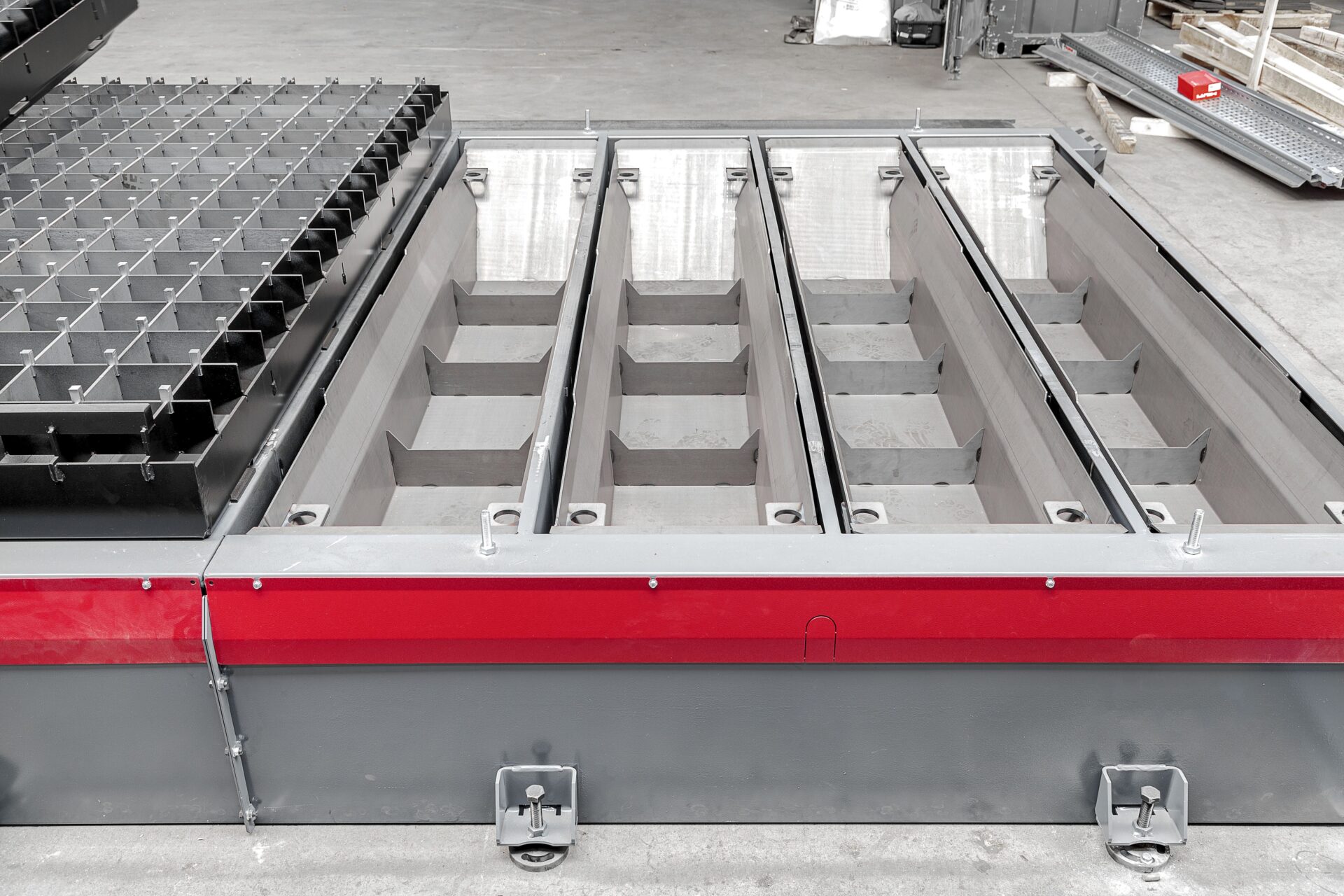

The Voortman V310 CNC plasma cutting and drilling machine means all known advanced technologies of our current range, plus extra additions. Equipped with a drill spindle, the V310 meets diversity and flexibility in processing where cutting, drilling and marking are carried out in one process list. Holes up to 40mm can be carbide drilled with the SK40 drill spindle.

FAQ

It's a computer-controlled cutting system, that uses a high-temperature plasma arc to cut through conductive materials such as steel. The CNC system ensures precision and repeatability, making it ideal for industrial and fabrication applications.

It cuts metal components with high accuracy and efficiency. Industries like manufacturing, construction, and metal fabrication widely use it. It helps create structural parts, machinery components, custom designs, and more. Plasma cutting processes thick materials quickly and cost-effectively, making it a valuable solution.